Recycling method of fluorine-containing sulfuric acid waste liquid

A sulfuric acid waste liquid and recycling technology, which is applied in the field of resource recycling of fluorine-containing sulfuric acid waste liquid, can solve problems such as difficult separation of calcium sulfate and calcium fluoride, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

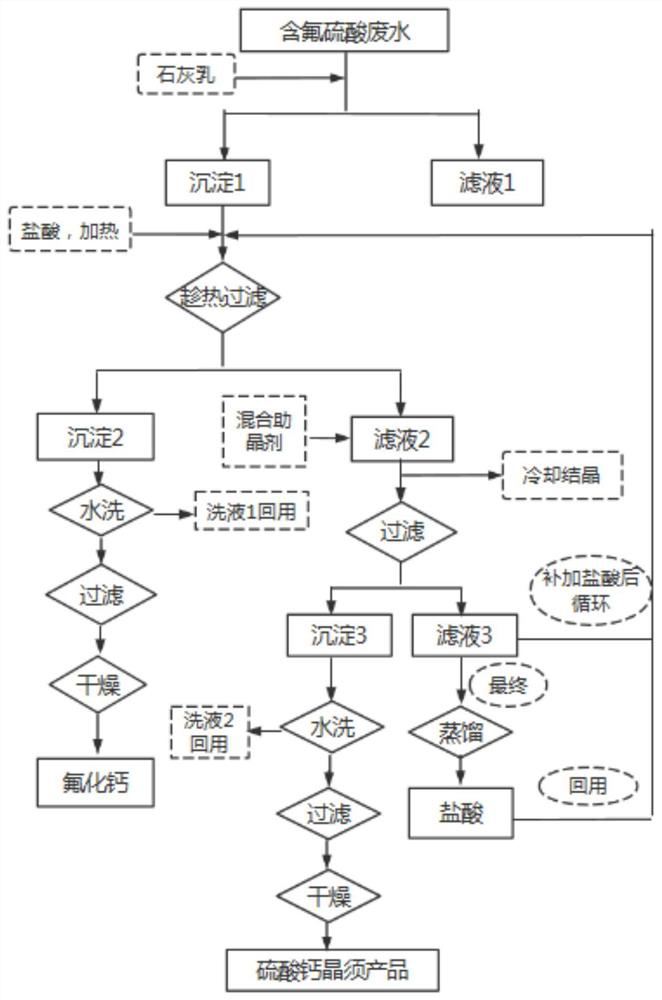

Method used

Image

Examples

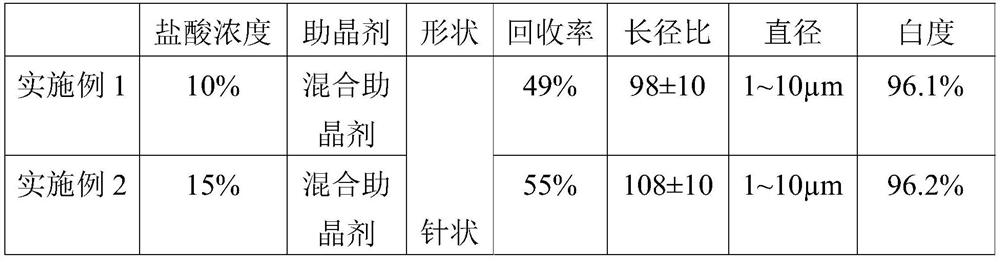

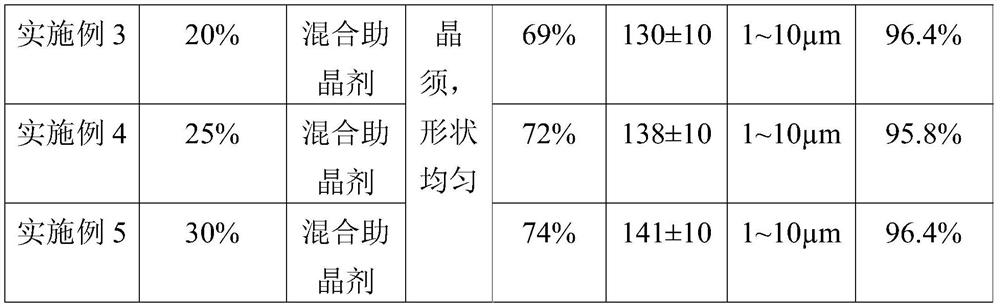

Embodiment 1

[0035] Take 1000mL of a fluorine-containing sulfuric acid waste liquid (fluorine content 12g / L, sulfuric acid content 30%), add milk of lime to the waste liquid, adjust the pH of the solution to 8, stir well and then filter to obtain a filter cake, which is calcium fluoride and calcium sulfate mixture. Add 10wt% hydrochloric acid to the mixture of calcium fluoride and calcium sulfate with a mass volume ratio of 1:0.02g / L, then heat and stir at 80°C, then add 0.675g of mixed crystal aid (stearic acid: magnesium chloride mass The ratio is 1:1), after stirring for 1 hour, filter while hot, the obtained filter cake is washed with water, filtered, and dried to obtain 22.62g of calcium fluoride product, the filtrate is cooled at room temperature for 4 hours, filtered, the obtained filter cake is washed with water, filtered , and dried at 50°C to obtain 313.47g of calcium sulfate whisker product.

Embodiment 2

[0037] Take 1000mL of a fluorine-containing sulfuric acid waste liquid (fluorine content 12g / L, sulfuric acid content 30%), add milk of lime to the waste liquid, adjust the pH of the solution to 8, stir well and then filter to obtain a filter cake, which is calcium fluoride and calcium sulfate mixture. Add 15wt% hydrochloric acid to the mixture of calcium fluoride and calcium sulfate with a mass volume ratio of 1:0.02g / L, then heat and stir at 80°C, then add 0.675g of mixed crystal aid (stearic acid: magnesium chloride mass The ratio is 1:1), after stirring for 1 hour, filter while hot, the obtained filter cake is washed with water, filtered, and dried to obtain 23.17g of calcium fluoride product, the filtrate is cooled at room temperature for 4 hours, filtered, the obtained filter cake is washed with water, filtered , dried at 50°C to obtain 351.85g of calcium sulfate whisker product.

Embodiment 3

[0039]Take 1000mL of a fluorine-containing sulfuric acid waste liquid (fluorine content 12g / L, sulfuric acid content 30%), add milk of lime to the waste liquid, adjust the pH of the solution to 8, stir well and then filter to obtain a filter cake, which is calcium fluoride and calcium sulfate mixture. Add 20wt% hydrochloric acid to the mixture of calcium fluoride and calcium sulfate with a mass volume ratio of 1:0.02g / L, then heat and stir at 80°C, then add 0.675g of mixed crystal aid (stearic acid: magnesium chloride mass The ratio is 1:1), after stirring for 1 hour, filter while hot, the obtained filter cake is washed with water, filtered, and dried to obtain 22.36g of calcium fluoride product, the filtrate is cooled at room temperature for 4 hours, filtered, the obtained filter cake is washed with water, filtered , dried at 50°C to obtain 441.41g of calcium sulfate whisker product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com