Composite diaphragm as well as preparation method and application thereof

A composite diaphragm and composite coating technology, applied in the field of lithium ion batteries, can solve the problems of increased air permeability of composite diaphragms, increased internal resistance of lithium ion batteries, low product production efficiency, etc., and achieves good electrolyte wettability. , The effect of improving thermal stability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] This embodiment provides a method of preparing a composite diaphragm, the method comprising the steps of:

[0087] (1) Aluminum oxide, polystyrene acrylate, and the specific surface area of the alumina is 6m. 2 / g, the particle diameter is 1.5 μm, the polystyrene acrylate has a molecular weight of 150W, a glass transition temperature of 5 ° C, stirred to dissolve, a mixed slurry having a viscosity of 55 cp, a solid content of 45%;

[0088] With the total mass of aluminum oxide and polystyrene acrylate, the total mass percentage of the alumina was 93%, and the mass content of the polystyrene acrylate was 7%;

[0089] (2) The mixed slurry obtained by step (1) is applied to one side of the polyvinyl group, the polyvinyl group having a thickness of 9 μm, a porosity of 40%, dried to obtain the composite diaphragm .

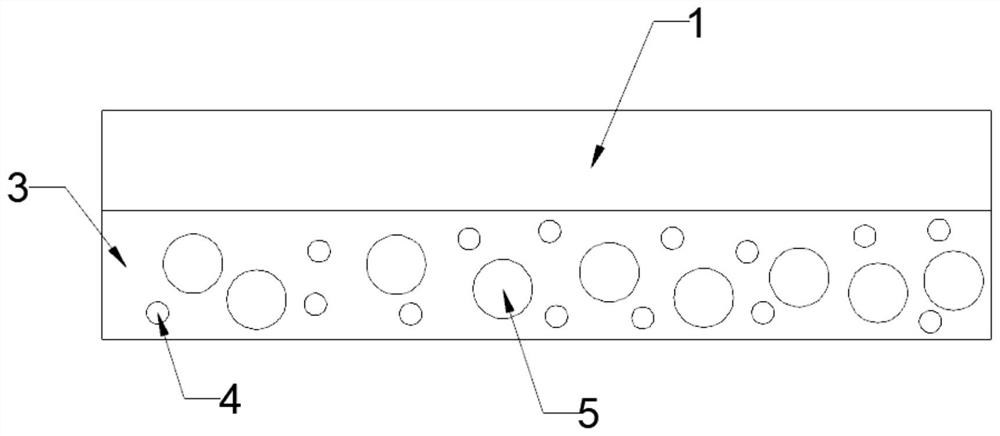

[0090] The composite diaphragm obtained in this example, such as figure 1 As shown, the composite coating has a thickness of 3 μm, and a composite coating SEM el...

Embodiment 2

[0092] This embodiment provides a method of preparing a composite diaphragm, the method comprising the steps of:

[0093] (1) Aluminum oxide, polystyrene acrylate, and the specific surface area of the alumina is 8m. 2 / g, the particle diameter is 0.2 μm, the polystyrene acrylate is 100 W, the glass transition temperature is 10 ° C, stirred to dissolve, the viscosity is 50 cp, the solid content of 30% is a mixed slurry;

[0094] With the total mass of the alumina and the polystyrene acrylate, the total mass content of the alumina is 95%, and the mass content of the polystyrene acrylate is 5%;

[0095] (2) The mixed slurry obtained by step (1) is applied to both sides of the polyvinyl group, the polyvinyl group having a thickness of 9 μm, a porosity of 45%, dried to obtain the composite diaphragm .

