Preparation method of sodium sulfite

A technology of sodium sulfite and sodium bisulfite, applied in the field of industrial chemical industry, can solve the problems of high cost, easy to produce by-products, low purity of sodium sulfite, etc., and achieve the effect of ensuring absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

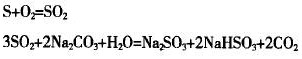

Method used

Image

Examples

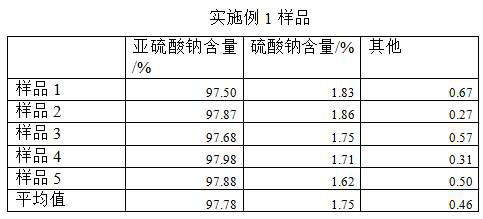

Embodiment 1

[0027] A preparation method of sodium sulfite, comprising the following steps:

[0028] (1) Use an absorption tower to collect flue gas from sulfuric acid production, and then fill the collected flue gas into sodium hydroxide solution to obtain the first mixed liquid. The temperature of the sodium hydroxide solution is 30°C, and the first mixed liquid The Ph value is 7.5, (the temperature of the sodium hydroxide solution is limited mainly to improve the dissolution rate of sulfur trioxide in sodium hydroxide. At room temperature, sulfur trioxide is liquid and sulfur dioxide is gaseous, so it can be guaranteed The sulfur trioxide contained in the sulfur dioxide is completely absorbed), the sodium hydroxide solution is to remove the iron oxide dust particles that may be contained in the flue gas, generate iron hydroxide precipitation, and at the same time make the sulfur dioxide and sulfur trioxide absorbed by the sodium hydroxide solution;

[0029] (2) Filter the first mixed li...

Embodiment 2

[0038] A preparation method of sodium sulfite, comprising the following steps:

[0039] (1) Use an absorption tower to collect flue gas from sulfuric acid production, and then fill the collected flue gas into sodium hydroxide solution to obtain the first mixed solution. The temperature of the sodium hydroxide solution is 35°C, and the first mixed solution The pH value is 9.5, and the sodium hydroxide solution is used to remove iron oxide dust particles that may be included in the flue gas, to form iron hydroxide precipitation, and to make sulfur dioxide and sulfur trioxide be absorbed by the sodium hydroxide solution;

[0040] (2) Filter the first mixed liquid, and obtain the second mixed liquid after solid-liquid separation;

[0041] (3) Put the second mixed solution into a reaction vessel with an air guide tube, then add sulfuric acid until no more gas is generated, and collect the sulfur dioxide gas generated by the reaction;

[0042] (3) Weighing the mass of the collected...

Embodiment 3

[0046] A preparation method of sodium sulfite, comprising the following steps:

[0047] (1) Use an absorption tower to collect flue gas from sulfuric acid production, and then fill the collected flue gas into sodium hydroxide solution to obtain the first mixed solution. The temperature of the sodium hydroxide solution is 32°C, and the first mixed solution Ph value is 8.5;

[0048] (2) Filter the first mixed liquid, and obtain the second mixed liquid after solid-liquid separation;

[0049] (3) Put the second mixed solution into a reaction vessel with an air guide tube, then add sulfuric acid until no more gas is generated, and collect the sulfur dioxide gas generated by the reaction;

[0050] (3) Weighing the mass of the collected sulfur dioxide, washing the sulfur dioxide into the first sodium carbonate solution to obtain a sodium bisulfite solution;

[0051] (4) add the second sodium carbonate solution in the sodium bisulfite solution described in step (3), obtain sodium su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com