Nano flower-shaped zinc cadmium sulfide solid solution photocatalyst and preparation method thereof

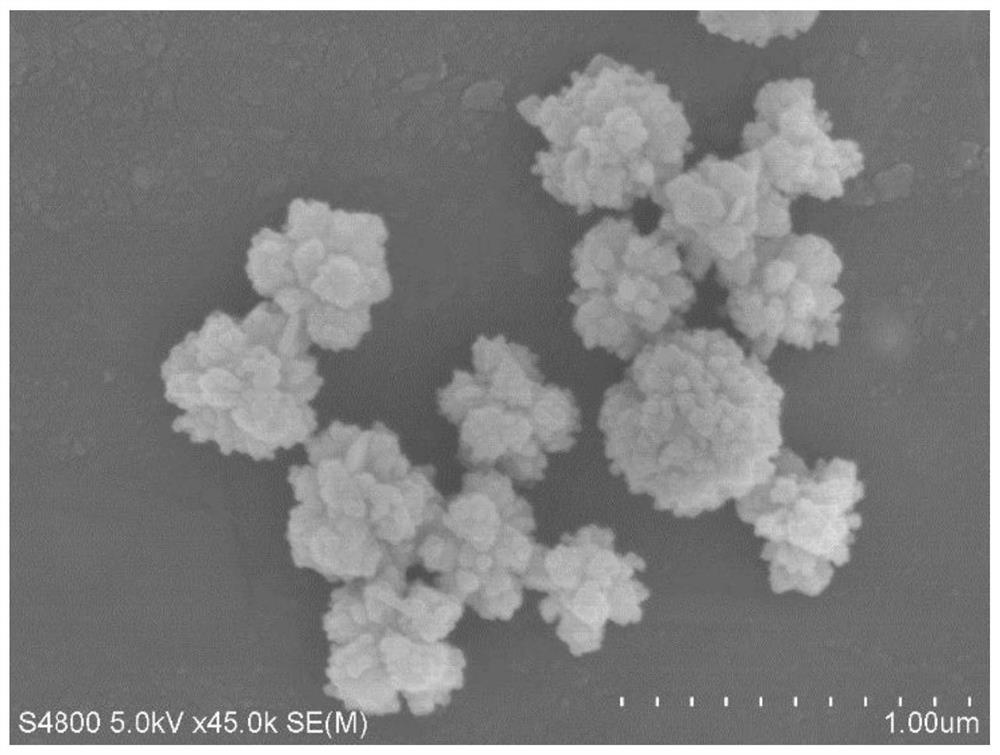

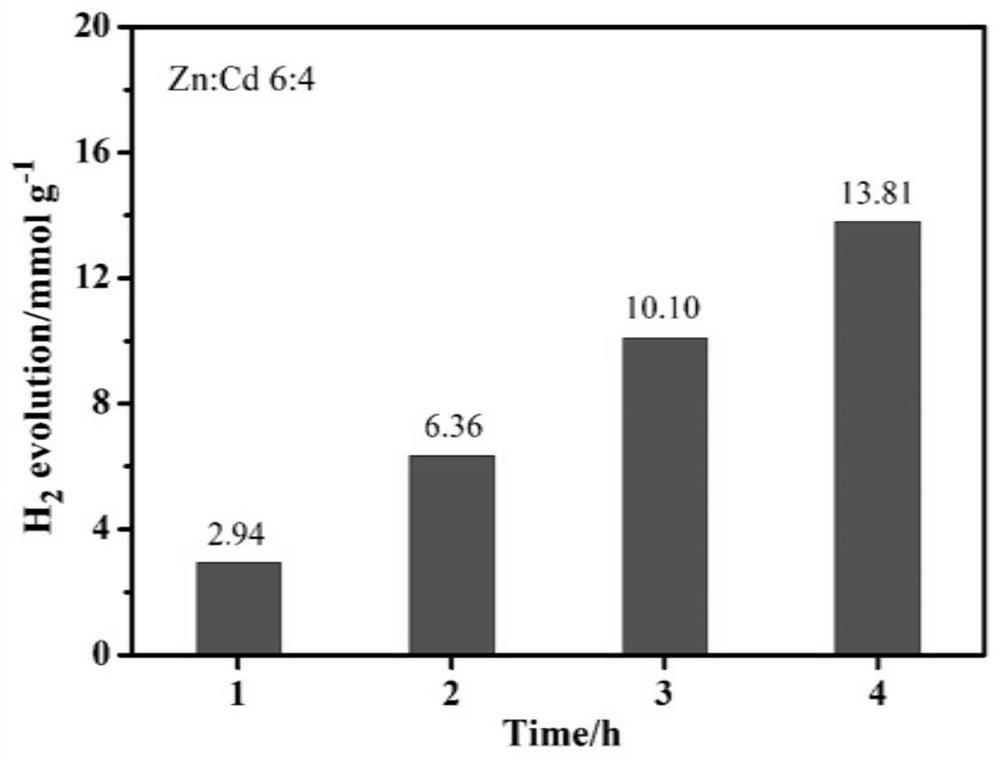

A zinc-cadmium sulfide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult control of reaction rate, easy sintering or melting of products, and large energy consumption. The effect of increasing reactive sites, improving photocatalytic performance, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