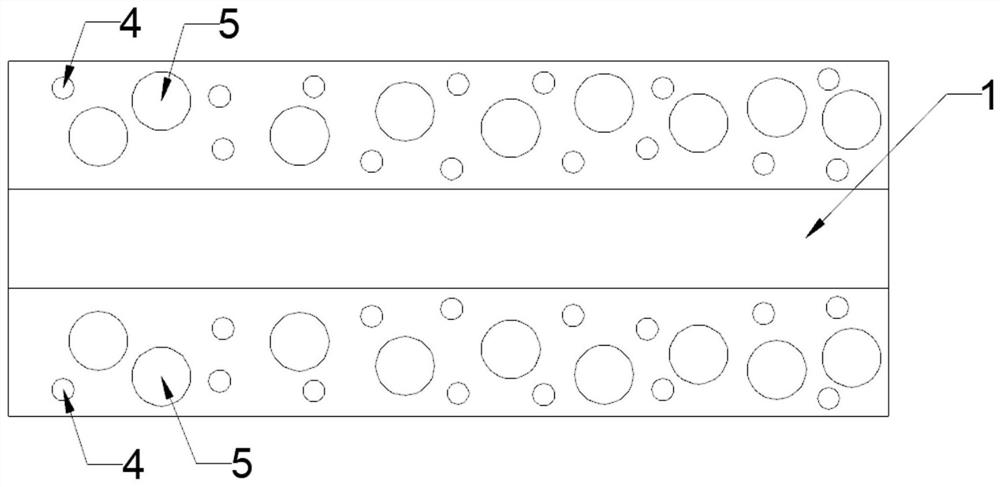

[0096] The composite diaphragm obtained in this example, such as figure 2 As shown, the composite coating has a thickness of 2 μm.

Embodiment 3

[0098] This embodiment provides a method of preparing a composite diaphragm, the method comprising the steps of:

[0099] (1) In the addition of polystyrene acrylate, the polystyrene acrylate has a molecular weight of 200W, a glass transition temperature of -10 ° C, stirred to dissolve, and boehmite, the specific surface area of the boehmite is 9M 2 / g, the particle size is 1 μm, stirred and mixed, and the viscosity is 60 cp, the solid content of 50% is mixed;

[0100] With the total mass of the boehmite and the polystyrene acrylate, the total mass content of the boehmite is 97%, and the mass content of the polystyrene acrylate is 3%. ;

[0101] (2) Getting polyfial fluoride to stir in water to dissolve, add boehmite, and the specific surface area of the boeh is 6m. 2 / g, the particle diameter is 2 μm, stirred well, resulting in a ceramic slurry having a viscosity of 65 cp, a solid content of 50%;

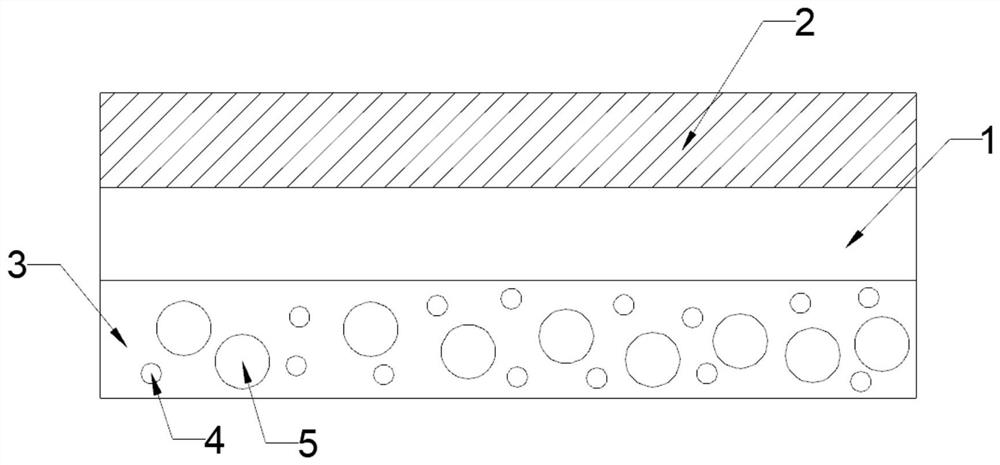

[0102] With the total mass of the boehmite and polyvinylidene fluoride, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com