Vitamin K3 synthesis method and device

A synthesis method and vitamin technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of sulfonates, etc., can solve the problems of low product recovery rate, poor MNB stability, prolonged reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

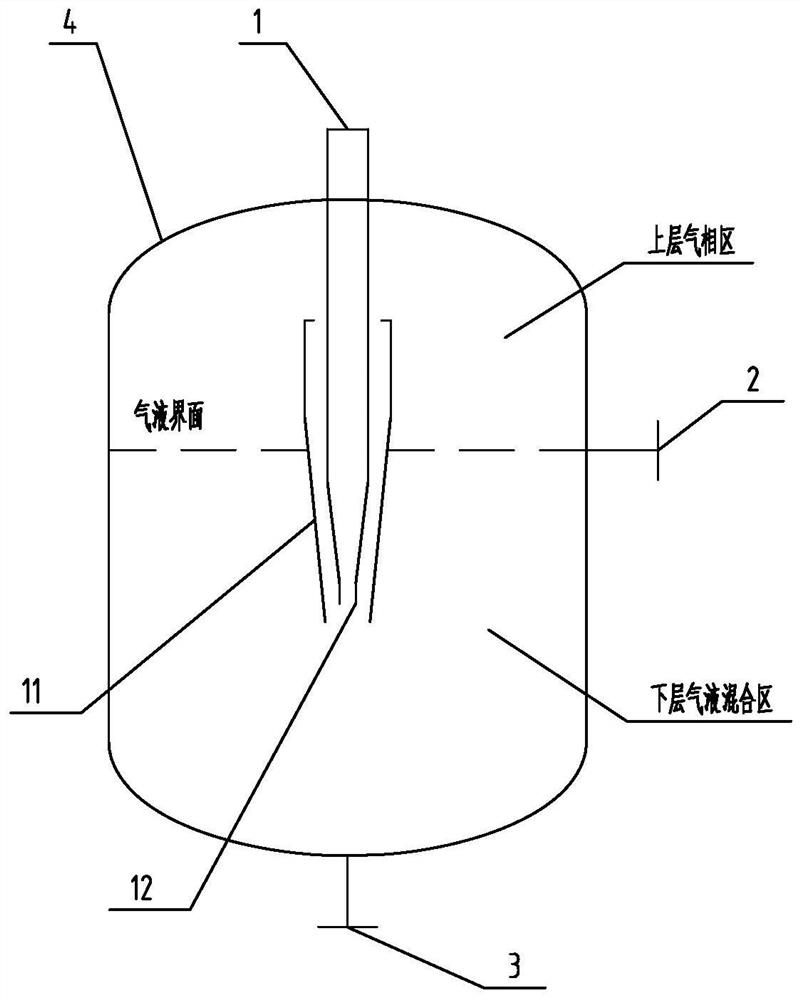

[0042] A kind of synthetic method of vitamin K3, the concrete steps of this method are:

[0043] Preparation of S1, intermediate β-menadione

[0044] 1. β-methylnaphthalene, sulfuric acid, sodium dichromate, and water continuously enter the jet flow continuous oxidation reactor, the flow rate of β-methylnaphthalene is 30kg / h, the flow rate of sulfuric acid is 240kg / h, and the feeding amount of sodium dichromate is 300kg / h, the batching water flow rate is 200kg / h, the temperature of the reaction solution is controlled at 50±1°C, and the residence time is 10h to obtain the oxidation reaction solution of β-menadione.

[0045] In the initial reaction system, the concentration of each substance is: β-methylnaphthalene 68.6g / L, sulfuric acid 549g / L, sodium dichromate 686.3g / L.

[0046] 2. The oxidation reaction solution obtained in the previous step is continuously filtered into the filter and washed with water, and the washing water volume is 400kg / h;

[0047] 3. Wash the filter ...

Embodiment 2

[0059] A method for synthesizing vitamin K3 is based on Example 1, reducing the residence time of the oxidation reaction and reducing the reaction temperature; after the MSB reaction solution is used to prepare MSB, co-production is still used to prepare MNB.

[0060] Preparation of S1, intermediate β-menadione

[0061] 1. β-methylnaphthalene, sulfuric acid, sodium dichromate, and water continuously enter the jet flow continuous oxidation reactor, the flow rate of β-methylnaphthalene is 150kg / h, the flow rate of sulfuric acid is 1200kg / h, and the feeding amount of sodium dichromate is 1400kg / h, the batching water flow rate is 700kg / h, the temperature of the reaction solution is controlled at 35±1°C, and the residence time is 2h.

[0062] In the initial reaction system, the concentration of each substance is: β-methylnaphthalene 71.7g / L, sulfuric acid 573.9g / L, sodium dichromate 669.6g / L.

[0063] 2. The oxidation reaction solution obtained in the previous step is continuously...

Embodiment 3

[0076] A method for synthesizing vitamin K3 is based on Example 1, reducing the residence time of the oxidation reaction and increasing the reaction temperature; the MSB reaction solution is divided by 50% to prepare MSB and then co-produced to prepare MNB.

[0077] Preparation of S1, intermediate β-menadione

[0078] 1. β-methylnaphthalene, sulfuric acid, sodium dichromate, and water continuously enter the jet flow continuous oxidation reactor, the flow rate of β-methylnaphthalene is 100kg / h, the flow rate of sulfuric acid is 800kg / h, and the feeding amount of sodium dichromate is 900kg / h, the batching water flow rate is 3000kg / h, the temperature of the reaction solution is controlled at 65±1°C, and the residence time is 1.5h.

[0079] In the initial reaction system, the concentration of each substance is: β-methylnaphthalene 34.4g / L, sulfuric acid 275g / L, sodium dichromate 309.4g / L.

[0080] 2. The oxidation reaction solution obtained in the previous step is continuously fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com