Method for preparing photo-thermal fibers through microfluid air jet spinning

A photothermal fiber and microfluidic technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of only 60% photothermal conversion efficiency, cumbersome preparation process, low safety factor, etc. Excellent evaporation performance, simple synthesis method, green material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

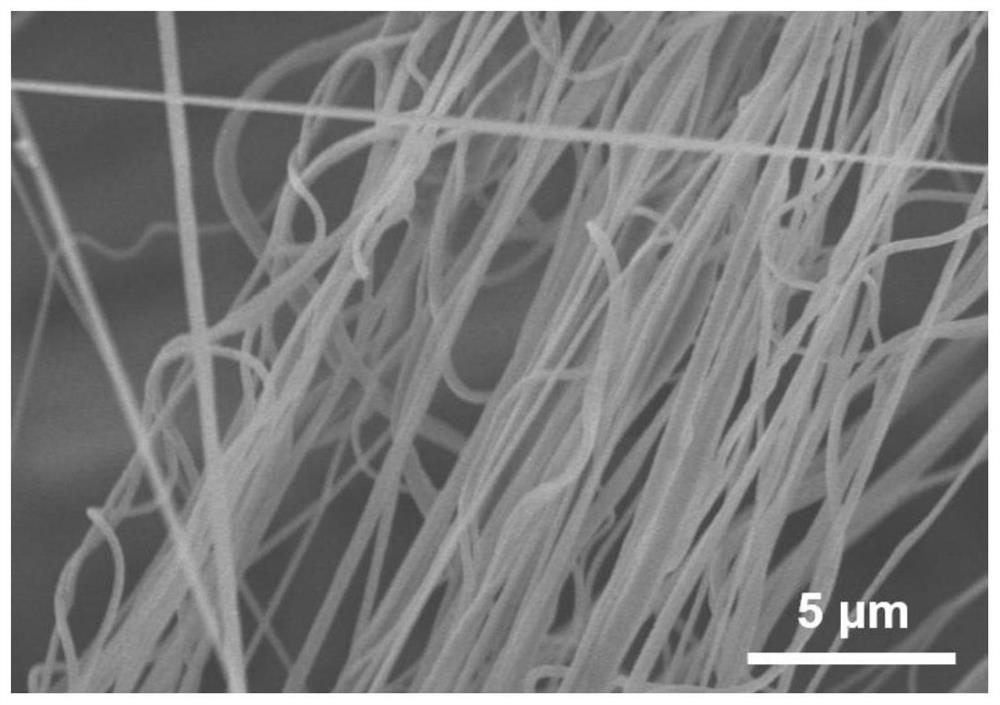

[0025]Example 1: 10 g of thermoplastic polyurethane is dissolved in 90 g of 99.9% N, N-dimethylformamide forms a mass fraction of 10% spun liquid. The spinning system is loaded into a 20 ml syringe fixed in the microfluid pump. Set the flow rate of the microfluid pump to 1mlh-1The distance from the needle to the receiver is set to 20 cm. The air pump blows air from the pinhole in a pressure of 0.05 MPa, and a thermoplastic polyurethane fiber film is obtained on the receiver. Fiber shapefigure 1 As shown, the fiber diameter is about 200 nm. The ambient temperature is 20 ° C, the humidity is 55%.

