Packaging adhesive film and preparation method and application thereof

A technology for encapsulating adhesive films and cross-linking aids, which is applied in the direction of adhesives, films/sheets without carriers, film/sheet-shaped adhesives, etc., which can solve the problems of high energy consumption, unsuitable photovoltaic modules, and lamination. Problems such as high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

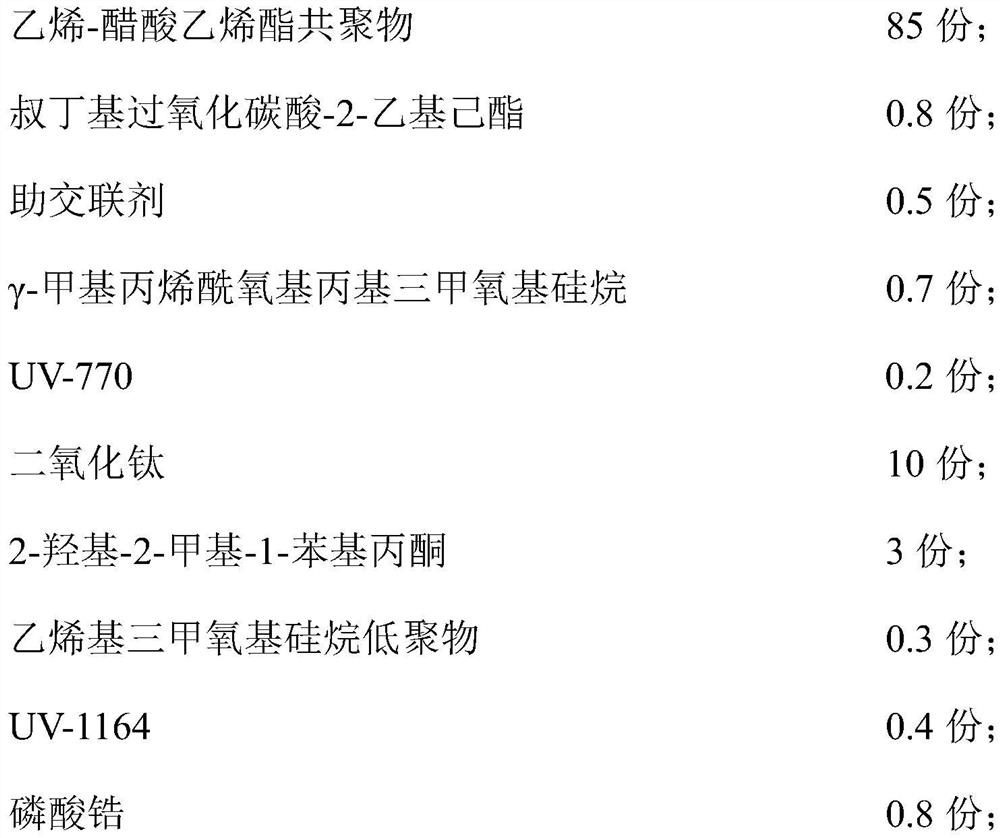

[0066] This embodiment provides an encapsulating adhesive film and a preparation method thereof, wherein the encapsulating adhesive film includes the following raw material components in parts by weight:

[0067]

[0068] The auxiliary crosslinking agent is composed of triallyl isocyanurate and trimethylolpropane triacrylate in a mass ratio of 1:2.

[0069] The preparation method of the above-mentioned packaging film is as follows:

[0070] Ethylene-vinyl acetate copolymer, tert-butyl peroxycarbonate-2-ethylhexyl, co-crosslinking agent, γ-methacryloxypropyltrimethoxysilane, UV-770, titanium dioxide, 2 -Hydroxy-2-methyl-1-phenylacetone, vinyltrimethoxysilane oligomer, UV-1164 and zirconium phosphate were mixed for 4 hours at 28°C, and then extruded at 70°C to obtain the encapsulant membrane.

