Preparation method and application of high-strength solid-state composite electrolyte film

A composite electrolyte and solid electrolyte technology, applied in the field of lithium secondary battery electrolyte, can solve the problems of low ionic conductivity, poor ionic conductivity, restricting the development and application of composite solid electrolyte system, achieve high ionic conductivity, ease interface The effect of resistance, excellent non-flammable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

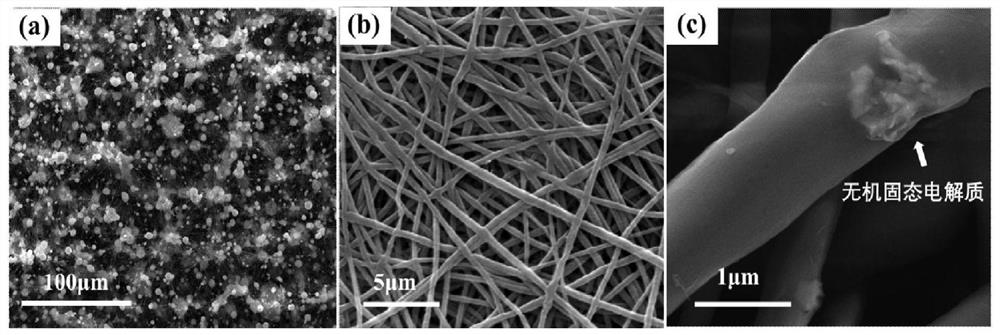

[0044] A polyacrylonitrile-coated Li 7 La 3 Zr 2 o 12 The preparation method of the fibrous membrane support material of nano particle, lithium salt, comprises the following steps:

[0045] 1) Prepare the spinning solution, weigh about 0.1gLi with an electronic analytical balance 7 La 3 Zr 2 o 12 Nanoparticles, dissolved in 8.8g of dimethylformamide, magnetically stirred for 2h, ultrasonically dispersed for 1h, then weighed 0.5g of lithium bistrifluoromethanesulfonimide and 1.2g of polyacrylonitrile, dissolved in it, magnetically stirred for 12h to Dissolve completely, let it stand for defoaming, and obtain a polyacrylonitrile solution with a concentration of about 11%, and the whole process is carried out in a glove box;

[0046] 2) Use an electrospinning device for spinning, transfer the spinning solution to the spinneret through an automatic injection device, connect the spinneret and the receiving device to the positive and negative electrodes of the high-voltage el...

Embodiment 2

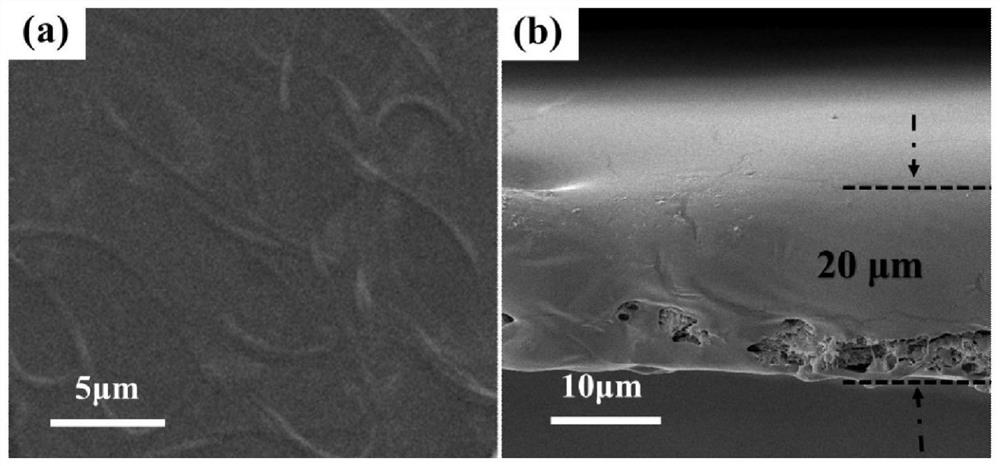

[0051] A method for preparing a wettable solid composite electrolyte material, comprising the following steps:

[0052] 1) Under the protection of argon gas with a purity of ≥99%, weigh 0.5 g of lithium bistrifluoromethanesulfonimide with an electronic analytical balance and dissolve it in 1 g of acetonitrile solution, stir magnetically for 0.5 h, and then weigh 0.46 g of polyoxygen After ethylene was mixed, it was stirred for 2h to obtain a transparent mixed solution.

