Preparation method of two-dimensional anion exchange polymer, prepared polymer and application thereof

An anion and polymer technology, which is applied in the field of preparation of two-dimensional anion exchange polymers, can solve the problems of lack of synthesis methods and inappropriate preparation of two-dimensional polymers, and achieve the effect of facilitating efficient conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

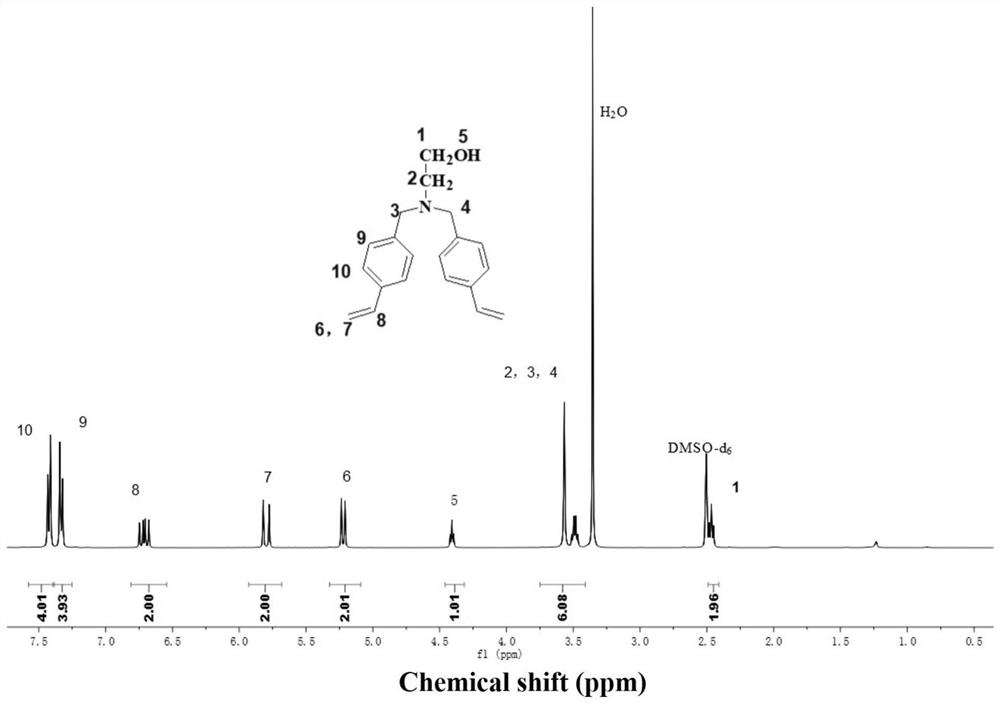

[0066] The preparation method of monomer A1 specifically comprises the following steps:

[0067] Synthesis of Intermediate I: In a 100mL single-necked flask, first ethanolamine (1.02g, 0.0167mol), triethylamine (Et 3 N, 3.38g, 0.0334mol) and acetonitrile (20mL) were stirred and miscible, and then 4-chloromethylstyrene solution was added dropwise, and the reaction was stirred at room temperature for 24 hours. After removing the white solid by filtration, the solution was extracted with ethyl acetate. The extract was dried with anhydrous sodium sulfate, and the solvent was removed by rotary evaporation to obtain a crude product. The crude product was recrystallized in a mixed solvent of petroleum ether and ethyl acetate (40:1) to obtain intermediate I, namely N,N-bis(4-vinyl-benzyl)-2-hydroxyethylamine, the yield 90%.

[0068] Synthesis of monomer A1: In a 50mL reaction flask, add intermediate I (1.1971g, 4.08mmol) and acetonitrile (20mL), heat up to 40°C and stir to dissolve...