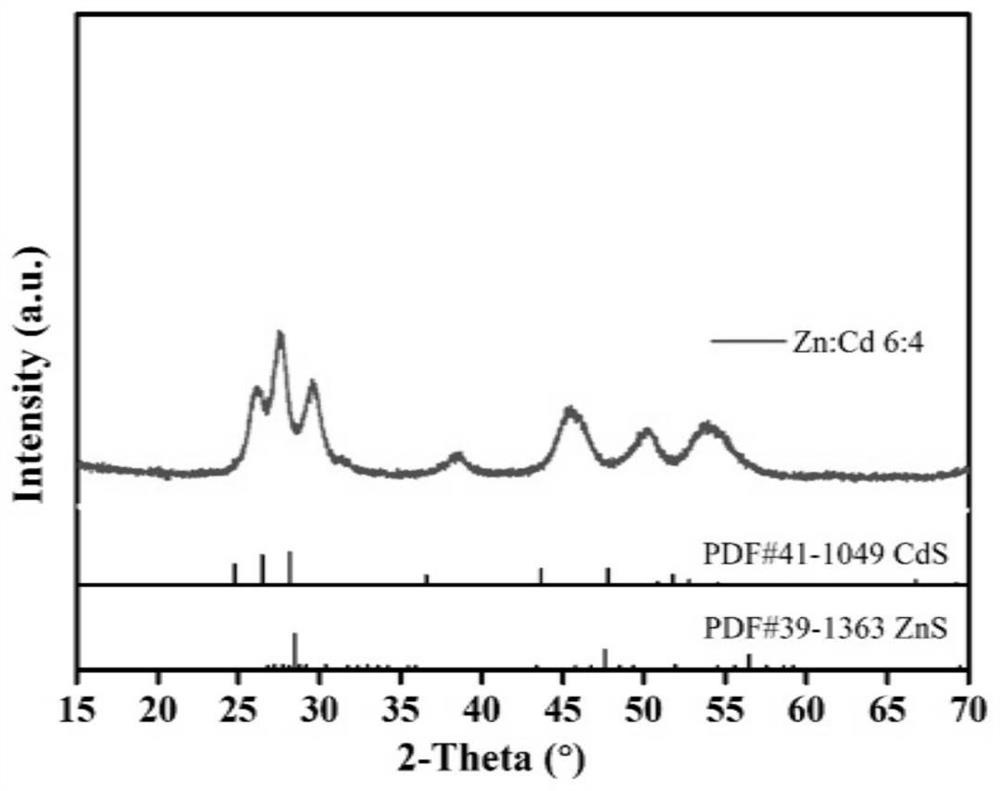

[0025] A kind of nano-flower-like Zn of multi-level structure of the present invention 0.6 Cd 0.4 The preparation method of S solid solution photocatalyst comprises the following steps:

[0026] Step 1: Take a certain amount of 1,2-diaminopropane and dissolve it in 2-6ml of deionized water to make a solution with a concentration of 0.4-1mmol / L. Stir with a magnetic stirrer at room temperature for 10-30min at a speed of 200 ~500r / min to obtain solution A;

[0027] Step 2: Using zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and cadmium acetate dihydrate (Cd(Ac) 2 2H 2 O) is raw material (n Zn :n Cd =6:4), and weigh 1 to 3 mmol of zinc acetate dihydrate, add it into solution A, and stir it magnetically for 20 to 40 minutes to form solution B.

[0028] Step 3: Use sodium hydrosulfide as the sulfur source, weigh 2-6 mmol, add it into solution B, and perform magnetic stirring for 20-40 minutes at a speed of 200-500 r / min to form solution C.

[0029] Step 4: Add solution C to the...

Embodiment 1

[0032] A kind of nano-flower-like Zn of multi-level structure of the present invention 0.6 Cd 0.4The preparation method of S solid solution photocatalyst comprises the following steps:

[0033] 1) Dissolve 2ml of 1,2-diaminopropane in 60ml of deionized water to make a solution with a concentration of 0.4mmol / mL. Stir with a magnetic stirrer at room temperature for 10min at a speed of 400r / min to obtain solution A.

[0034] 2) Using zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and cadmium acetate dihydrate (Cd(Ac) 2 2H 2 O) is raw material, weighs 1.2mmol and 0.8mmol respectively, adds in the mixed solution A, carries out magnetic stirring after 30min, forms the solution B.

[0035] 3) Sodium hydrosulfide was used as the sulfur source, 3 mmol was weighed, added to solution B, and magnetically stirred at 500 r / min for 25 minutes to form solution C.

[0036] 4) The solution C is added into the polytetrafluoroethylene lining, the filling ratio is controlled at 60%, the reaction ...

Embodiment 2

[0039] A kind of nano-flower-like Zn of multi-level structure of the present invention 0.6 Cd 0.4 The preparation method of S solid solution photocatalyst comprises the following steps:

[0040] 1) Dissolve 3.5ml of 1,2-diaminopropane in 50ml of deionized water to make a solution with a concentration of 0.8mmol / L. Stir with a magnetic stirrer at room temperature for 10min at a speed of 450r / min to obtain solution A.

[0041] 2) Using zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and cadmium acetate dihydrate (Cd(Ac) 2 2H 2 O) is raw material, weighs 1.8mmol and 1.2mmol respectively, adds in the mixing solution A, carries out magnetic stirring after 35min, forms the solution B.

[0042] 3) Using sodium hydrosulfide as the sulfur source, weigh 5 mmol, add it into solution B, and perform magnetic stirring at 500 r / min for 25 minutes to form solution C.

[0043] 4) The solution C is added to the polytetrafluoroethylene lining, the filling ratio is controlled at 50%, the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com