Organic fertilizer without livestock manure and production process thereof

A technology of organic fertilizer and manure, applied in the field of organic fertilizer without poultry and livestock manure and its production process, can solve the problems of lack of utilization of agricultural waste, easy breeding of harmful bacteria, high water content, etc., and improve resistance to adversity and disease Insect fungus ability, shorter fermentation cycle, strong moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

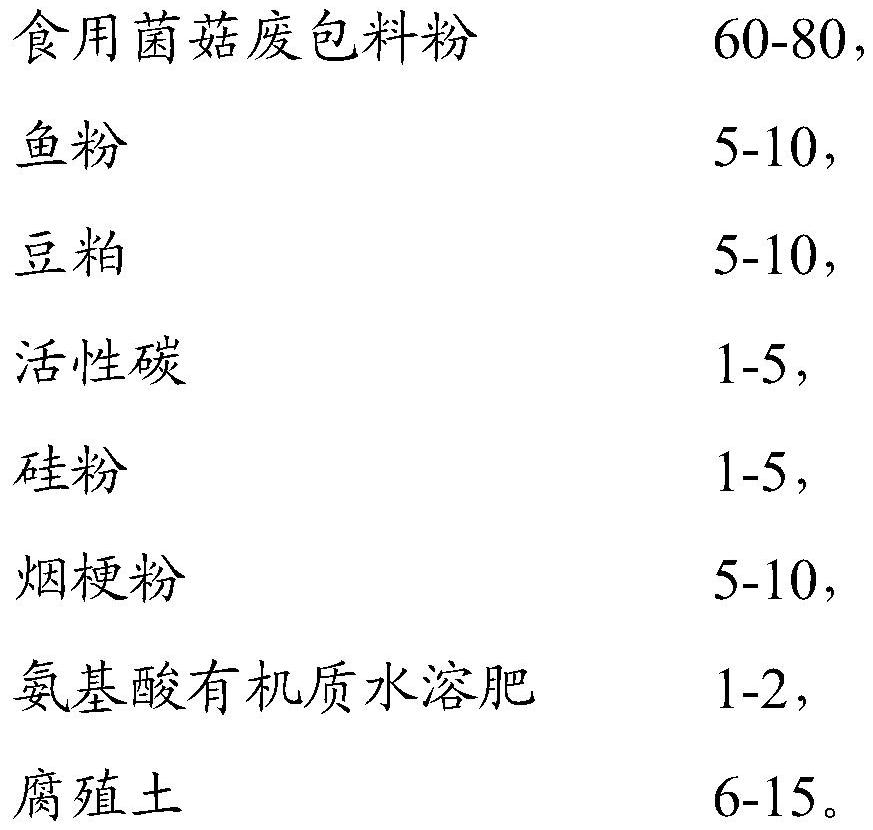

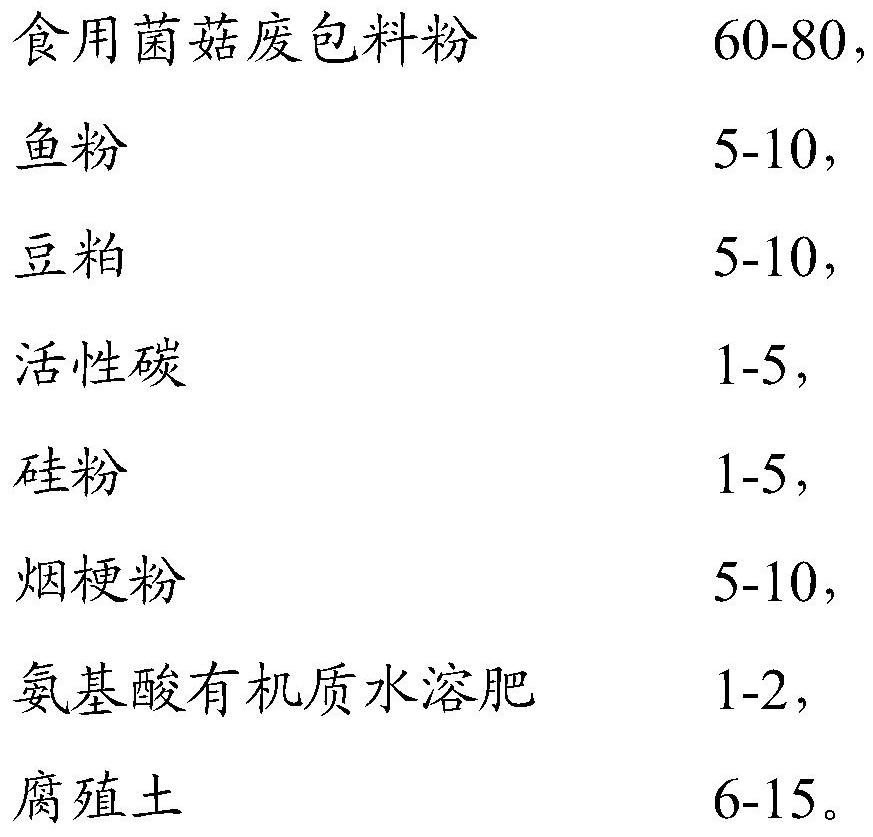

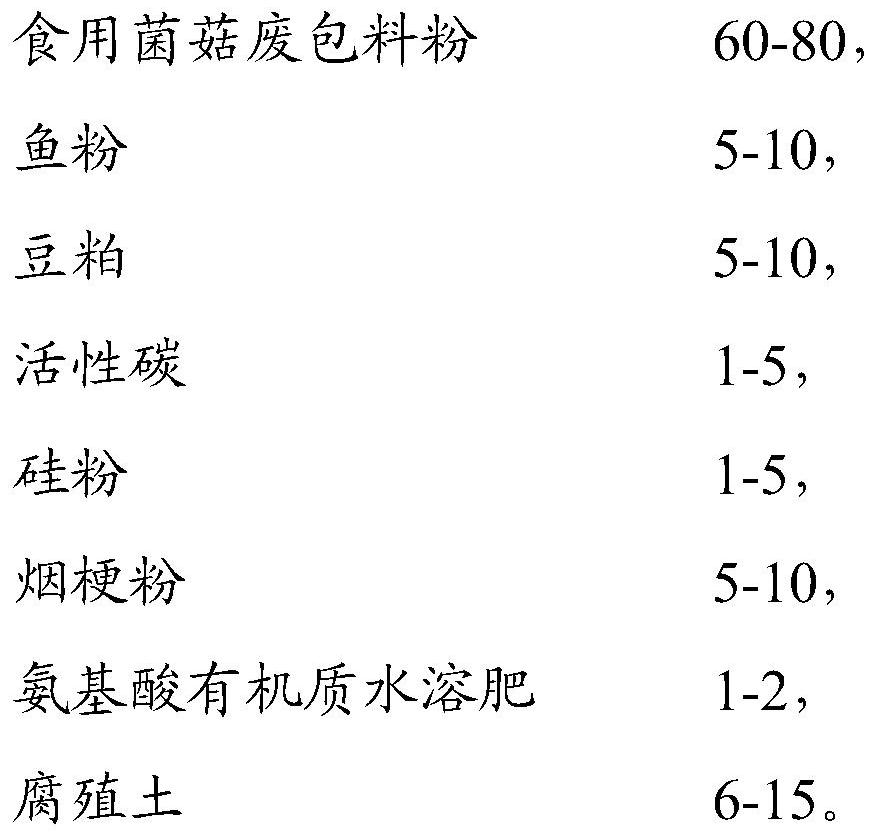

[0025] An organic fertilizer without poultry and livestock manure, comprising edible fungus and mushroom waste packaging powder, fish meal, soybean meal, activated carbon, silicon powder, tobacco stem powder, humus and amino acid organic matter water-soluble fertilizer, said poultry and livestock manure-free The parts by weight of each component in the organic fertilizer are as follows:

[0026]

[0027] In this embodiment, the particle size of the edible fungus mushroom waste packaging material powder is 50 mesh to 200 mesh, the optimal size is 80 mesh; the particle size of the activated carbon is 60 mesh to 100 mesh; the particle size of the silicon powder is 60 mesh. Mesh to 200 mesh, preferably 80 mesh; the particle size of the humus soil is 30 mesh to 200 mesh. Such setting makes the soil permeability after the application of the organic fertilizer of the technical scheme good, the moisture retention and fertilizer retention ability is strong, and it is convenient for ...

Embodiment 2

[0031] A production process of organic fertilizer without poultry and livestock manure, comprising the following steps:

[0032] S1: 60-80 parts by weight of edible mushroom waste packaging powder, 5-10 parts by weight of fish meal, 5-10 parts by weight of soybean meal, 1-5 parts by weight of activated carbon, 1 part by weight of -5 silicon powder, 5-10 parts by weight of tobacco stem powder, 6-15 parts by weight of humus and 0.1-0.2 parts by weight of BFA fermentation agent are uniformly mixed to form a mixed material; the carbon in the mixed material The nitrogen ratio is controlled at 25:1 to 30:1, which is convenient for the fermentation reaction of the mixed material under the action of fermentation bacteria; the silicon powder is preferably porous silicon powder, which is convenient for the reproduction of fermentation bacteria; The water and amino acids contained in the mixture are combined with the BFA starter, thereby multiplying in the porous silicon powder and activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com