Preparation method of porous covalent organic framework material with triazine structure

A technology of covalent organic framework and triazine is applied in the field of preparation of porous covalent organic framework materials, which can solve the problems to be improved, and achieve the effects of good spatial structure stability, high yield and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation method of a porous covalent organic framework material with a triazine structure

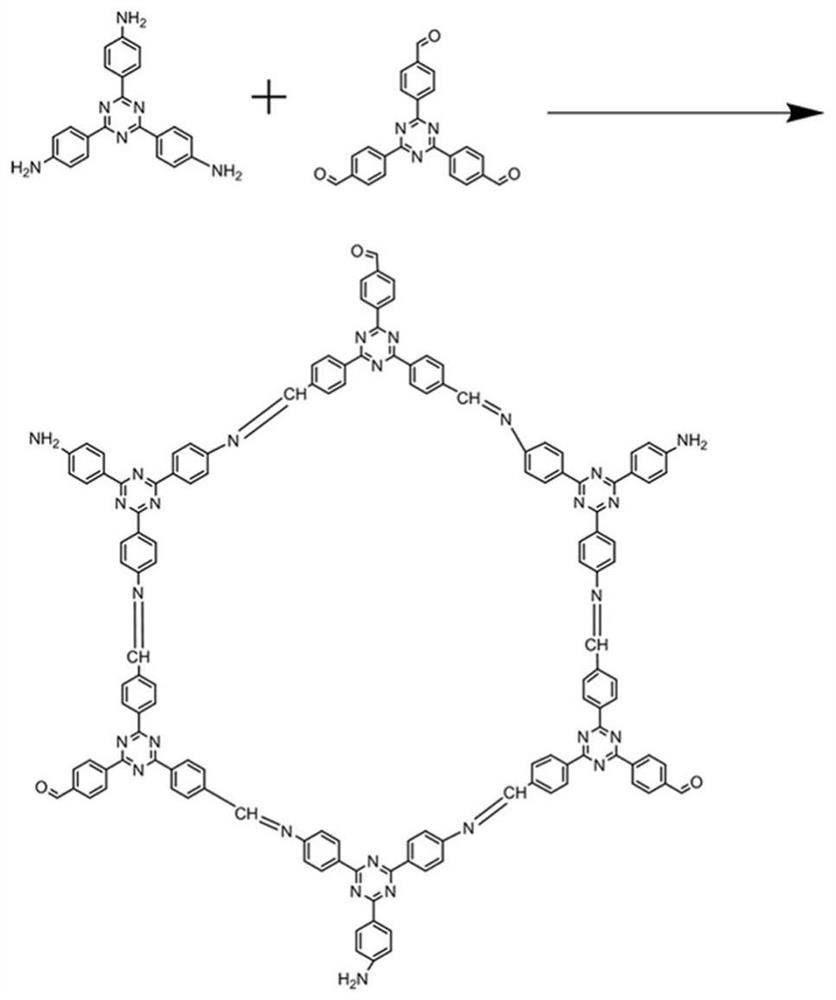

[0039] The synthetic reaction formula of present embodiment is as figure 1 As shown, it proceeds in the following steps:

[0040] S1. Mix 0.01772 g (5 mmol) 2,4,6-tris(4-aminophenyl)-1,3,5-triazine with 0.01967 g (5 mmol) 2,4,6-tris(4-formylbenzene base)-1,3,5-triazine (molar ratio 1 : 1) was dissolved in 11 mL of dioxane-mesitylene-acetic acid mixed solvent (the volume ratio between the three solvents was 5 : 5 : 1 ) and sonicate for 30 min to obtain system A1;

[0041] S2. Add 0.002775g of anhydrous calcium chloride (water removal agent) to system A1 for dehydration, then transfer to a stainless steel autoclave, pass in argon, and conduct a solvothermal reaction at 120°C for 72 h under an argon atmosphere , to obtain product B1;

[0042] S3. The product B1 was washed with N,N-dimethylformamide first, then with ethanol, and repeated washing three times. After th...

Embodiment 2~8

[0055] Examples 2-8 Preparation method of porous covalent organic framework material with triazine structure

[0056] Examples 2 to 8 are respectively a preparation method of a porous covalent organic framework material with a triazine structure, and their preparation steps are basically the same as in Example 1, the only difference lies in the amount of raw materials and process parameters. For details, see The following table:

[0057]

