Photothermal conversion material and application thereof in seawater desalination and salt recovery

A light-to-heat conversion material and heat insulation layer technology, applied in the fields of material chemistry and solar energy conversion, can solve the problems of low mechanical strength and high cost of materials, achieve high chemical and structural stability, low preparation cost, and high solar energy conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

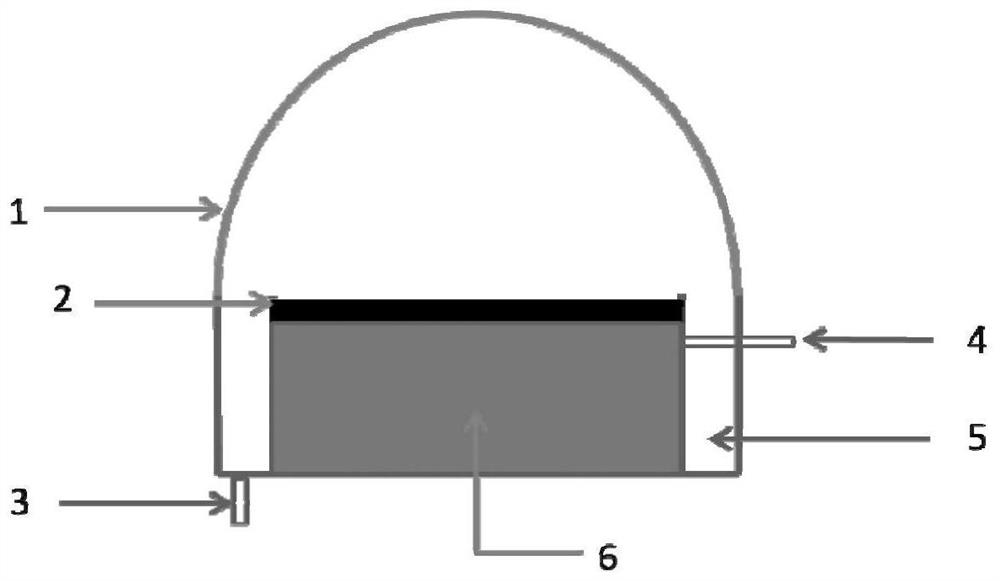

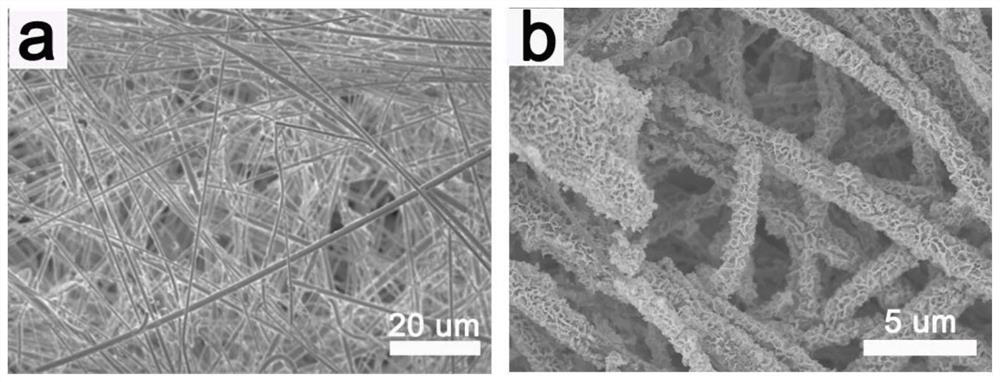

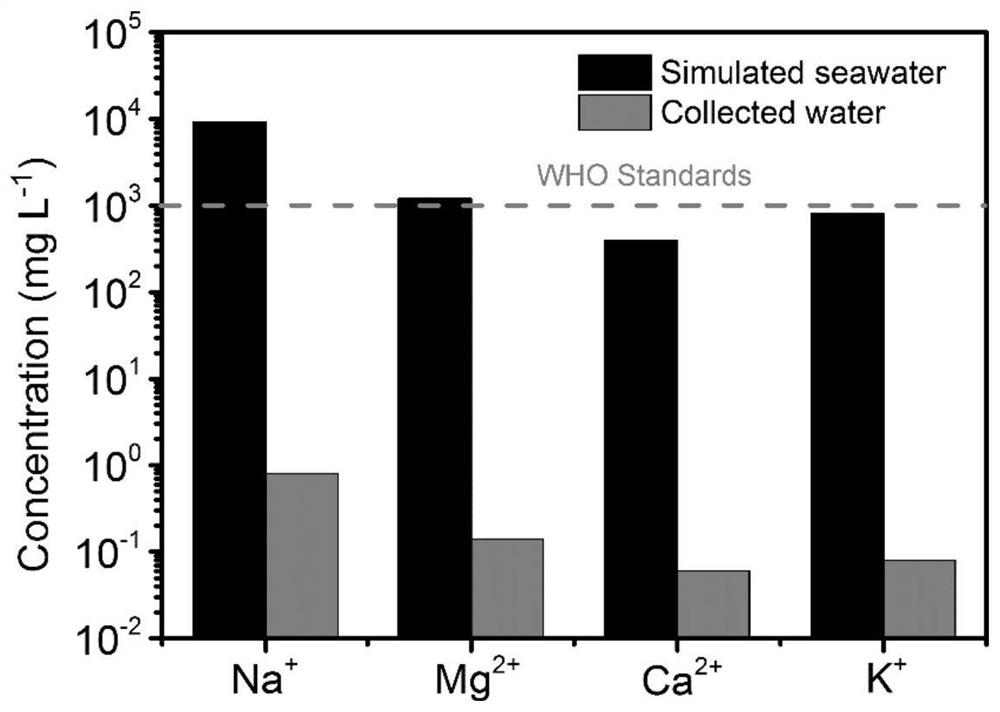

[0057] A method for preparing a photothermal conversion material, comprising the following steps: substrate cleaning, growth reaction, vulcanization reaction, and drying. Soak the commercial glass fiber membrane in 1M hydrochloric acid solution containing 0.4wt% aniline monomer, add 20mL of 2wt% ammonium persulfate aqueous solution dropwise to the solution, and react at 0°C for 3h to obtain a glass fiber membrane with a polyaniline layer . After washing and drying the glass fiber membrane, put it into an ethanol solution containing cobalt chloride (0.27wt%), nickel chloride (0.2wt%) and urea (0.11wt%) for hydrothermal reaction, and the reaction temperature is 130°C. The time is 6h, so that the continuous sheet-like cobalt-nickel precursor is generated in situ on the surface of the glass fiber. Finally, wash and dry the prepared fiber membrane and vulcanize it in a tube furnace. The sulfur powder and the glass fiber membrane are placed side by side, the sulfur powder is locate...

Embodiment 2