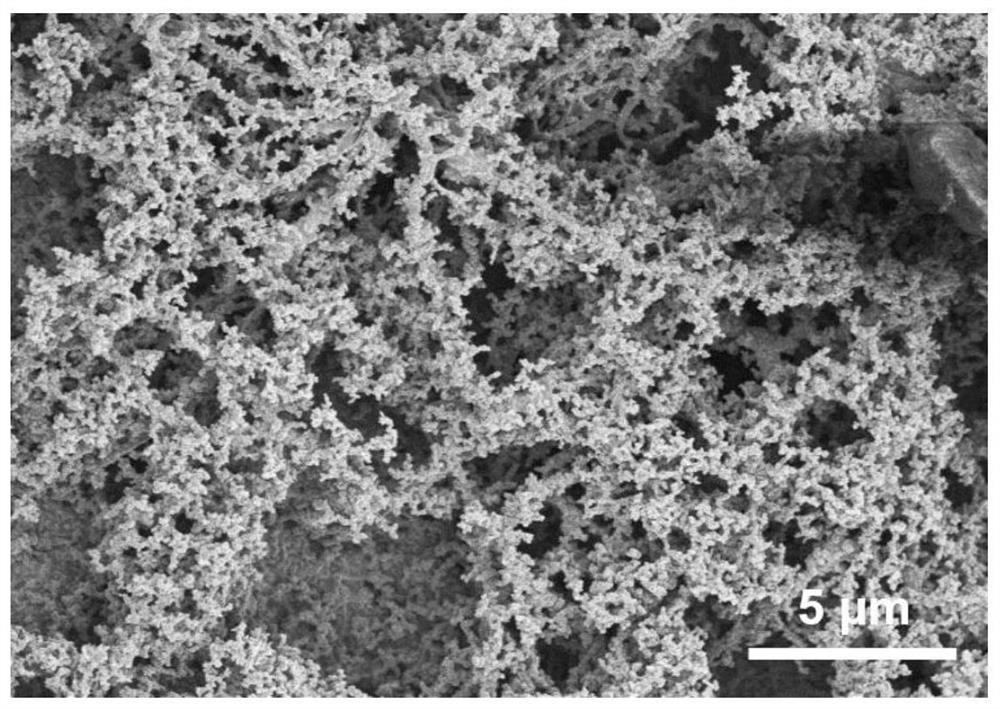

[0026]1 g of ferric chloride was dissolved in 150 g of water to form a ferric chloride solution, and then the fiber membrane was placed in a solution. A 1 g pyrrole solution was added dropwise, and the ice bath was 0.5 hours, and the obtained photothermal fiber membrane was washed twice with water, 40 ° C drying, removing unreacted monomers and free particles, such asfigure 2 As shown, for the...

example 2

[0028]Example 2: 13 g of polyamide 66 is dissolved in 87 g 88% formic acid forming mass fraction of 13% spinning liquid. The spinning system is loaded into a 20 ml syringe fixed in the microfluid pump. Set the flow rate of the microfluid pump to 5 ml h-1The distance from the needle to the receiver is set to 35 cm. The air pump blows air from the pinhole in a pressure of 0.1 MPa, obtaining a polyamide 66 fiber film on the receiver. The ambient temperature is 25 ° C, the humidity is 58%.

[0029]2 g of iron sulfate was dissolved in 150 g of water to form a ferrous sulfate solution, and then the fiber membrane was placed in a solution. The 1.5 g of aniline solution was added dropwise, and the ice bath was 0.5 ° C for 1 hour, and the obtained photothermal fiber membrane was washed 5 times, 45 ° C drying, removing the unreacted monomer and free particles to obtain a photothermal conversion fiber membrane.

[0030]Subsequent photothermal water evaporation experiments under xenon lamp, the water...

example 3

[0031]Example 3: 15 g of polyacrylonitrile dissolved in 85 g of 99.9% N, N-dimethylformamide forming mass fraction of 15% spinning liquid. The spinning system is loaded into a 20 ml syringe fixed in the microfluid pump. Set the flow of the microfluid pump to 3mlh-1The distance from the needle to the receiver is set to 25 cm. The air pump blows air from the pinhole in a pressure of 0.1 MPa, and the polyacrylonitrile fiber membrane is obtained on the receiver. The ambient temperature is 27 ° C, and the humidity is 60%.

[0032]3 g of iron nitrate was in 150 g of water to form a nitrate solution, and then the fiber membrane was placed in a solution. A 2 g of a dopamine solution was added dropwise, and the ice bath was 0 ° C for 2 hours, the obtained photothermal fiber membrane was washed 4 times with ethanol, 50 ° C, and the unreacted monomer and free particles were removed to obtain a photothermal conversion fiber membrane.

[0033]Subsequent photothermal water evaporation experiments under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com