Embodiment 2

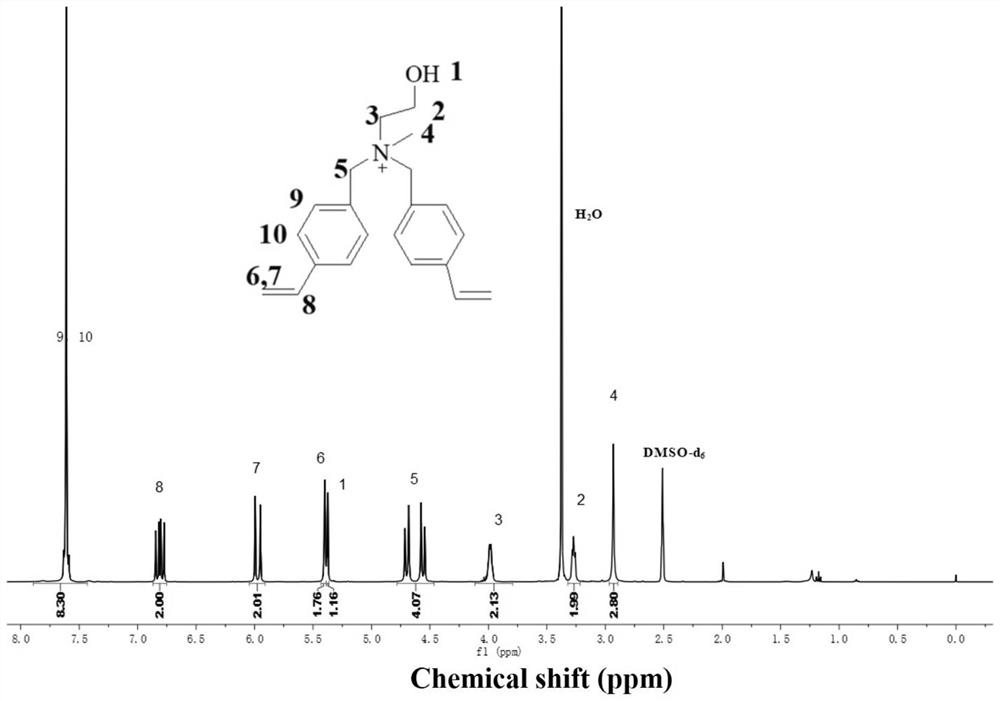

[0072] The preparation method of monomer B1 specifically comprises the following steps:

[0073] Intermediate II synthesis: in 100mL single-necked flask, add diethanolamine (2.19g, 20.87mmol), potassium carbonate (2.88g, 20.87mmol) and acetonitrile (30mL), add dropwise 4-chloromethylstyrene ( 3.50 g, 22.95 mmol) solution, stirred and reacted at room temperature for 24 hours. After filtering off the white solid, the filtrate was extracted with ethyl acetate. The extract was dried over anhydrous sodium sulfate and rotary evaporated to obtain a light yellow liquid as the crude product. The crude product was purified by silica gel chromatography (petroleum ether:ethyl acetate=20:1) to obtain intermediate II with a yield of 85%.

[0074] Synthesis of monomer B1: Add intermediate II (7g, 31.63mmol) and acetonitrile (20mL) into a three-necked flask, heat up to 40°C under stirring, then add methyl iodide (44.89g, 316.3mmol), and keep stirring at 40°C for 24 Hour. After the reactio...

Embodiment 3

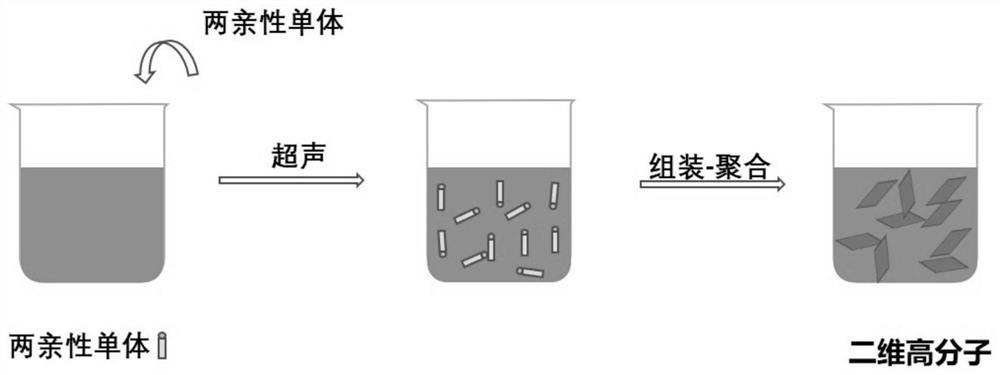

[0078] Monomer self-assembly, such as figure 1 As shown, it specifically includes the following steps:

[0079] In a 25mL reaction bottle, first add monomer A1 (100mg, 229.7μmol) and monomer B1 (1.67g, 4.594mmol), then add N,N dimethylformamide (10mL), and dissolve the monomer by ultrasonic to form solution, add an appropriate amount of water, and then stand at room temperature for 24 hours to self-assemble and obtain two-dimensional supramolecular aggregates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com