Preparation method of low-temperature solid electrolyte and application of low-temperature solid electrolyte in low-temperature solid supercapacitor

A solid-state electrolyte and supercapacitor technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrolytes, etc., can solve the problems of poor performance, decreased electrolyte conductivity, high freezing point of organic solvents, low explosion hazard, and improved voltage window. , the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Low Temperature Solid Electrolyte Membrane:

[0038] Step S1: Add 16ml of acetone to 2.4g of polyvinylidene fluoride-hexafluoropropylene PVDF-HFP particles, and fully dissolve it with magnetic stirring at 50°C to obtain a transparent viscous solution A;

[0039] Step S2: Mix 6ml of propylene carbonate, 12ml of acetonitrile and 12ml of methyl formate, add 6g of 1-ethyl-3-methylimidazolium tetrafluoroborate, and stir evenly at room temperature with magnetic force to obtain a clear and transparent solution B;

[0040] Step S3: Add 16ml of solution B obtained in step S2 to 16ml of solution A obtained in step S1, and mix well to obtain precursor solution C;

[0041] Step S4: coating the precursor solution C obtained in step S3 on a clean and smooth substrate, and drying naturally for 24 hours to obtain a low-temperature solid electrolyte membrane with a thickness of 20-100 um.

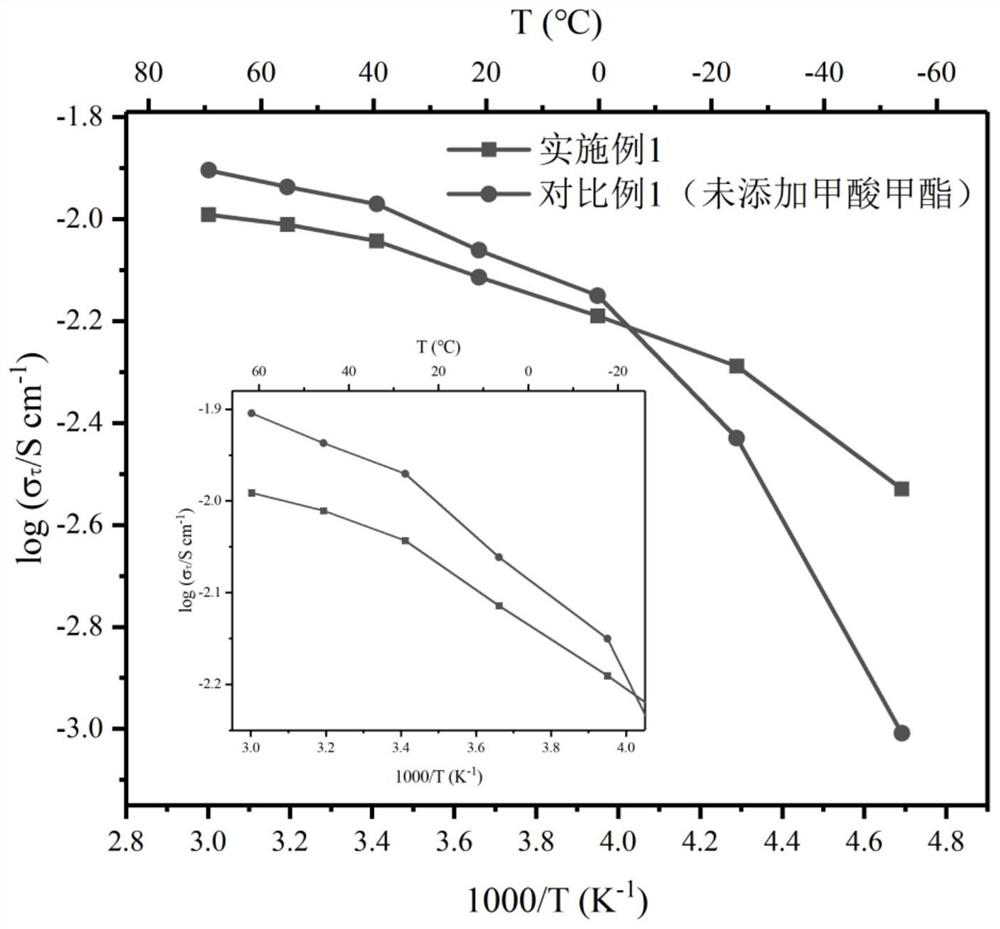

[0042] figure 1 The ionic conductivity figure of the solid electrolyte membrane ...

Embodiment 2

[0049] This embodiment uses solution A with different mass fractions.

[0050] Preparation of Low Temperature Solid Electrolyte Membrane:

[0051] Step S1: Add 24ml of acetone to 2.4g of polyvinylidene fluoride-hexafluoropropylene PVDF-HFP particles, and fully dissolve it with magnetic stirring at 50°C to obtain a transparent viscous solution A;

[0052] Step S2: Mix 6ml of propylene carbonate, 12ml of acetonitrile and 12ml of methyl formate, add 6g of 1-ethyl-3-methylimidazolium tetrafluoroborate, and stir evenly at room temperature with magnetic force to obtain a clear and transparent solution B;

[0053] Step S3: Add 16ml of solution B obtained in step S2 to 16ml of solution A obtained in step S1, and mix well to obtain precursor solution C;

[0054] Step S4: coating the precursor solution C obtained in step S3 on a clean and smooth substrate, and drying naturally for 24 hours to obtain a low-temperature solid electrolyte membrane with a thickness of 20-100 um.

[0055] T...

Embodiment 3

[0058] The present embodiment adopts different ratios of solvents propylene carbonate, acetonitrile, and methyl formate.

[0059] Preparation of Low Temperature Solid Electrolyte Membrane:

[0060] Step S1: Add 16ml of acetone to 2.4g of polyvinylidene fluoride-hexafluoropropylene PVDF-HFP particles, and fully dissolve it with magnetic stirring at 50°C to obtain a transparent viscous solution A;

[0061] Step S2: Mix 6ml of propylene carbonate, 6ml of acetonitrile and 6ml of methyl formate, add 3.6g of 1-ethyl-3-methylimidazolium tetrafluoroborate, and stir evenly at room temperature to obtain a clear and transparent solution B;

[0062] Step S3: Add 16ml of solution B obtained in step S2 to 16ml of solution A obtained in step S1, and mix well to obtain precursor solution C;

[0063] Step S4: coating the precursor solution C obtained in step S3 on a clean and smooth substrate, and drying naturally for 24 hours to obtain a low-temperature solid electrolyte membrane with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com