Absorbable expansion type nano short fiber powdery material as well as preparation method and application thereof

A technology for absorbing swelling and powdery materials, applied in applications, pharmaceutical formulations, medical science, etc., can solve the problems of high tap density hemostatic powder, fracture, etc., and achieve excellent flow properties, ultra-high tap density, and good water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

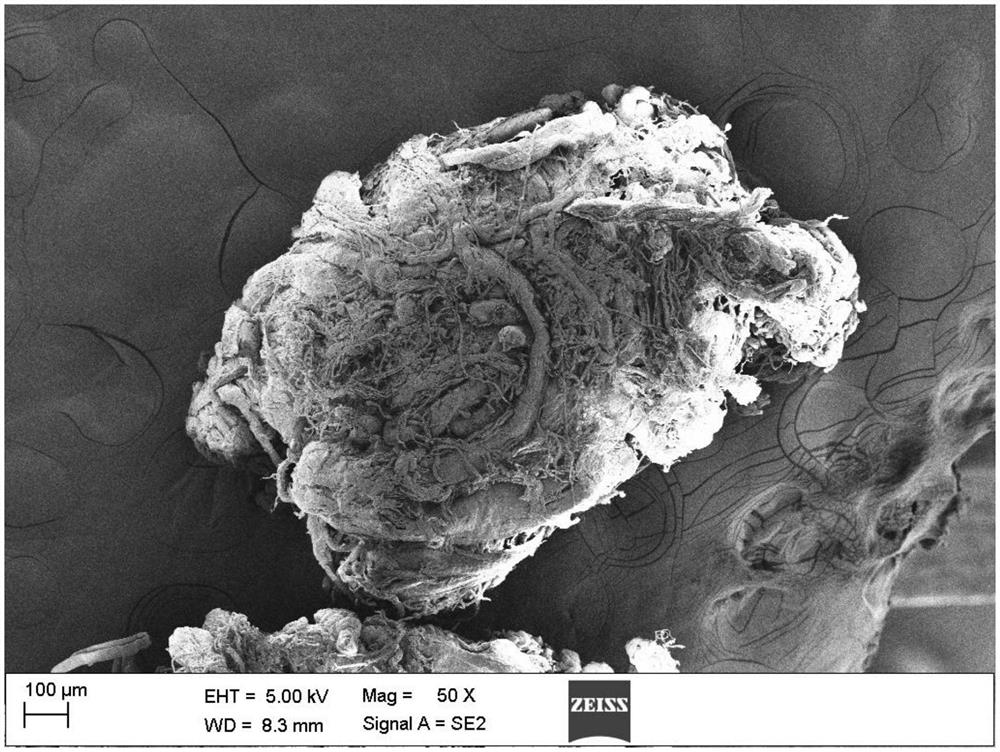

Image

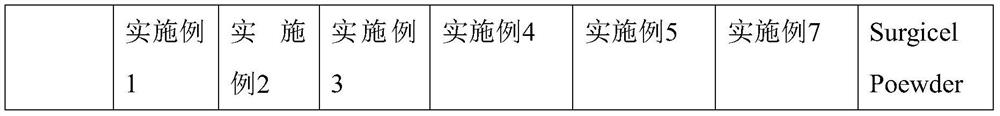

Examples

preparation example Construction

[0034] In a second aspect, the present invention provides a preparation method according to the first aspect of the present invention, the method comprising the following steps:

[0035] (1) Electrospinning step: preparing the nanofiber material from the fiber material by electrospinning;

[0036] (2) Crosslinking treatment step: the nanofiber material is modified and crosslinked to obtain a modified nanofiber material; preferably, the chemical crosslinking agent selected for the modified crosslinking treatment is selected from carbodiimide, One or more of the group consisting of carbodiimide / N-hydroxysuccinimide, genipin and aldehydes;

[0037](3) shearing treatment step: performing shearing treatment on the modified nanofiber material to obtain fluffy nano short fiber clusters;

[0038] (4) Preforming treatment: the fluffy nano-short fiber clusters are crystallized by liquid nitrogen low-temperature forming treatment so as to maintain a three-dimensional space network struc...

Embodiment 1

[0082] (1) Dissolving gelatin (Gelatin) in trifluoroethanol, wherein the mass concentration of gelatin is 6% (g / mL), stirring and dissolving to obtain a uniform polymer solution, which is the spinning stock solution. The polymer solution is placed in the electrospinning syringe, the speed of the micro-injection pump is adjusted to 5mL / h, the voltage of the high voltage generator is adjusted to 25kV, the receiving distance of the receiving device is adjusted to 12cm, and the relative humidity of the spinning environment is set to 40%, the ambient temperature is 30°C, and the electrospinning is carried out. Through the high-voltage electrospinning technology, the nanofiber material which is interwoven by fiber filaments and has a porous structure is prepared.

[0083] (2) In a 500mL beaker, add 225mL of absolute ethanol solution, then add 25mL of aqueous solution, stir and mix well, then weigh 3.57g of carbodiimide and 1.43g of N-hydroxysuccinimide and dissolve them in the above...

Embodiment 2

[0088] (1) Dissolve the hydroxypropylmethylcellulose (HPMC) material in a mixed solution of hexafluoroisopropanol and water, wherein the concentration of hydroxypropylmethylcellulose is 10% (g / mL), stir and dissolve A homogeneous polymer solution was obtained. At the same time, a certain mass of fibrinogen (coagulation factor) was weighed and dissolved in the above polymer solution. The polymer solution is placed in the electrospinning syringe, the speed of the micro-injection pump is adjusted to 5mL / h, the voltage of the high voltage generator is adjusted to 38kV, the receiving distance of the receiving device is adjusted to 10cm, and the relative humidity of the spinning environment is set to 30%, the ambient temperature is 40°C, electrospinning is carried out, and the porous nanofiber material composited with coagulation factors is prepared through high-voltage electrospinning technology.

[0089] (2) In a 500mL beaker, add 150mL of anhydrous isopropanol solution, then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com