Poly (naphthalene diimide ketone) linear polycondensate photocatalyst as well as preparation method, acidification treatment method and application of poly (naphthalene diimide ketone) linear polycondensate photocatalyst

A technology of polynaphthalene diimide ketone and photocatalyst, which is applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, chemical instrument and method, etc., and can solve the problem of low utilization rate of sunlight , the effect is not very ideal, etc., to achieve the effect of improving photocatalytic efficiency, good market application prospects, and wide spectral response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

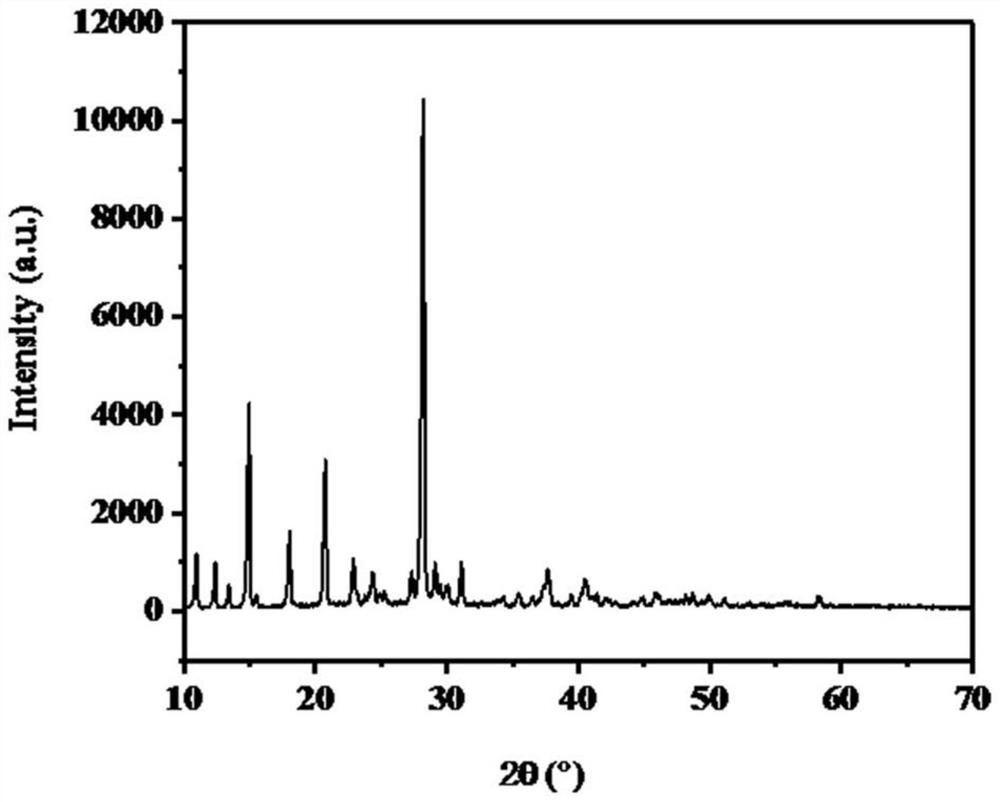

[0023] A polynaphthalene diimide ketone linear condensation polymer photocatalyst, its monomer contains naphthalene diimide and ketone structure, its general structural formula is shown in the following formula I:

[0024]

[0025] The concrete steps of its synthetic scheme are as follows:

[0026] Add urea (0.12g, 2.0mmol), 1,4,5,8-naphthalene tetracarboxylic dianhydride (0.54g, 2.0mmol), zinc acetate (0.37g, 2.0mmol), 5.0g imidazole in a 500mL single-necked flask (solvent), react at 140°C for 5 hours under high temperature and argon protection, add 250mL hydrochloric acid (1mol / L) after the reaction is cooled to room temperature, stir and mix until there is no further precipitation, then vacuum filter the reaction system and wash the precipitate with distilled water until Free of chloride ions, then dry in a vacuum oven, and finally wash with dimethyl sulfoxide until the solution is colorless, and collect 0.47 g of a tan solid, which is the polynaphthalene diimide ketone ...

Embodiment 2

[0029] A kind of acidification treatment scheme of polynaphthalimide ketone linear condensation polymer photocatalyst, concrete steps are as follows:

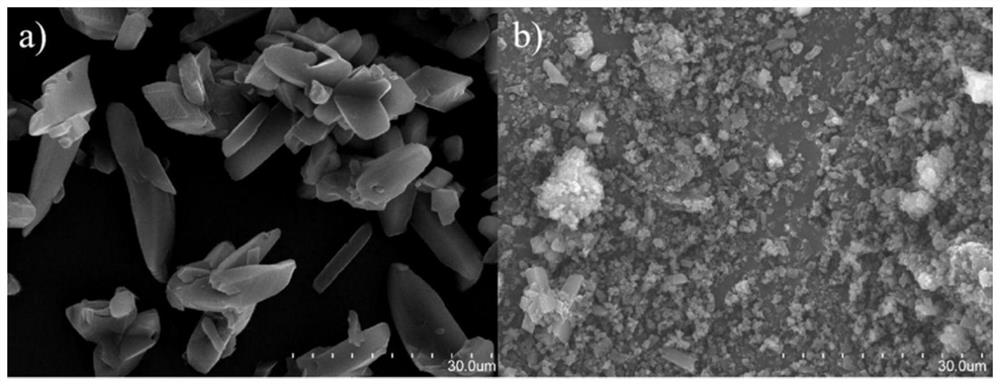

[0030] Weigh 0.1g polynaphthalene diimide ketone linear condensation polymer photocatalyst (Urea-NDI) to a 200mL beaker, add 10mL 98% concentrated sulfuric acid to it, and perform ultrasonication for 5min, then add 150mL of deionized water to it After the insoluble precipitate was formed, it was left to stand for 30 minutes, and then filtered and dried. The obtained mud white solid was acidified polynaphthalene diimide ketone linear polycondensate (Urea-NDI-AT). The scanning electron microscope pictures before and after acidification treatment are as follows: figure 2 shown by figure 2 (a) to figure 2 It can be seen from the change of (b) that the polynaphthalimide ketone linear condensation polymer photocatalyst after acidification has a smaller volume series, more nanometerization, and an increased specific surface area....

Embodiment 3

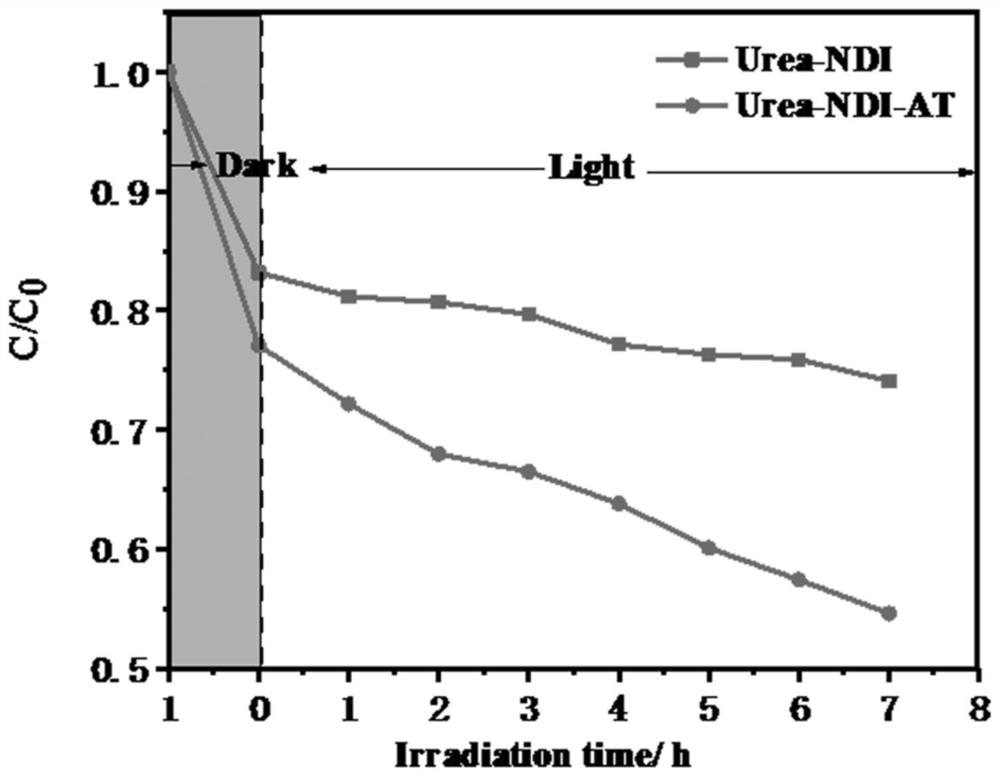

[0032] A polynaphthalimide ketone linear condensation polymer photocatalyst for the degradation of rhodamine B scheme, the specific steps are as follows:

[0033] (1) Add the polynaphthalimide ketone linear condensation polymer photocatalyst that 10mg embodiment 1 makes in the photoreaction bottle that fills rhodamine B solution, place the photoreaction bottle in a dark place, open the cycle condensation simultaneously Water, kept at room temperature, kept under stirring for 60 minutes, then sampled and centrifuged, then turned on the light source for photocatalytic degradation, and turned on the photochemical reactor for timing, taking a solution every 1h for centrifuged sampling.

[0034] (2) Take another optical reaction bottle and add 10 mg of Urea-NDI-AT prepared in Example 2 to it, and repeat the operation of (1).

[0035] (3) Preparation of standard song solution: Take five 100mL volumetric flasks numbered 1-5, add 20mL, 40mL, 60mL, 80mL, and 100mL of rhodamine B soluti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap