Composite heat stabilizer, chlorinated polyvinyl chloride pipe and preparation method of chlorinated polyvinyl chloride pipe

A technology of chlorinated polyvinyl chloride and composite heat stabilizer, which is applied in the field of composite heat stabilizer, chlorinated polyvinyl chloride pipe and its preparation, and can solve the problem of high melt viscosity and increased brittleness of mechanical properties of chlorinated polyvinyl chloride resin , low thermal stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a kind of preparation method of chlorinated polyvinyl chloride pipe, it comprises the following steps:

[0032] S1. According to the mass parts of the above-mentioned components, weigh 1000g of chlorinated polyvinyl chloride resin, 90g of composite heat stabilizer, 30g of lubricant, 100g of impact modifier, 50g of inorganic filler, 0.5g of coupling agent, and pigment 50g, spare;

[0033] Among them, the composite heat stabilizer includes organotin heat stabilizer, zinc stearate, calcium stearate and magnesium aluminum hydrotalcite; organotin heat stabilizer, zinc stearate, calcium stearate and magnesium aluminum hydrotalcite The mass ratio is 1:1.2:4.8:2; the organotin heat stabilizer is tin methyl mercaptide;

[0034] The lubricant is a mixture of stearic acid, oxidized polyethylene wax, and ethylene bis-stearamide; the mass-number ratio of stearic acid, ethylene bis-stearamide, and oxidized polyethylene wax is 1:5:4;

[0035] The impact modi...

Embodiment 2~8

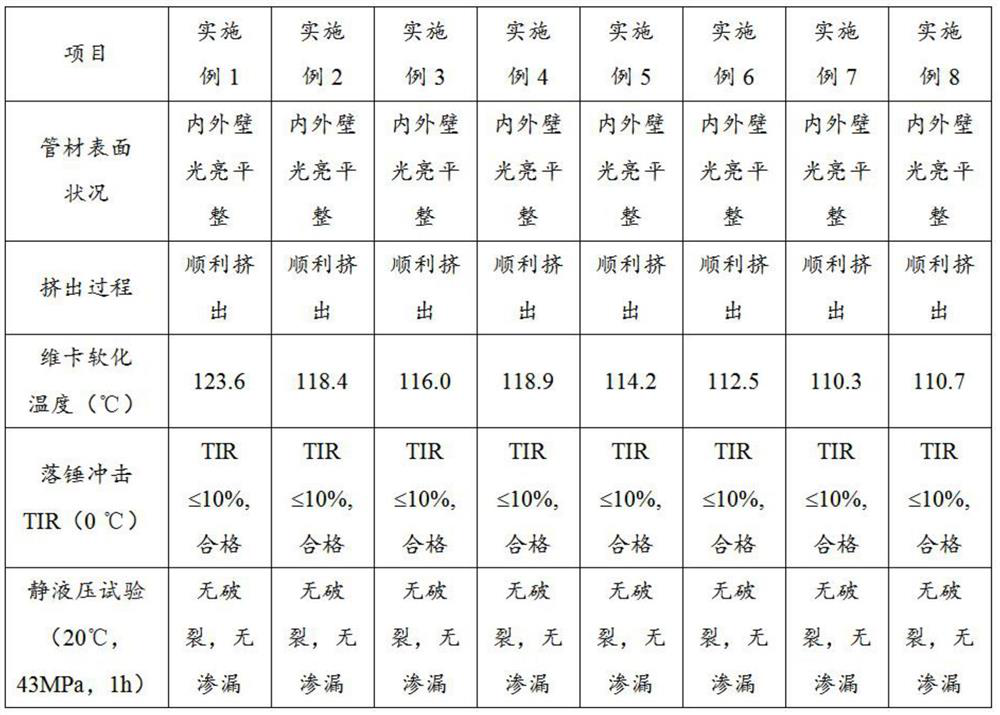

[0039] The preparation methods and process parameters adopted in Examples 2-8 are the same as those in Example 1, the difference is that the amounts of each component are different. Specifically, the components and their amounts used in Examples 1-8 are shown in Table 1 .

[0040] Table 1

[0041]

Embodiment 9

[0043] This embodiment provides a kind of preparation method of chlorinated polyvinyl chloride pipe, it comprises the following steps:

[0044] S1. According to the mass parts of the above-mentioned components, weigh 1000g of chlorinated polyvinyl chloride resin, 40g of composite heat stabilizer, 30g of lubricant, 80g of impact modifier, 10g of inorganic filler, 0.5g of coupling agent, and pigment 5g, spare;

[0045] Among them, the composite heat stabilizer includes organotin heat stabilizer, zinc stearate, calcium stearate and magnesium aluminum hydrotalcite; organotin heat stabilizer, zinc stearate, calcium stearate and magnesium aluminum hydrotalcite The mass ratio is 1:0.5:1:0.5; the organic tin heat stabilizer is a mixture of equal mass ratios of dimethyl tin chloride, butyl tin mercaptide, and dibutyl tin dichloride; the lubricant is stearate acid monoglyceride; the impact modifier is an acrylic ester copolymer; the inorganic filler is an equal mass ratio mixture of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com