Heat-resistant low-temperature-curing epoxy glue

A technology of epoxy adhesive and heat resistance, applied in the field of epoxy adhesive, can solve the problem of not being able to meet the requirements of good low-temperature curing, heat resistance of adhesion, and resistance to moisture and heat aging at the same time, so as to ensure storage stability and strong adhesion. Relay, high flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

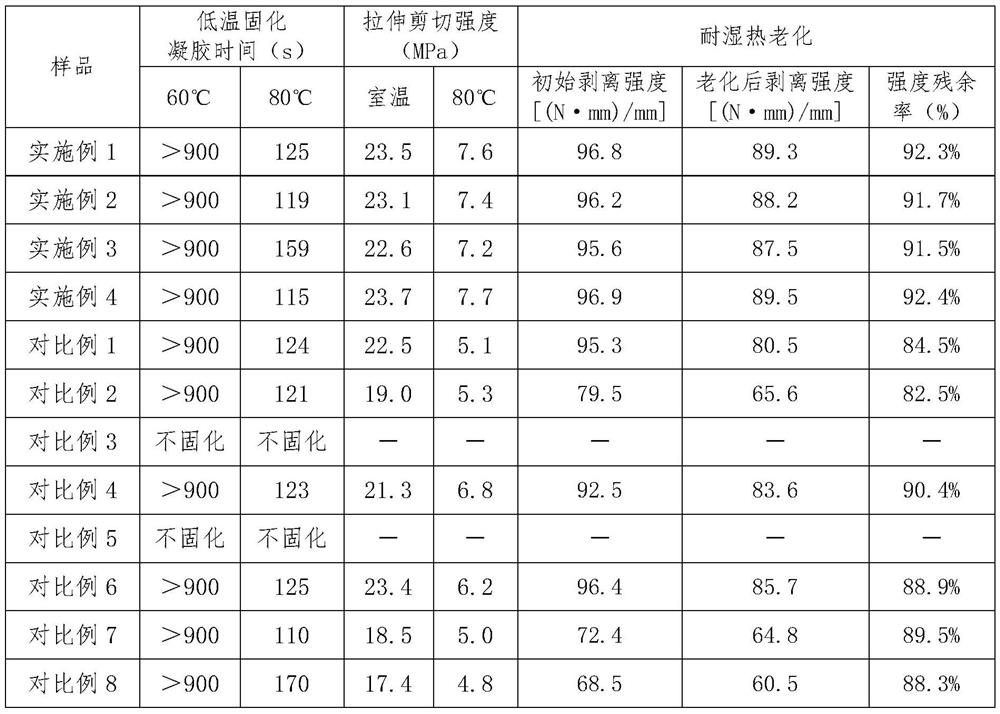

Examples

preparation example Construction

[0035] Curing agent is an indispensable raw material for the preparation of epoxy adhesives. Generally speaking, curing agents include aliphatic amine curing agents, aromatic amine curing agents, imidazole curing agents, acid anhydride curing agents and polythiol curing agents. agent etc. Based on the consideration of the low-temperature curing performance of the obtained epoxy glue, in a preferred embodiment, the curing agent of the present invention selects a combination of polyfunctional thiol and difunctional thiol, that is, the system of the present invention contains polyfunctional thiol, bifunctional Two types of curing agent materials of functional thiol. Among them, polyfunctional thiol is mainly used for cross-linking curing reaction, and difunctional thiol can realize the function of chain extension. The reasonable combination of two polythiol curing agents can ensure that the epoxy adhesive has more suitable cross-linking density and flexibility. sexual balance. ...

Embodiment 1

[0047] Embodiment 1 of the present invention provides a heat-resistant low-temperature curing epoxy adhesive, including the following components in parts by mass: 50 parts of bisphenol A epoxy resin, 45 parts of hydrogenated bisphenol A epoxy resin, hydroxyl-terminated poly 5 parts of ether ether ketone, 70 parts of curing agent 1,3,4,6-tetramercaptopropyl imidazo[4,5-D]imidazole-2,5[1H,2H]-dione, 1,3 parts of curing agent -20 parts of bis(3-mercaptopropyl)benzimidazol-2-one, 2 parts of solid dispersion latent curing agent, 0.4 part of stabilizer triisopropyl borate, antioxidant tetrakis[β-(3,5- 0.3 parts of di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 2 parts of silane coupling agent γ-glycidyl etheroxypropyl trimethoxysilane, 20 parts of nano silicon dioxide, 5 parts of nano calcium carbonate .

[0048] After measuring the above-mentioned quantitative materials in the container, use dispersing equipment, mix well at room temperature or low temperature, ...

Embodiment 2

[0050] Embodiment 2 of the present invention provides a heat-resistant low-temperature curing epoxy adhesive, including the following components in parts by mass: 60 parts of bisphenol A epoxy resin, 35 parts of hydrogenated bisphenol A epoxy resin, hydroxyl-terminated poly Ether ether ketone 5 parts, curing agent 1,3,4,6-tetramercaptoethylimidazo[4,5-D]imidazole-2,5[1H,2H]-dione 80 parts, curing agent butanediol 20 parts of bis(3-mercaptobutyrate) ester, 2 parts of solid dispersion latent curing agent, 0.4 part of triethyl borate as stabilizer, antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl ) 0.3 parts of octadecyl propionate, 2 parts of silane coupling agent γ-glycidyl etheroxypropyl trimethoxysilane, and 25 parts of nano silicon dioxide.

[0051] After measuring the above-mentioned quantitative materials in the container, use dispersing equipment, mix well at room temperature or low temperature, and perform defoaming treatment, and the target product epoxy glue is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com