Algal toxin degrading enzyme as well as composite material and application

A technology of algae toxin-degrading enzymes and composite materials, which is applied in the fields of algae toxin-degrading enzymes and composite materials and applications, can solve the problems of low efficiency of immobilized enzymes, and achieve the effects of reducing production costs, eliminating toxicity, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

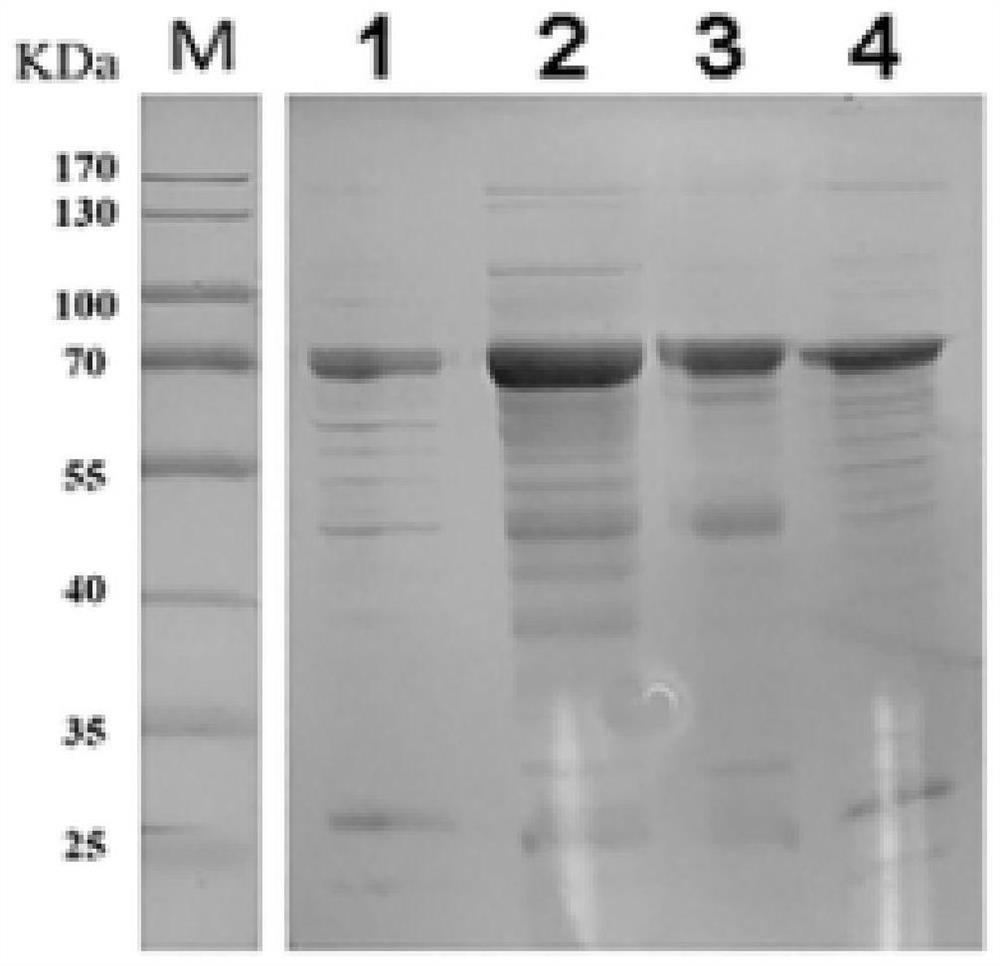

[0044] The method for preparing algae toxin-degrading enzyme provided by the invention comprises: cultivating the expression strain provided by the invention, inducing the expression of a gene encoding algae toxin-degrading enzyme; separating and purifying the expressed algae toxin-degrading enzyme. Described culture condition is routine culture condition, as using LB culture medium (solvent is water, solute and final concentration thereof are respectively: Tryptone 10g / L, yeast extract 5g / L, NaCl 10g / L), at 20-25 Cultivate at ℃ for 8-10h. Since the expression strain provided by the present invention contains the gene encoding the algal toxin degrading enzyme, it can efficiently express the algal toxin degrading enzyme. After culturing, the algae toxin degrading enzyme can be obtained through separation and purification. Methods known to those skilled in the art can be used to separate and purify (such as, high-speed refrigerated centrifugation induced culture fluid to collec...

