Coarse-denier high-strength medium-modulus polyacrylonitrile-based carbon fiber and preparation method thereof

A polyacrylonitrile-based carbon fiber and polyacrylonitrile spinning technology, which is applied in the fiber field, can solve the problems of difficult preparation of highly crystalline and oriented polyacrylonitrile precursors, limited crystallization, drafting and orientation, and difficult control of fiber surface defects. Achieve the effects of reducing fiber surface defects, reducing radial skin-core structure differences, and slowing down curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

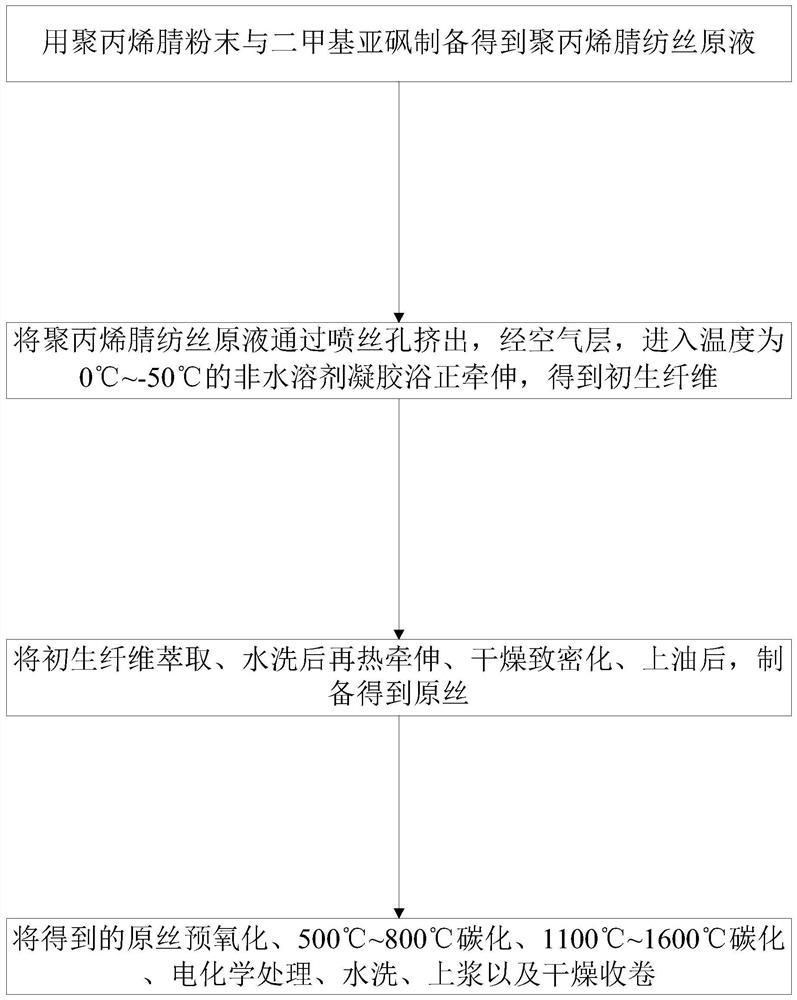

[0037] A preparation method of polyacrylonitrile-based carbon fiber, such as figure 1 shown, including the following steps:

[0038] S1: Prepare polyacrylonitrile spinning dope by mixing polyacrylonitrile powder with organic solvent;

[0039] S2: Extrude the polyacrylonitrile spinning stock solution through the spinneret hole, enter the non-aqueous solvent gel bath with a temperature of 0°C to -50°C, and then draw it to obtain the primary fiber;

[0040] S3: extracting the primary fiber, washing it with water, hot drawing at 40-95°C, drying and densifying, and oiling, to prepare the original silk;

[0041] S4: Pre-oxidize the obtained raw silk, carbonize at 500°C to 800°C, carbonize at 1100°C to 1600°C, electrochemically treat, wash with water, sizing, and dry and wind up.

Embodiment 1

[0043] (1) Preparation of polyacrylonitrile-methyl acrylate PAN-MA powder:

[0044] Using acrylonitrile (AN) as raw material, add methyl acrylate (MA) with a mass ratio of 96:4, add 20wt% of the total mass percentage into the water phase polymerization reactor, and use 0.3mol% water system oxidation-reduction initiation agent (ammonium persulfate-ammonium bisulfite) was polymerized at 40°C for 6 hours at a constant temperature, and the formed slurry was filtered, washed twice, and dried with hot air at 90°C until the water content was lower than 5wt%, and polyacrylonitrile-methyl acrylate PAN was obtained. - MA powder.

[0045] (2) Preparation of polyacrylonitrile spinning dope:

[0046] The polyacrylonitrile-methyl acrylate PAN-MA (3.4wt%) powder with a molecular weight of 150,000 was mechanically ground to below 100 mesh, mixed with DMSO at 19°C and mechanically stirred (speed 800rpm) to prepare a solid content of 20.5 The wt% dispersion liquid is vacuumed to 40KPa, slowly...

Embodiment 2

[0058] This embodiment is basically the same as Embodiment 1, the difference is:

[0059] (1) Preparation of polyacrylonitrile-itaconic acid PAN-IA powder

[0060] Acrylonitrile (AN) is used as raw material, and itaconic acid (IA) is added with a mass ratio of 98:2.

[0061] (2) Preparation of polyacrylonitrile spinning dope:

[0062] The polyacrylonitrile-itaconic acid PAN-IA (1.8wt%) powder with a molecular weight of 150,000 was mixed with DMF, and a dispersion liquid with a solid content of 24wt% was prepared by the same method as in Example 1, and the subsequent steps were the same as those in Example 1. 1, the polyacrylonitrile PAN spinning stock solution was obtained, and the viscosity of the polyacrylonitrile PAN spinning stock solution at room temperature was 112 Pa.s.

[0063] (3) Preparation of primary fibers

[0064] During the spinning process, the temperature of the polyacrylonitrile PAN spinning stock solution is kept at 50 °C, and it is transported to the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com