Preparation of alkali-modified biochar and application of alkali-modified biochar in removal of emerging pollutants in sewage

A biochar, alkali modification technology, applied in the field of environmental protection and comprehensive utilization of waste resources, can solve the problems of secondary pollution, high cost of treatment process, incomplete removal of emerging pollutants, etc., and achieves less secondary pollution and operation. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

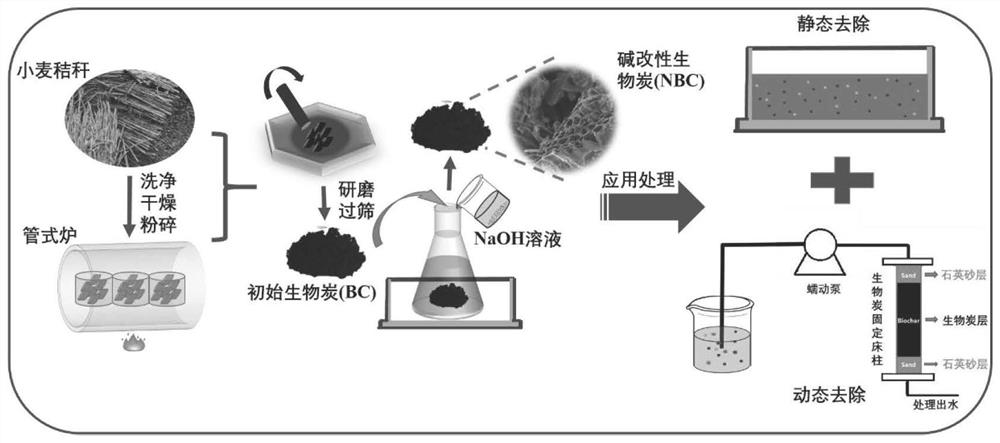

[0078] figure 1 It is a schematic flow chart of the preparation process of alkali-modified biochar and the removal of emerging pollutants in sewage by using alkali-modified biochar in the present invention. Such as figure 1 As shown, the initial biochar was prepared by pyrolysis carbonization method, the initial biochar was impregnated with alkaline solution to prepare alkali-modified biochar, and then put into the sewage containing emerging pollutants and fully contacted by shaking, or the emerging pollutants The mixed solution creeps through the fixed bed column filled with alkali-modified biochar, and the emerging pollutants in the above two methods will be adsorbed on the surface or pores of the biochar, achieving a good removal effect.

[0079] Among them, the pyrolysis operating conditions of the tube furnace are heating temperature of 700°C and heating time of 2 hours.

Embodiment 1

[0080] The preparation of embodiment 1 alkali-modified biochar

[0081] First, clean the collected wheat straw with ultrapure water, dry it in an oven at 80°C for 24 hours, cut the dry straw into small pieces of about 2 cm, put them in a quartz crucible, wrap them in aluminum foil, and place them in a tube furnace. Under the atmosphere, heat up to 700°C at a heating rate of 10°C / min, hold for 2h, then stop heating, and keep the nitrogen atmosphere until the tube furnace cools down to room temperature, turn off the nitrogen switch and the electric furnace power supply, take out the crucible and seal it for storage, and obtain the described initial biochar. Then the initial biochar was ground with an agate mortar and passed through a 120-mesh sieve to obtain initial biochar powder (BC). Weigh 5g of initial biochar powder into a 50mL Erlenmeyer flask, slowly add 50mL of 1mol / L sodium hydroxide solution along the wall to ensure that the mass-volume ratio of initial biochar powder...

Embodiment 2

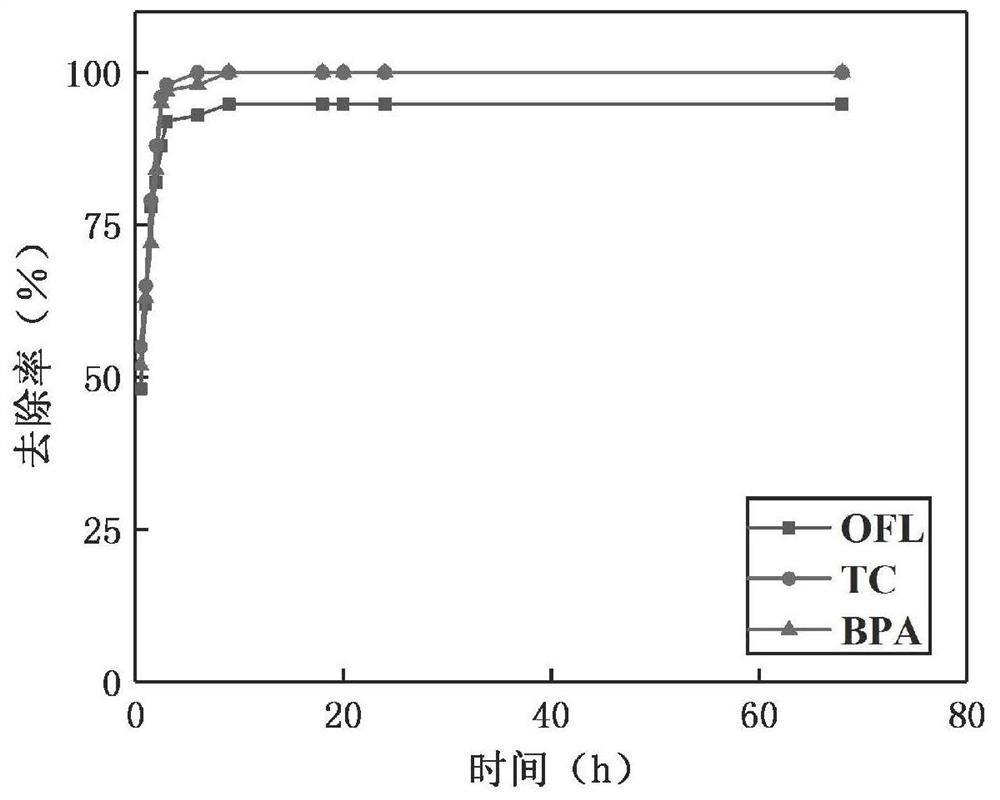

[0083] Embodiment 2 utilizes the static adsorption of alkali-modified biochar

[0084] In a 100mL glass bottle, the alkali-modified biochar NBC prepared in Example 1 of the present invention was put into sewage containing a single emerging pollutant (BPA, tetracycline TC, ofloxacin OFL, etc.). The specific implementation is to drop 200mg / L of alkali-modified biochar and 20mg / L of single pollutant into a glass bottle containing 50mL of sewage (to ensure that the mass ratio of alkali-modified biochar to emerging pollutants is 10:1), and then The glass bottle was placed in a shaker and oscillated at a speed of 180r / min for 70h to carry out the static removal experiment of pollutants.

[0085] image 3 is the effect of alkali-modified biochar on the removal of different emerging pollutants over time in the static adsorption method. It can be seen from the figure that the adsorption of NBC to OFL and BPA is rapidly saturated within 9 hours, and the adsorption to TC only reaches e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com