Sodium-lithium-iron-manganese-based layered oxide material, and preparation method and application thereof

An oxide, layered technology for applications in materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

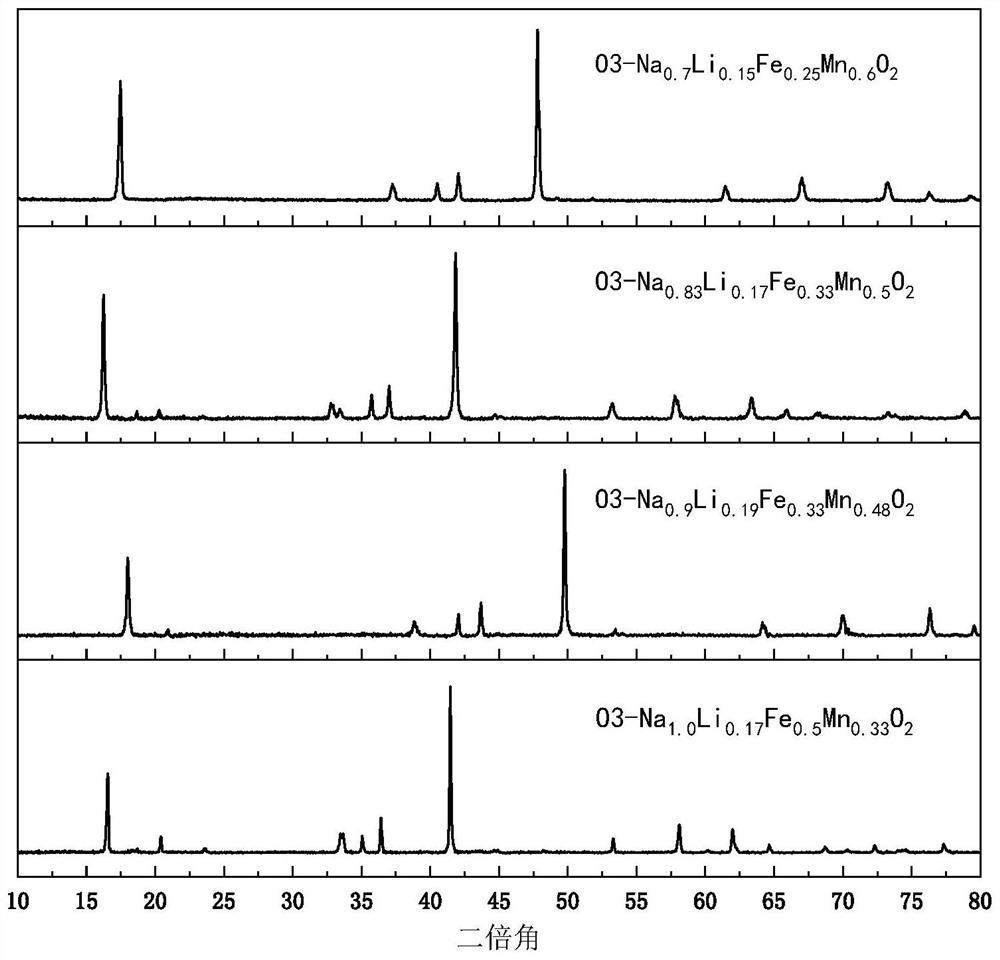

[0062] The embodiment of the present invention provides a sodium-lithium-iron-manganese-based layered oxide material with oxygen ion valence, its preparation method and application. The layered oxide material is easy to prepare, and the contained elements sodium, lithium, iron and manganese are all non-toxic and safe elements, and are abundant in the earth's crust, so the manufacturing cost is low. The sodium-ion secondary battery using the sodium-lithium-iron-manganese-based layered oxide material of the present invention is simple to prepare, and it is found in the half-cell test that the material not only has high mass specific capacity and specific energy, but the specific capacity is ordinary It is 1.5 to 2 times that of the cathode material of sodium ion batteries, and has a good cycle life. It has great practical value and can be used for large-scale energy storage in solar power generation, wind power generation, smart grid peak regulation, distributed power stations, b...

Embodiment 2

[0076] This embodiment provides a preparation method of a sodium-lithium-iron-manganese-based layered oxide material, specifically a solid-phase method, such as Figure 4 shown, including:

[0077] Step 201, the stoichiometric 100wt%~108wt% sodium carbonate of the required sodium and the required stoichiometric lithium hydroxide and / or lithium carbonate, iron oxide and / or ferric oxide and manganese dioxide are mixed in proportion to form Precursor;

[0078] Step 202, using a ball milling method to uniformly mix the precursor to obtain a precursor powder;

[0079] Step 203, placing the precursor powder in a muffle furnace, and heat-treating it in an air atmosphere at 600° C. to 1000° C. for 2 to 24 hours;

[0080] Step 204, grinding the heat-treated precursor powder to obtain a sodium-lithium-iron-manganese-based layered oxide material.

[0081] The preparation method of the sodium-lithium-iron-manganese-based layered oxide material provided in this embodiment can be used to...

Embodiment 3

[0083] This embodiment provides a preparation method of a sodium-lithium-iron-manganese-based layered oxide material, specifically a spray drying method, such as Figure 5 shown, including:

[0084] Step 301, the stoichiometric 100wt%~108wt% sodium carbonate of the required sodium and the required stoichiometric lithium hydroxide and / or lithium carbonate, iron oxide and / or ferric oxide and manganese dioxide are mixed in proportion to form Precursor;

[0085] Step 302, adding ethanol or water to the precursor and stirring evenly to form a slurry;

[0086] Step 303, spray-drying the slurry to obtain a precursor powder;

[0087] Step 304, placing the precursor powder in a muffle furnace, and heat-treating in an air atmosphere at 600° C. to 1000° C. for 2 to 24 hours;

[0088] Step 305, grinding the heat-treated precursor powder to obtain a sodium-lithium-iron-manganese-based layered oxide material.

[0089] The preparation method of the sodium-lithium-iron-manganese-based lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com