Preparation method of sintered samarium-cobalt magnet with ultrahigh maximum magnetic energy product

A technology with the largest magnetic energy product and samarium cobalt magnets, which is applied in the fields of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., and can solve problems such as low comprehensive pass rate, harsh conditions, and backward production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing an ultrahigh maximum energy product sintered samarium cobalt magnet, comprising:

[0033] 1) Ingot preparation:

[0034] Prepare samarium-cobalt alloy raw materials according to the following weight percentages: Sm: 25-27%, Fe: 15-27%, Zr: 2-5%, Cu: 3-8%, and the balance is Co;

[0035] Among the raw materials, Sm element mainly enters the main phase of the magnet, which is the key to the remanence and coercive force of the magnet. However, too much rare earth element will deteriorate the performance of the magnet, which needs to be adjusted through the control of particle size and oxygen content. Fe element content is the key to high remanence, and high remanence is the premise of high maximum energy product;

[0036] The prepared samarium-cobalt alloy raw materials are smelted in an intermediate frequency melting furnace according to the requirements of the feeding sequence, and then cast in a pan-cooled water-cooled copper mold to obtain an al...

example 1

[0057] 1) The ingot is composed of the following components: 25.3% by weight of Sm, 23.6% by weight of Fe, 2.5% by weight of Zr, 5.5% by weight of Cu and the balance being Co;

[0058] The preparation method of the alloy ingot is: configure the samarium-cobalt alloy raw material; melt the configured raw material in an intermediate frequency melting furnace, and then cast it in a plate-cooled water-cooled copper mold under the protection of high-purity argon (purity is 99.999%) , to prepare an alloy ingot with an average thickness of ~6mm;

[0059] 2) Milling

[0060] The ingot is mechanically crushed, medium crushed, and jet milled to prepare alloy powder;

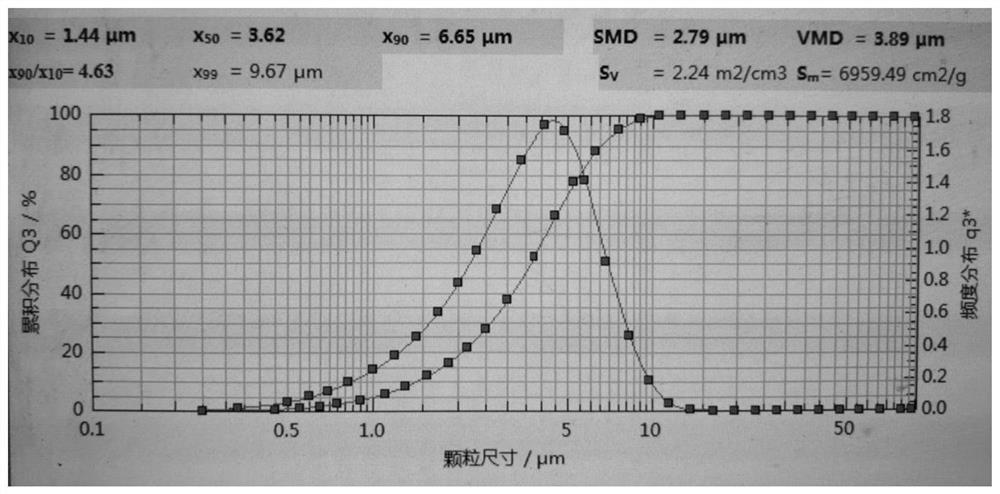

[0061] The average particle size of the alloy powder is 2.9 μm.

[0062] 3) mixed powder

[0063] The alloy powder in step 2) was added with 0.35‰ lubricant, and under the protection of nitrogen, in order to ensure uniform mixing, the time was controlled for 2.5 hours to prepare samarium-cobalt alloy powder.

[0064] 4...

example 2

[0069] 1) The ingot is composed of the following components: 25.7% by weight of Sm, 20.3% by weight of Fe, 2.7% by weight of Zr, 5.8% by weight of Cu and the balance being Co;

[0070] The preparation method of the alloy ingot is: configure the samarium-cobalt alloy raw material; melt the configured raw material in an intermediate frequency melting furnace, and then cast it in a plate-cooled water-cooled copper mold under the protection of high-purity argon (purity is 99.999%) , to prepare an alloy ingot with an average thickness of <6mm;

[0071]2) Milling

[0072] The ingot is mechanically crushed, medium crushed, and jet milled to prepare alloy powder;

[0073] The average particle size of the alloy powder is 2.7 μm;

[0074] 3) mixed powder

[0075] The alloy powder in step 2) was added with 0.27‰ lubricant, and under the protection of nitrogen, in order to ensure uniform mixing, the time was controlled for 2 hours to prepare samarium-cobalt alloy powder.

[0076] 4) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com