[0053] 2) The mixed solution obtained in step (1) is drop-coated on the polyacrylonitrile-coated Li prepared in Example 1. 7 La 3 Zr 2 o 12 In the high-strength fiber porous membrane of nanoparticles and lithium salt, the mixed solution penetrates evenly to both sides of the fiber membrane to form a thin liquid film;

[0054] 3) In a vacuum oven, dry the composite at 60° C. for 24 hours to remove the organic solvent, and obtain a solid composite electrolyte material with a wettable electrolyte film.

[00...

Embodiment 3

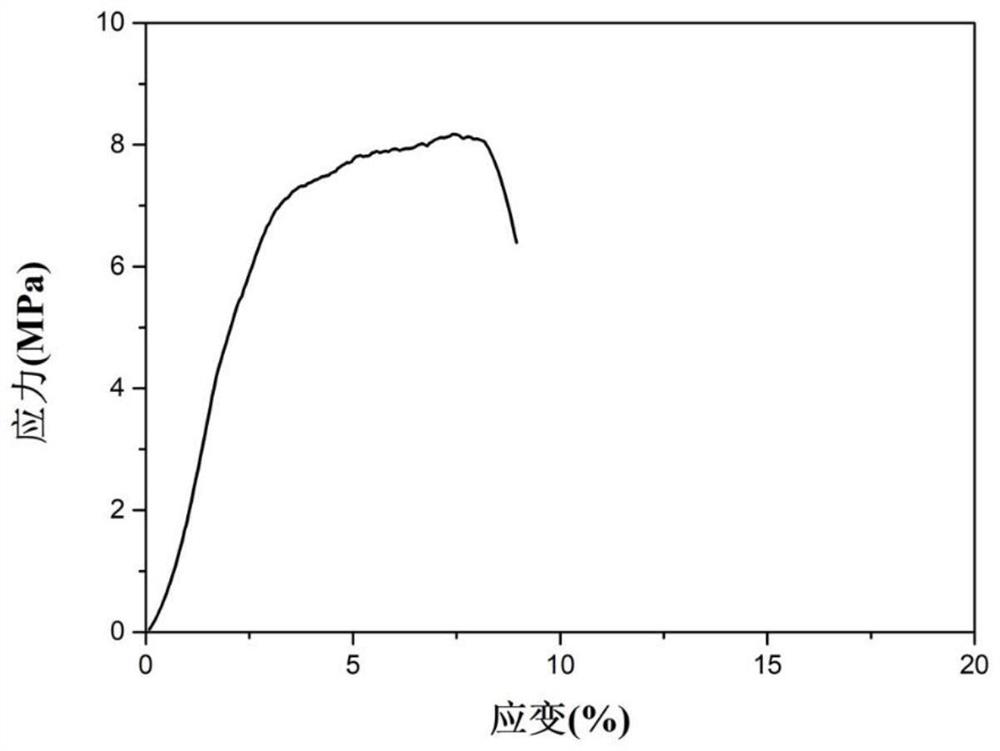

[0061] LiFePO prepared with solid composite electrolyte 4 / / The preparation and testing method of Li solid-state lithium battery, comprises the following steps:

[0062] 1) LiFePO 4 :Acetylene black:PVDF=80:10:10 ratio evenly coated on the aluminum foil, and dried in a constant temperature drying oven at 80°C for 8 hours, then cut the dried electrode sheet into Wafer;

[0063] 2) Cut the prepared solid composite electrolyte into Discs were placed in a glove box in an Ar atmosphere for use;

[0064] 3) The prepared LiFePO 4 Positive electrode materials, solid composite electrolyte film materials according to positive electrode shell, LiFePO 4The positive electrode material, solid composite electrolyte film, metal lithium sheet, gasket, shrapnel, and negative electrode case are assembled into a battery in sequence. The battery model is button battery 2032, and the whole process is carried out in a glove box;

[0065] 4) Electrochemical performance test of all-solid-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com