[0060] Cut the industrial glass fiber cloth into a square of 3cm in length and width, wash and dry it, soak it in 1M hydrochloric acid solution containing 0.4wt% aniline monomer, add 20mL of 2wt% ammonium persulfate aqueous solution to the solution dropwise, and react at 0°C for 3h , to obtain a glass fiber cloth with a polyaniline layer grown on it. After the glass fiber cloth obtained after the reaction is washed and dried, put into the ethanol solution containing cobalt chloride (0.27wt%), nickel chloride (0.2wt%) and urea (0.11wt%) to carry out hydrothermal reaction, and the reaction temperature is 130 ℃, the reaction time is 6h, so that the continuous sheet-like cobalt-nickel precursor is generated in situ on the surface of the glass fiber. Finally, the prepared glass fiber cloth was washed and dried, and vulcanized in a tube furnace. The sulfur powder and glass fiber cloth were placed side by side, and the sulfur powder was located on the side near the air inlet. The rea...

Embodiment 3

[0063] Soak the glass fiber membrane in 40mL of 0.5M hydrochloric acid solution containing 1wt% aniline monomer, add 10mL of 2wt% ammonium persulfate aqueous solution dropwise to the solution, and react at 0°C for 6h to obtain a glass fiber membrane with a polyaniline layer . After the glass fiber membrane is washed and dried, it is put into an ethanol solution containing cobalt chloride (0.27wt%), nickel chloride (0.2wt%) and urea (0.11wt%) for hydrothermal reaction. The reaction temperature is 130 ° C, and the reaction time is 6h, so that the continuous sheet-like cobalt-nickel precursor is generated in situ on the surface of the glass fiber. Finally, the prepared fiber membrane was washed and dried, and vulcanized in a tube furnace. The sulfur powder and the glass fiber membrane were placed side by side, and the sulfur powder was located on the side near the air inlet. Fiber-film light-to-heat conversion materials.

[0064] The glass fiber film photothermal material has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com