Embodiment 1

[0054] This example is used to illustrate the preparation of the phycotoxin-degrading enzyme gene sequence, the construction of the vector, the preparation of the enzyme and the determination of the enzyme activity of the present invention.

[0055] (1) Acquisition of algae toxin-degrading enzyme coding gene and construction of expression vector

[0056] The gene sequence encoding algae toxin degrading enzyme wild-type MlrA and its mutants H6MA, MH6A and MAH6, the nucleotide sequences shown in SEQ ID NO: 5, SEQ ID NO: 6, SEQ ID NO: 7 and SEQ ID NO: 8 (The corresponding amino acid sequences are respectively SEQ ID NO: 1, SEQ ID NO: 2, SEQ ID NO: 3 and SEQ ID NO: 4) by artificial chemical synthesis, and then loaded into the pMAL-C2X plasmid to obtain algae toxin degrading enzyme The expression vector (entrusted to Beijing Qingke Biotechnology Co., Ltd. Wuhan Branch to complete).

[0057] (2) Obtaining of expression strain and preparation of algae toxin degrading enzyme

[0058...

Embodiment 2

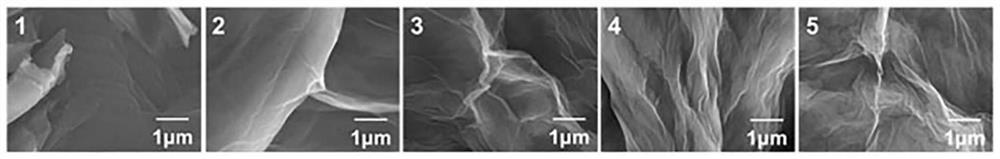

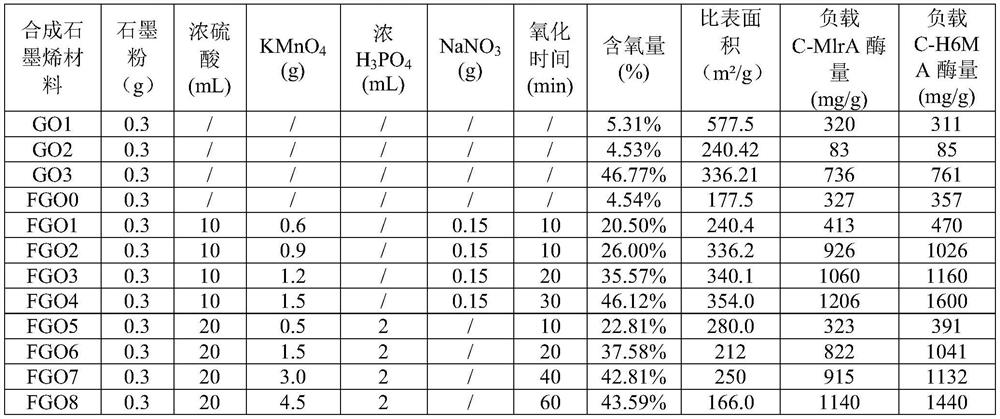

[0068] This embodiment is used to illustrate the preparation method of the oxygen-rich graphene material FGOs of high-efficiency immobilized algal toxin degrading enzyme, and its specific preparation steps are as follows:

[0069] 1. Weigh 0.1-0.5g graphite powder, add strong acid (concentrated sulfuric acid, concentration is 98% by weight) and additive (NaNO 3 or concentrated H 3 PO 4 (concentration is 85.8% by weight)), slowly add strong oxidant (potassium permanganate) of different quality under ice-water bath, be heated to about 40 ℃, stirring oxidation 10-60 minute (concrete addition amount and time are as shown in table 1) .

[0070] Table 1 The characteristic parameters and maximum loading enzyme amount of FGOs synthesized under different conditions

[0071]

[0072] In Table 1, GO1-GO3 are different commercial graphene oxides, respectively purchased from Suzhou Crystal Silicon Electronic Technology Co., Ltd., China; FGO0 is the raw material for preparing oxygen-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com