Compound microbial agent for sewage treatment and preparation method and application thereof

A compound microbial inoculum and sewage treatment technology, applied in microorganism-based methods, biochemical equipment and methods, biological water/sewage treatment, etc. and other problems, to achieve the effect of long survival time, improving growth and reproduction environment, and reducing BOD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

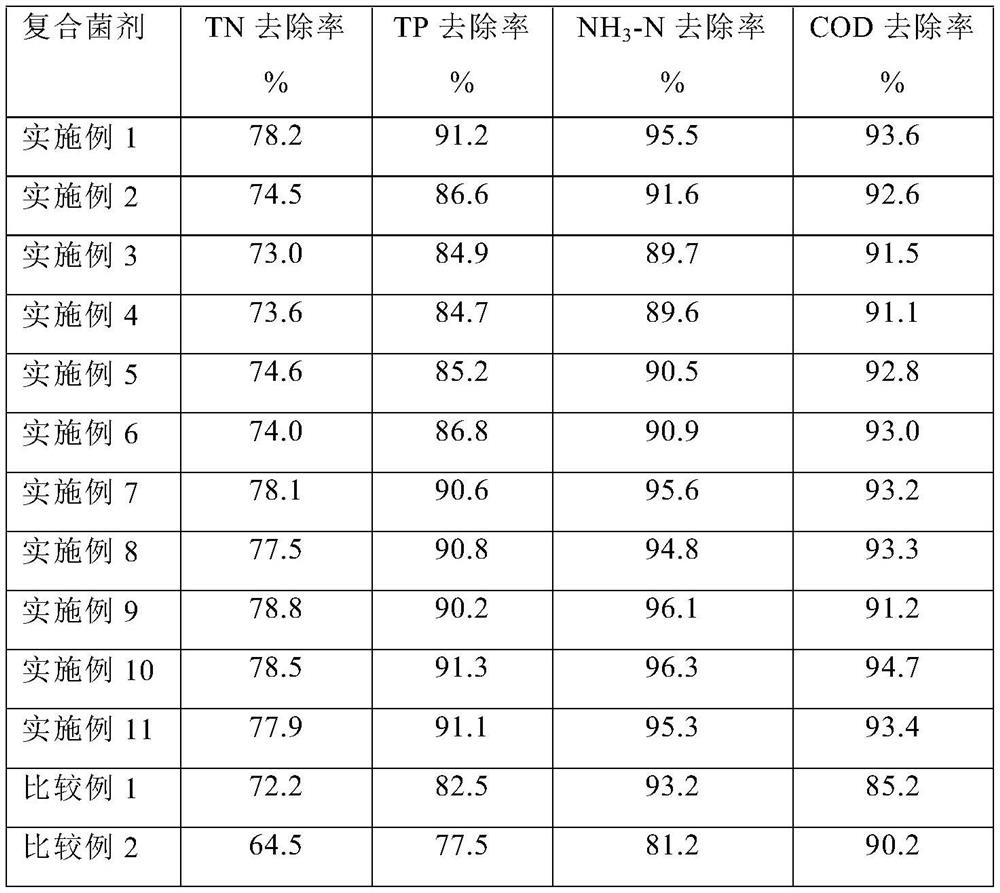

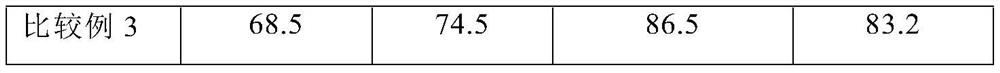

Examples

preparation example Construction

[0052] (1) Preparation of composite microbial agent

[0053] 1. Prepare culture medium

[0054] 1.1. Seed medium: 1% peptone, 0.5% yeast extract, 1% sodium chloride, natural pH;

[0055] 1.2. Basic fermentation medium: soybean cake powder 5%, corn starch 4%, ammonium sulfate 0.6%, K 2 HPO 4 1%, MgSO 4 ·7H 2 O 0.075%, NaCl 1.0%, pH7.8;

[0056] 2. Activation of strains: transfer the preserved strains to the slant medium for cultivation, and prepare them for later use;

[0057] 3. Preparation of seed solution

[0058] Take a ring of activated bacteria and insert it into a 250ml Erlenmeyer flask with a capacity of 50ml seed medium, at 37°C

[0059] Cultivate at 180r / min for 18h;

[0060] 4. Shake flask culture

[0061] Take 1ml of seed liquid respectively, put it into a 250ml Erlenmeyer flask filled with 50ml of fermentation medium, shake and cultivate at 30°C for 12h, and the rotation speed is 160r / min;

[0062] 5. Fermentation conditions

[0063] Use shake flasks to...

Embodiment 1

[0076] 1. Fermentation culture of each bacteria: Introduce the slant strains of Bacillus subtilis, Bacillus licheniformis, Bacillus amyloliquefaciens, Bacillus lateralis and Thiobacillus denitrificans into LB liquid medium respectively, and culture them at 37°C; Insert the slant strain of Streptomyces griseus into the fermentation medium (soy bean cake powder 5%, cornstarch 4%, ammonium sulfate 0.6%, K 2 HPO 4 1%, MgSO 4 ·7H 2 O 0.075%, NaCl 1.0%, pH7.8 (with reference to Li Haiyan et al., Science and Technology and Engineering, 2013, 13 (27), 8202-8204)), 32 ℃ culture, until each bacteria in the liquid fermentation broth Bacteria concentrations were not less than 1×10 9 CFU / ml, freeze-dried to obtain dry bacteria powder in a dormant state.

[0077] 2. Preparation of modified highland barley stalk powder: take the highland barley stalk that has been dried and crushed and sieved through a 100-mesh sieve, add ammonia water with a concentration 14% (mass fraction) of 10 time...

Embodiment 2

[0081] In the same manner as in Example 1, dry powders of various bacteria in a dormant state were prepared, and the components were mixed according to the following ratios to obtain a composite microbial bacterial agent.

[0082] 15 parts of Bacillus subtilis, 15 parts of Bacillus licheniformis, 15 parts of Bacillus amyloliquefaciens, 15 parts of Bacillus lateralis, 13 parts of Streptomyces griseus, 8 parts of Thiobacillus denitrification, 75 parts of starch, 75 parts of modified highland barley straw powder .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com