Method for preparing high-purity silicon by recovering silicon wafer cutting waste

A technology for silicon wafer cutting and waste recycling, applied in chemical instruments and methods, silicon compounds, waste treatment, etc., can solve the problems of low impurity removal rate and serious secondary oxidation, so as to overcome secondary oxidation, improve recovery rate, The effect of reducing energy consumption in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

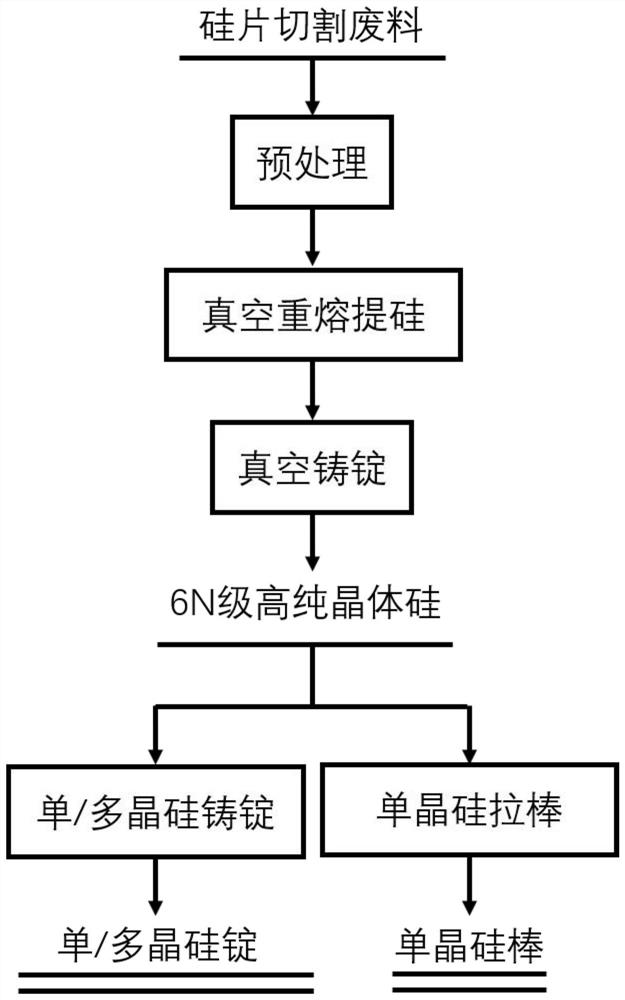

[0030] Example 1: A method of preparing high purity silicon in a wafer cutting waste (see figure 1 ),Specific steps are as follows:

[0031] (1) Put the fresh silicon sliced waste slurry of a single crystal silicon slice enterprise in Yunnan, a vacuum dry dehydration to constant weight to obtain a silicon cutting waste, wherein the vacuum drying temperature is 60-80 ° C, and the vacuum pressure of vacuum drying is not higher than the vacuum drying temperature. -0.6bar, the impurity content in silicon cutting waste is Al 53 ppmw, Fe 300 ppmw, Ni 51PPMW, Ti 80.5 ppmw, Ca 50 ppmw, mg15ppmw, b 5.4 ppmw, p 10 ppmw, total impurity content of 564.9 ppmw;

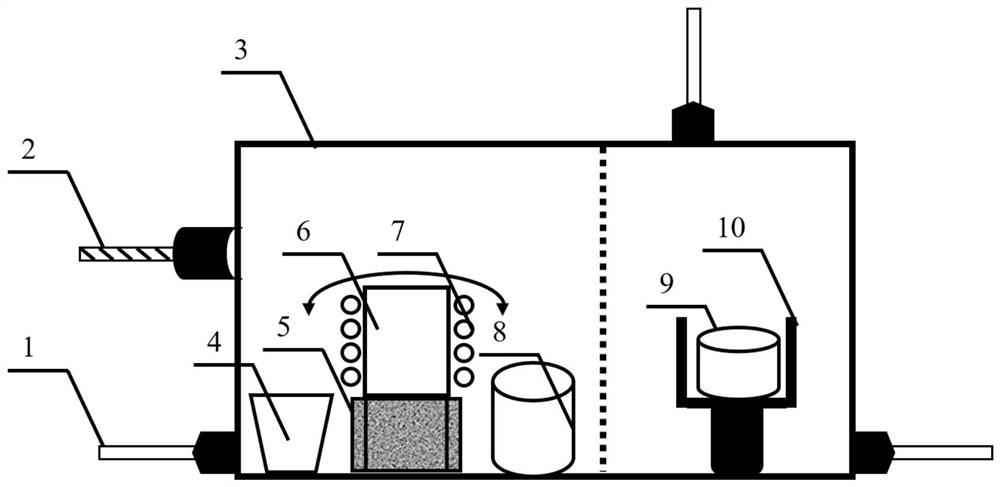

[0032] (2) Transfer the wafer cutting waste to the graphite crucible and compact, put the graphite 坩 坩 感 感 感 感 感 加 定 定 定 定 定 定 处理 定 定 定 定 处理 处理 定 定 定 定 放 放After the furnace is lower than 50Pa, the heating is turned on, and the temperature rise time is about 0.5 h, so that the wafer cuts the waste, heat-insulation refining under vacuu...

Embodiment 2

[0035] Example 2: Method for preparing high purity silicon by silicon cutting waste recovery (see figure 1 ),Specific steps are as follows:

[0036] (1) After the wafer cutting, settling, pressure filtering, and flame retardant liquid, the silicon plate cutting waste slurry is directly separated, wherein the wet treatment process is vacuum. The two glyphs were acidic under conditions, of which one acidic leach was 2 m HCl + 2.5 M HF mixed acid, the leaching temperature was 60 ° C, the leaching time was 3 h, and the solid-liquid separation was performed after the leaching, and then the segment leaching was carried out. 4M HCl, the leaching temperature is 60 ° C, the leaching time is 3 h, and the second-stage leaching is faster under vacuum conditions, dehydrated and dried. After two segments, the average content of the aburmented wafer cutting waste after the two sections is Al 61.5 ppmw, Fe 38.5PPMW, Ni 46.5 ppmw, Ti 4.8ppmw, Ca 18ppmw, Mg5PPMW, B 5PPMW, P10 PPMW, total impurity c...

Embodiment 3

[0040] Example 3: Method for preparing high purity silicon by wafer cutting waste (see figure 1 ),Specific steps are as follows:

[0041] (1) Cut the silicon wafer of a single crystal silicon slice enterprise in Yunnan to dehydrate to constant weight, wherein the vacuum drying temperature is 60-80 ° C, and the vacuum pressure of vacuum drying is not higher than -0.6 bar, wafer cutting waste. The impurity content is AL53PPMW, Fe 300 ppmw, Ni 51PPMW, Ti 80.5 ppmw Ca 50 ppmw mg 15 ppmw, b 5.4 ppmw, p10 ppmw, total impurity content of 564.9 ppmw;

[0042] (2) Transfer the wafer cutting waste to the graphite crucible and compact, put the graphite 坩 坩 感 感 感 感 感 加 定 定 定 定 定 定 处理 定 定 定 定 处理 处理 定 定 定 定 放 放After the furnace is below 50Pa, the heating is turned on, and the temperature rise is about 0.5 h to cut the wafer cutting waste, and the refined refining is insulated under vacuum, temperature 1550-1600 ° C. After the insulation, the furnace is cooled.

[0043] (3) Cut the silicon ingot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com