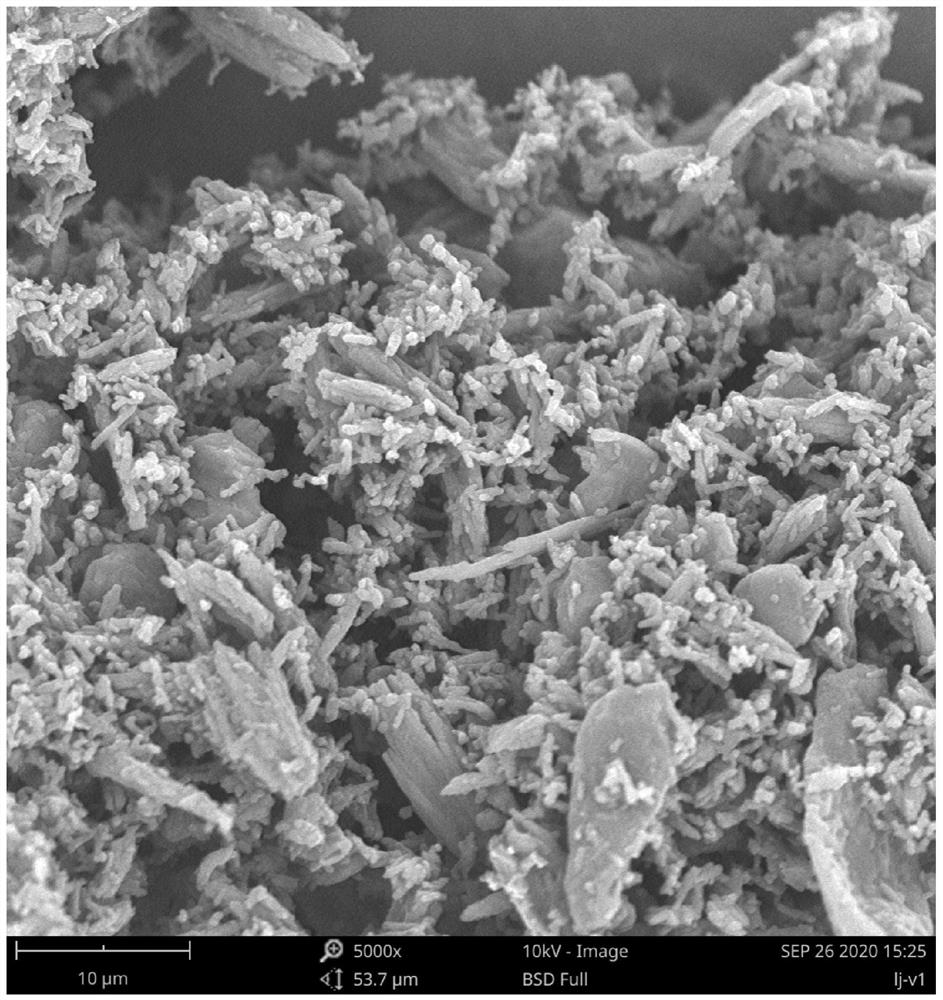

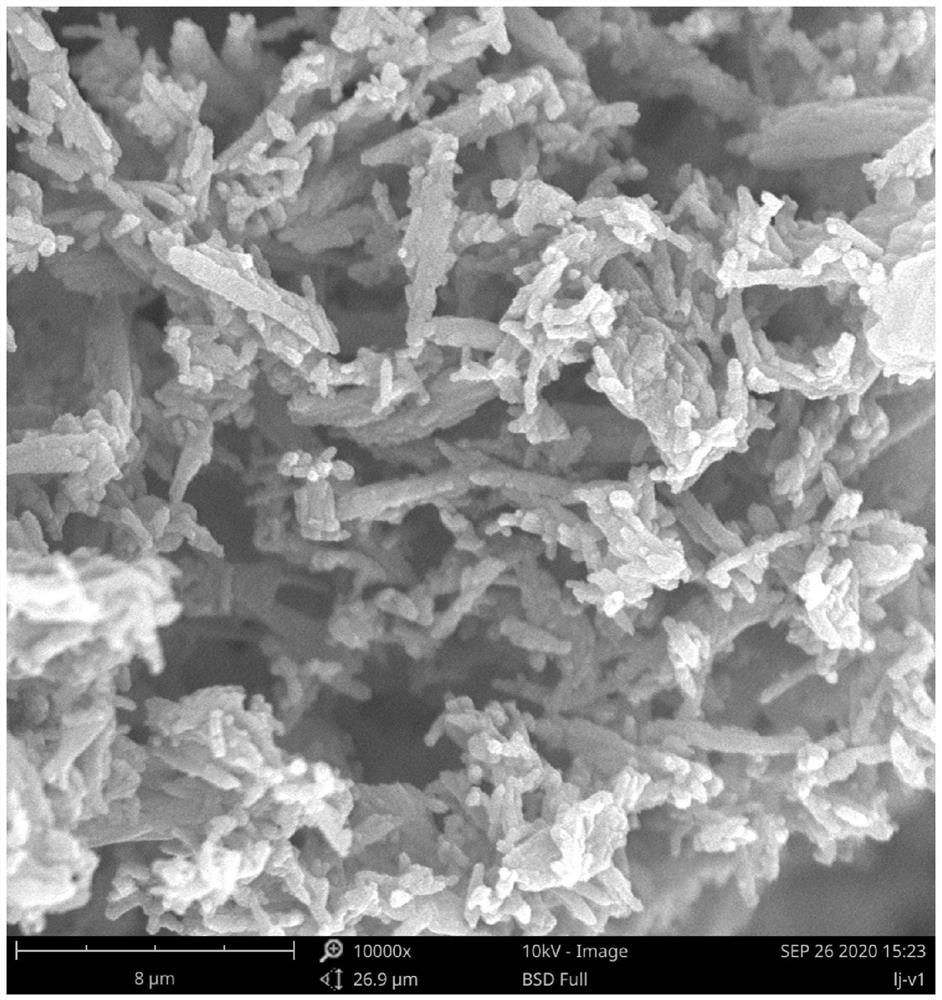

[0058] Among the F2~F8 materials, three kinds were randomly selected for morphology characterization analysis. Figure 9 For the scanning electron micrograph of the F3 material prepared in Example 3, the magnification is 20000 times; Figure 10 For the scanning electron micrograph of the F5 material prepared in Example 5, the magnification is 20000 times; Figure 11 The scanning electron microscope image of the F7 material prepared for Example 7 has a magnification of 20,000 times; it can be seen that the COF materials prepared by the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com