Polysulfone and preparation method thereof

A technology of polysulfone and cross-linked polystyrene, applied in the field of polysulfone and its preparation, a method and the polysulfone obtained therefrom, can solve the problem that the catalyst cannot be recycled, etc., to increase market competitiveness and appearance Excellent, catalytic activity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

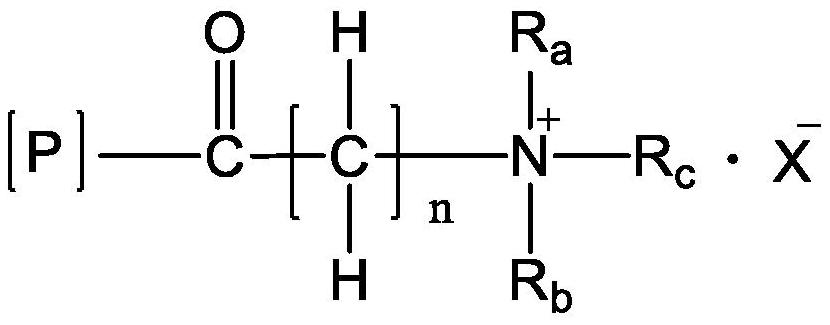

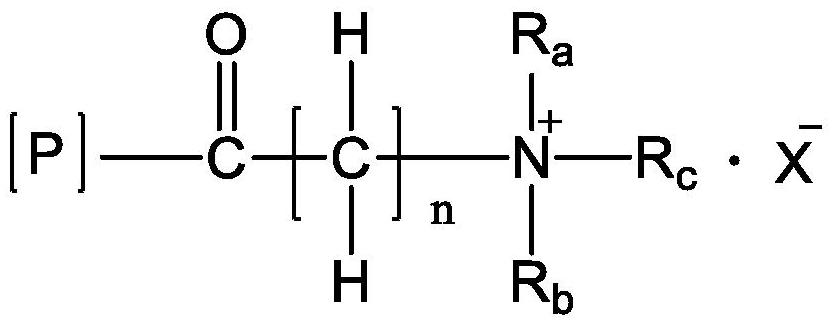

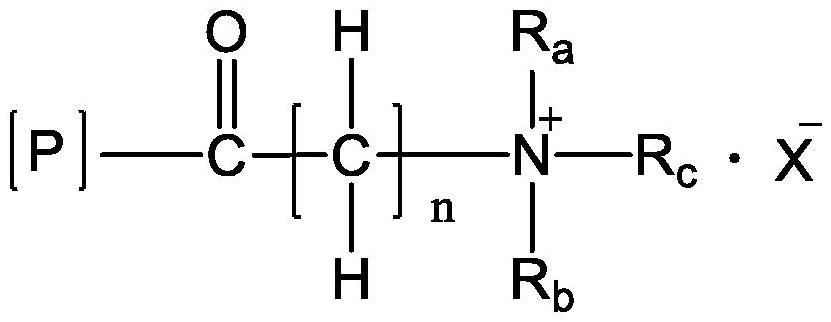

Image

Examples

Embodiment 1

[0043] Put 0.05mol cross-linked polystyrene microspheres (PSD10000-L5, Suzhou Zhiwei Nano Technology Co., Ltd.) mol chloroacetyl chloride, blow nitrogen, slowly add 0.075mol anhydrous aluminum trichloride, react at room temperature for 4h. After the reaction is finished, the product mixture is treated with 1 mol / L dilute hydrochloric acid, the product is washed with distilled water until the washing liquid does not contain chloride ions, and after vacuum drying, chloroacetyl cross-linked polystyrene microspheres are obtained. The content of chloroacetyl group is 3.51mmol / g as determined by oxygen nitrogen combustion-Volhard method.

[0044] In a four-necked flask equipped with a stirrer, a reflux condenser and a thermometer, add 4.02g of chloroacetyl crosslinked polystyrene (chloroacetyl content: 14.1mmol), 50mL of N,N-dimethylformamide, and swell After 12 hours, add 28.2 mmol of triethylamine, and stir the reaction at 80°C for 24 hours. After the reaction, wash the product m...

Embodiment 2

[0047] The preparation process of the cross-linked polystyrene immobilized tributylmethyl ammonium chloride with propionyl spacer is the same as in Example 1, except that 28.2mmol tributylamine is used instead of triethylamine as a quaternization reagent, which is determined by elemental analysis , the bonding amount of the quaternary ammonium group was 3.16 mmol / g.

[0048] In a four-necked reaction flask with oil bath heating, stirrer, water separator and condenser, add 0.1mol bisphenol S, 0.1mol sodium carbonate, 0.098mol 4,4'-dichloro Diphenyl sulfone, 0.32g cross-linked polystyrene immobilized tributylmethylammonium chloride (quaternary ammonium group content 1mmol), 409.68g N,N-dimethylformamide, stirring nitrogen for 0.5h, the oil bath The temperature was raised to 170°C (system temperature 153°C), 125g of N,N-dimethylformamide was distilled off, and the reaction was continued for 3h to obtain a yellow viscous polysulfone solution. Methyl chloride gas (gas flow rate: 1...

Embodiment 3

[0050] The preparation process of the cross-linked polystyrene immobilized dodecyltrimethylammonium chloride with valeryl spacer arm is the same as that of Example 1, except that 28.2 mmol of dodecyldimethylamine is used as the quaternizing agent, The bonding amount of the quaternary ammonium group was determined to be 3.3 mmol / g by elemental analysis.

[0051] 1mol bisphenol A, 2mol potassium carbonate, 0.95mol 4,4'-dichlorodiphenyl sulfone, 30.3g cross-linked polystyrene immobilized dodecyltrimethylammonium chloride (quaternary ammonium group content 0.1mol ), 0.98kg sulfolane, put into the reaction kettle with temperature control, stirring and reflux water separation device at one time, nitrogen purging for 0.5h, the temperature of the reaction kettle was raised to 300°C (system temperature 285°C), and 120g of sulfolane was evaporated , Continue to react for 10h to obtain yellow viscous polysulfone solution. Methyl chloride gas (gas flow rate: 1 L / min) was introduced into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com