A kind of thermal protective coating for marine environment and preparation method thereof

A technology for marine environment and heat protection, applied in the field of coatings, can solve the problems that thermal protection coatings cannot be used for a long time, and achieve excellent marine environment resistance, high elasticity, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

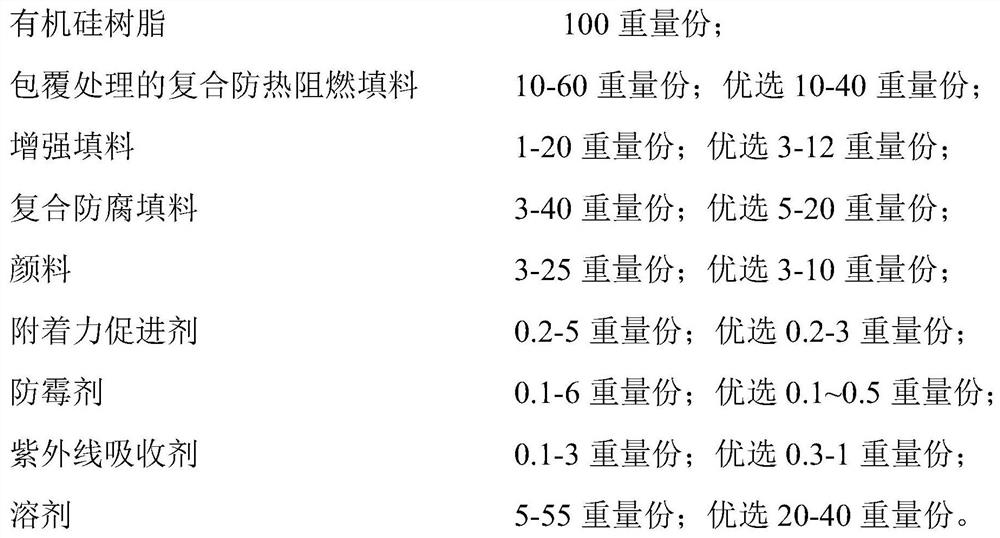

Method used

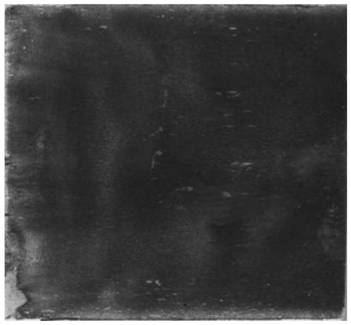

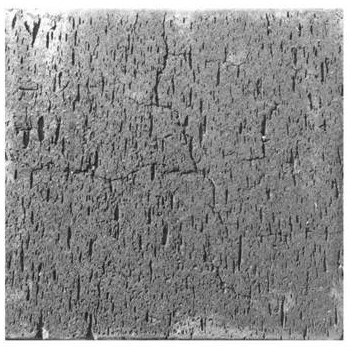

Image

Examples

Embodiment 1

[0098] Preparation of component A: Weigh 100 parts of epoxy-modified silicone resin, 18 parts of styrene-coated composite heat-resistant and flame-retardant fillers (composite heat-resistant fillers include: 6 parts of aluminum hydroxide, 2 parts of magnesium hydroxide , 5 parts of polyphosphate amine, 5 parts of pentaerythritol), 10 parts of nano calcium carbonate, 8 parts of aluminum tripolyphosphate, 0.3 parts of graphene, 7 parts of titanium dioxide, 0.6 parts of γ-methacryloxypropyl trimethoxysilane , 0.2 parts of Fusheng 3306 leveling agent, 0.8 parts of Ona F400 wetting and dispersing agent, 0.4 parts of Tianshi Landun LD06 antifungal agent, 0.5 parts of 2-hydroxy-4-n-octyloxybenzophenone, ethyl acetate 25 parts, use a high-speed mixer to disperse for 22 minutes, control the speed at 2400r / min, then transfer the coating to a three-roller machine, grind to a fineness of <100μm, use a 30-100 mesh copper mesh to filter, and pack to obtain A component.

[0099] Preparation ...

Embodiment 2

[0105] Preparation of component A: Weigh 100 parts of polyurethane modified silicone resin, 35 parts of composite heat-resistant and flame-retardant filler coated with melamine resin (composite heat-resistant filler includes: 14 parts of aluminum hydroxide, 4 parts of magnesium hydroxide, 10 parts of amine polyphosphate, 7 parts of pentaerythritol), 4 parts of barium sulfate, 13 parts of modified aluminum molybdenum polyphosphate, 5 parts of zinc oxide, 0.5 parts of carbon black, 0.4 parts of γ-glycidyl etheroxypropyl trimethoxysilane, Fenghong FHT-F3010 leveling agent 0.5 parts, Fenghong FHT-F4010 wetting and dispersing agent 1.2 parts, Lanfeng OIT antifungal agent 0.2 parts, 2-(2'-hydroxy-5'-tert-octylphenyl)benzene 0.6 parts of triazole and 30 parts of butyl acetate were dispersed with a high-speed mixer for 40 minutes, and the speed was controlled at 850 r / min. Then, the paint was transferred to a three-roll machine, ground to a fineness of <100 μm, and filtered with a 30-1...

Embodiment 3

[0112] Weigh 100 parts of polyester modified silicone resin, 33 parts of epoxy resin-coated composite heat-proof filler (composite heat-proof filler includes: 7 parts of aluminum hydroxide, 7 parts of magnesium hydroxide, and 12 parts of polyphosphate amine) , 7 parts of pentaerythritol), 5 parts of white carbon black, 3 parts of mica powder, 3 parts of calcium polyphosphate, 12 parts of zinc phosphate, 4 parts of iron red, 1.2 parts of γ-aminopropyl triethoxysilane, Fenghong FHT -0.5 parts of F3077 leveling agent, 2.8 parts of Fenghong FHT-F4035 wetting and dispersing agent, 0.4 parts of praise AM5700-C antifungal agent, 0.9 parts of 2-hydroxy-4-methoxybenzophenone, 22 parts of cyclohexanone Use a high-speed mixer to disperse for 30 minutes, control the speed at 1500r / min, then transfer the paint to a three-roll machine, grind it to a fineness of <100 μm, filter it with a 30-100-mesh copper mesh, and pack it to obtain Component A.

[0113] Preparation of component B: Weigh 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com