Ibuprofen-loaded o-vanillin composite particles and preparation method thereof

A technology of composite particles and o-vanillin, applied in the field of composites, can solve problems such as unfavorable industrial production application, unfavorable industrial production application, use of many auxiliary materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) At 40°C, prepare a mixed aqueous solution containing 0.01g / mL ibuprofen and 0.02g / mL o-vanillin;

[0038] (2) Stir the mixed solution in (1) until liquid-liquid phase separation occurs and the ibuprofen-o-vanillin oil droplets are evenly distributed in the water;

[0039] (3) Keep stirring to cool the solution to 1°C at a cooling rate of 30°C / 10min, and keep stirring at 0.226kW / m 3 until crystallization;

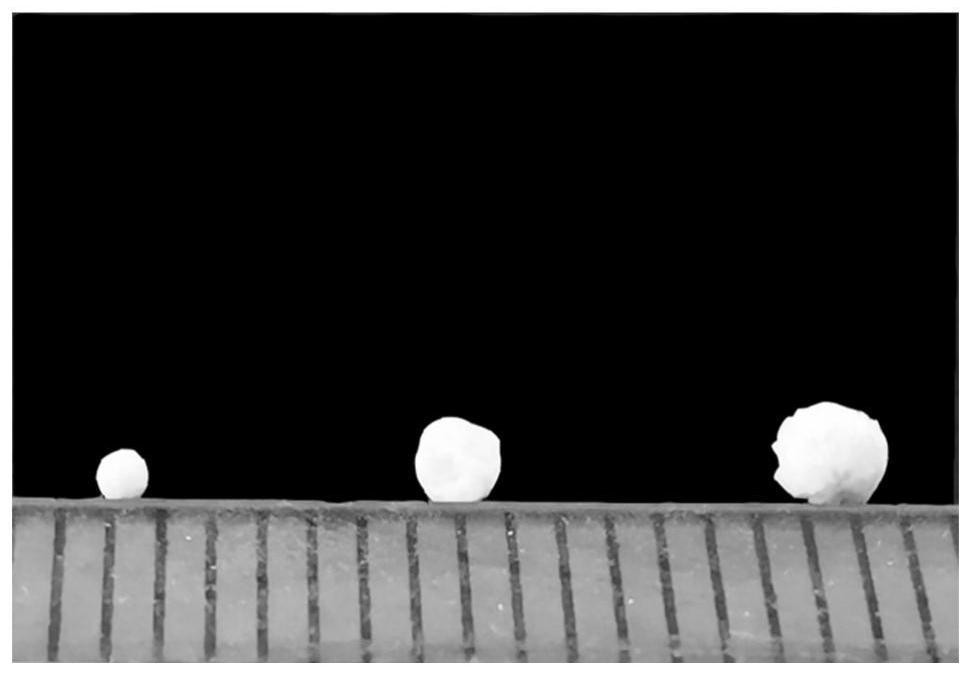

[0040] (4) adding a mass fraction of 0.02% surfactant sodium stearate, and continuously stirring for 0.5h, the crystals are coalesced into compact spheres;

[0041] (5) After vacuum filtration, washing with water, and drying at normal pressure at 15° C. for 12 hours, the ibuprofen-loaded o-vanillin functional granules were obtained.

