Bifunctional electrode for alkaline water electrolysis, and preparation method and application thereof

A water electrolysis and electrode technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of alloy composition change, catalyst catalytic activity attenuation, etc., and achieve the effect of fast reaction speed, improved stability, and high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

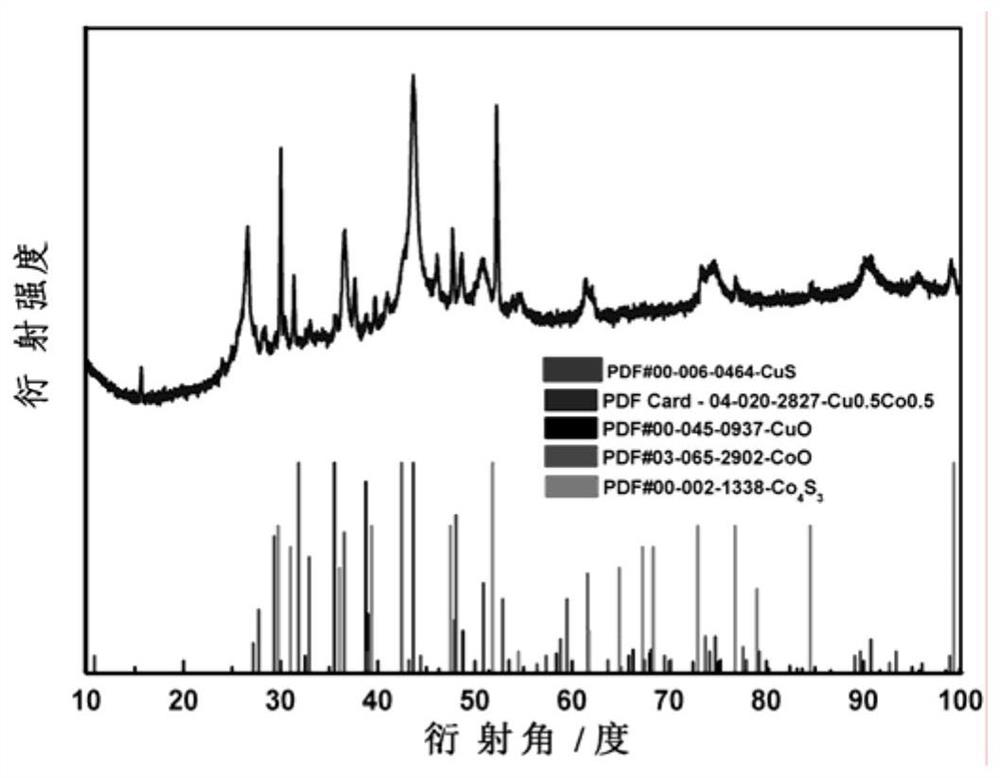

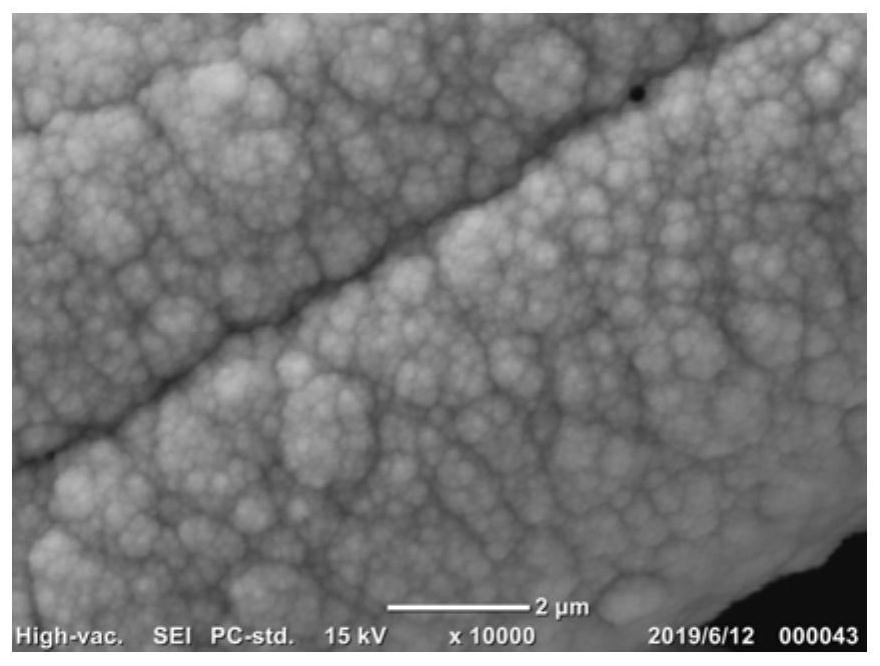

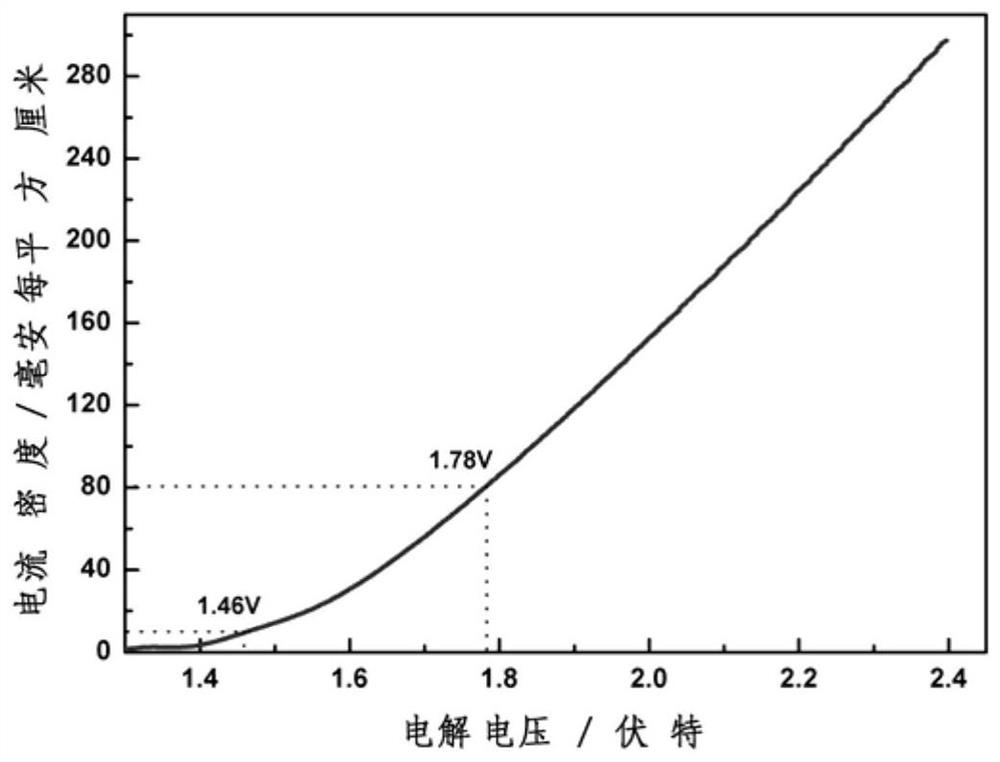

Image

Examples

Embodiment 1

[0042] 1. Electrode material pretreatment: Cu content ≥ 99.9%, porosity 90%, thickness 1mm, geometric area 6cm 2 Two pieces of foamed copper are used as the base material. First, soak them in acetone at room temperature for 15 minutes to remove the surface grease; finally, soak them in concentrated hydrochloric acid for 15 minutes to remove the surface scale, and then rinse them with a large amount of deionized water. To neutral, dry with high-purity Ar gas;

[0043] 2. Electroplating solution preparation: to analyze pure grade CoSO 4 ·7H 2 O and CuSO 4 ·5H 2 O as Co salt and Cu salt, H 3 BO 3 As a pH stabilizer, sodium citrate as a complexing agent, PEG with a relative molecular weight of 6000 as an additive, and 200ml of electroplating solution prepared with ultra-pure water with a resistivity of 18.2MΩ to control the CoSO 4 ·7H 2 O, CuSO 4 ·5H 2 O, H 3 BO 3 The concentrations of , sodium citrate and PEG are 0.03M, 0.03M, 0.3M, 0.06M and 100ppm respectively. After...

Embodiment 2

[0051] 1. Electrode material pretreatment: The porosity produced by Toray Corporation of Japan is 90%, the thickness is 0.2mm, and the geometric area is 6cm 2 Two pieces of TGP-060 carbon paper are used as the base material. First, soak the two pieces in acetone at room temperature for 15 minutes to remove surface grease, then wash them with a large amount of deionized water until neutral, and dry them with high-purity Ar gas;