Embodiment 2

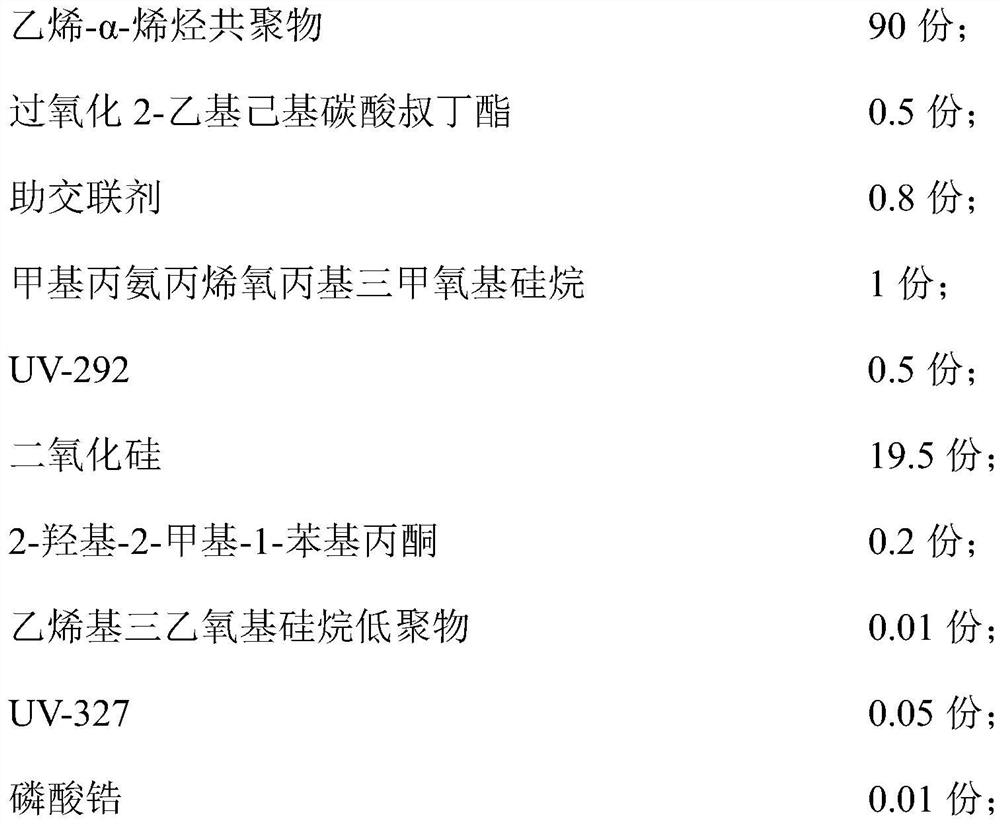

[0072] This embodiment provides an encapsulating adhesive film and a preparation method thereof, wherein the encapsulating adhesive film includes the following raw material components in parts by weight:

[0073]

[0074] The auxiliary crosslinking agent is composed of triallyl cyanurate and ethoxylated trimethylolpropane triacrylate in a mass ratio of 1:0.2.

[0075] The preparation method of the above-mentioned packaging film is as follows:

[0076] Ethylene-α-olefin copolymer, tert-butyl peroxide 2-ethylhexyl carbonate, co-crosslinking agent, methyl alanyloxypropyltrimethoxysilane, UV-292, silicon dioxide, 2-hydroxy - After mixing 2-methyl-1-phenylacetone, vinyltriethoxysilane oligomer, UV-327 and titanium phosphate for 3 hours at 30°C, extrude at 80°C to obtain the packaging film .

Embodiment 3

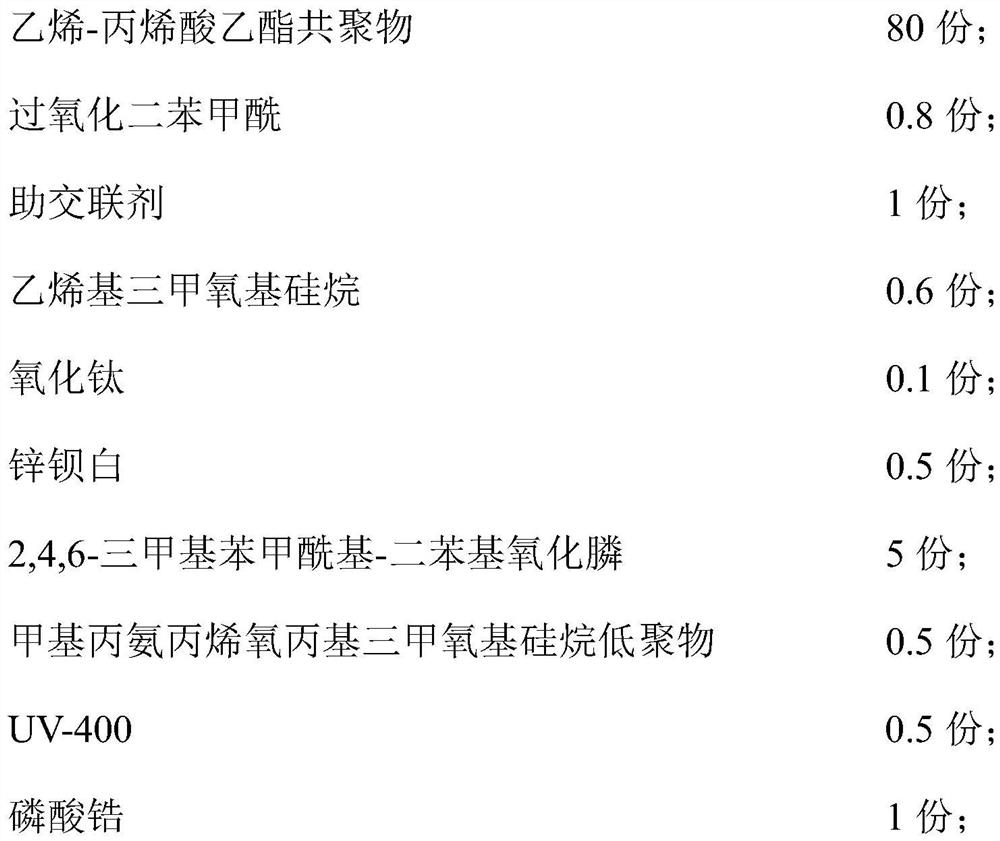

[0078] This embodiment provides an encapsulating adhesive film and a preparation method thereof, wherein the encapsulating adhesive film includes the following raw material components in parts by weight:

[0079]

[0080] The auxiliary crosslinking agent is composed of triallyl cyanurate and ethoxylated pentaerythritol tetraacrylate in a mass ratio of 1:5.

[0081] The preparation method of the above-mentioned packaging film is as follows:

[0082] Ethylene-ethyl acrylate copolymer, dibenzoyl peroxide, co-crosslinking agent, vinyltrimethoxysilane, titanium oxide, lithopone, 2,4,6-trimethylbenzoyl-diphenyl phosphine oxide, methoxypropyltrimethoxysilane oligomer, UV-400 and zirconium phosphate were mixed at 40° C. for 6 hours, and then extruded at 80° C. to obtain the encapsulation film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com