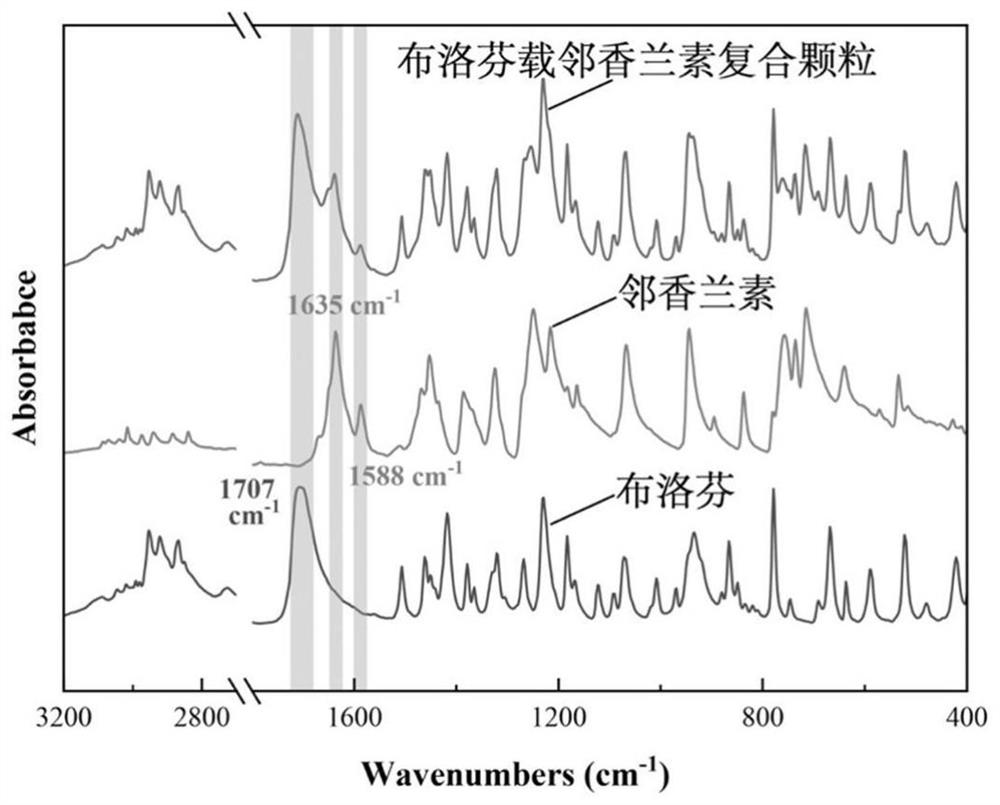

[0042] The solid infrared absorption spectrum of product (instrument model ALPHA, Bruker, Germany) sees figure 1 , the infrared spectrum of the product is at 1707cm -1 The absorption peak of ibuprofen appears at 1635, 1688cm -1 ...

Embodiment 2

[0045] (1) At 60°C, prepare a mixed aqueous solution containing 0.08g / mL ibuprofen and 0.12g / mL o-vanillin;

[0046] (2) Stir the mixed solution in (1) until liquid-liquid phase separation occurs and the ibuprofen-o-vanillin oil droplets are evenly distributed in the water;

[0047] (3) Keep stirring to cool the solution to 5°C at a cooling rate of 45°C / 10min, and keep stirring at 0.489kW / m 3 until crystallization;

[0048] (4) adding the surfactant sodium hexametaphosphate with a mass fraction of 0.10%, and continuously stirring for 1.5 hours, so that the crystals are coalesced into compact spheres;

[0049] (5) After vacuum filtration, washing with water, and drying at normal pressure at 15° C. for 24 hours, the ibuprofen-loaded o-vanillin functional granules were obtained.

[0050] According to the solid infrared absorption spectrum result of product (test method is the same as embodiment 1), it is judged that product is the physical mixture of ibuprofen and o-vanillin, a...

Embodiment 3

[0052] (1) At 70°C, prepare a mixed aqueous solution containing 0.15 g / mL ibuprofen and 0.10 g / mL o-vanillin;

[0053] (2) Stir the mixed solution in (1) until liquid-liquid phase separation occurs and the ibuprofen-o-vanillin oil droplets are evenly distributed in the water;

[0054] (3) Keep stirring to cool the solution to 7°C at a cooling rate of 60°C / 10min, and keep stirring at 1.479kW / m 3 until crystallization;

[0055] (4) adding a surfactant sodium dodecylbenzenesulfonate with a mass fraction of 0.30%, and stirring continuously for 3.5 hours, so that the crystals are coalesced into compact spheres;

[0056] (5) After vacuum filtration, washing with water, and drying at normal pressure at 20° C. for 36 hours, the ibuprofen-loaded o-vanillin functional granules were obtained.

[0057] According to the solid infrared absorption spectrum result of product (test method is the same as embodiment 1), it is judged that product is the physical mixture of ibuprofen and o-vanil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com