[0052] 2. Electroplating solution preparation: to analyze pure grade CoSO 4 ·7H 2 O and NiSO 4 ·6H 2 O is used as Co salt and Ni salt, ammonium sulfate is used as pH stabilizer, EDTA disodium salt is used as complexing agent, PVP K-30 with a relative molecular weight of 55,000 is used as an additive, and 200ml of electroplating is prepared with ultrapure water with a resistivity of 18.2MΩ solution, to control the CoSO in the bath 4 ·7H 2 O, NiSO 4 ·6H 2 O, (NH 4 ) 2 SO 4 , EDTA disodium salt and PVP concentrations are 0.083M, 0.017M, 1M, 0.4M...

Embodiment 3

[0060] 1. Electrode material pretreatment: Ni content ≥ 99.7%, porosity 70%, thickness 3mm, geometric area 6cm 2 Two pieces of nickel foam are used as the base material. First, soak them in acetone at room temperature for 15 minutes to remove surface grease; finally, immerse them in 1M hydrochloric acid for 15 minutes to remove surface scale, and then rinse with a large amount of deionized water. To neutral, dry with high-purity Ar gas;

[0061] 2. Preparation of electroplating solution: to analyze pure NiCl 2 ·6H 2 O and FeCl 2 4H 2 O as Ni salt and Fe salt, H 3 BO 3 As a pH stabilizer, citric acid as a complexing agent, PEG with a relative molecular weight of 8000 as an additive, and 200ml of electroplating solution prepared with ultra-pure water with a resistivity of 18.2MΩ to control the NiSO 2 ·6H 2 O, FeCl 2 4H 2 O, H 3 BO 3 The concentrations of citric acid, PEG and PEG were 2.5mM, 7.5mM, 0.02M, 0.2M and 60ppm respectively. After the components were completel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com