Preparation method of nickel oxide and lignin carbon electrochemical catalysis nanocomposite

A technology of lignin carbon and catalytic materials, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of scarce sources, limited industrial applications, high overpotential, etc., and achieve simple and environmentally friendly preparation methods, wide sources of raw materials, and stable catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

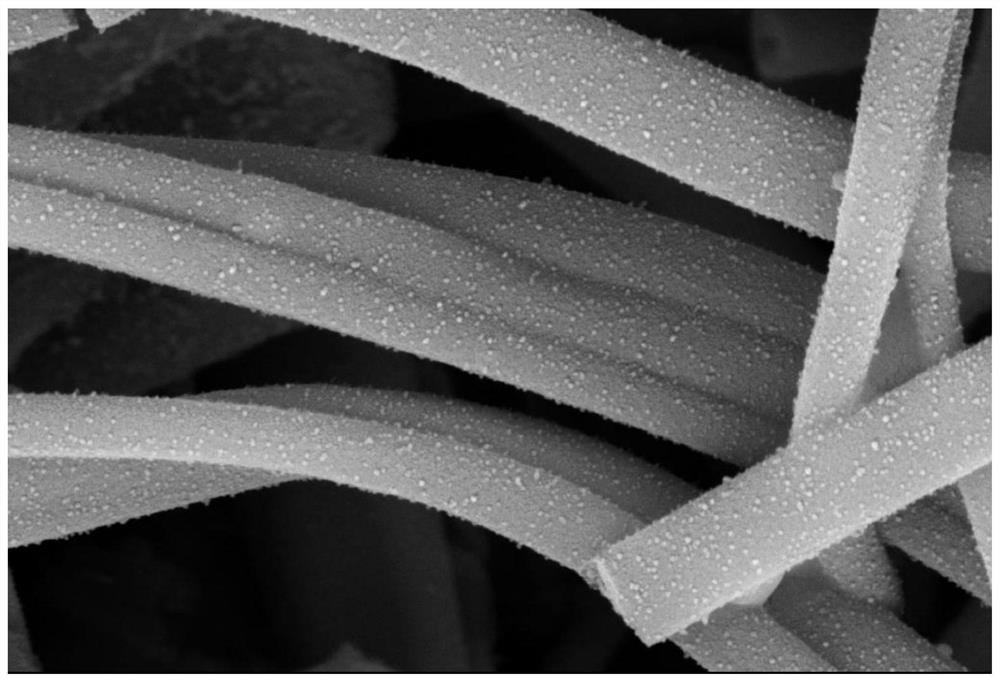

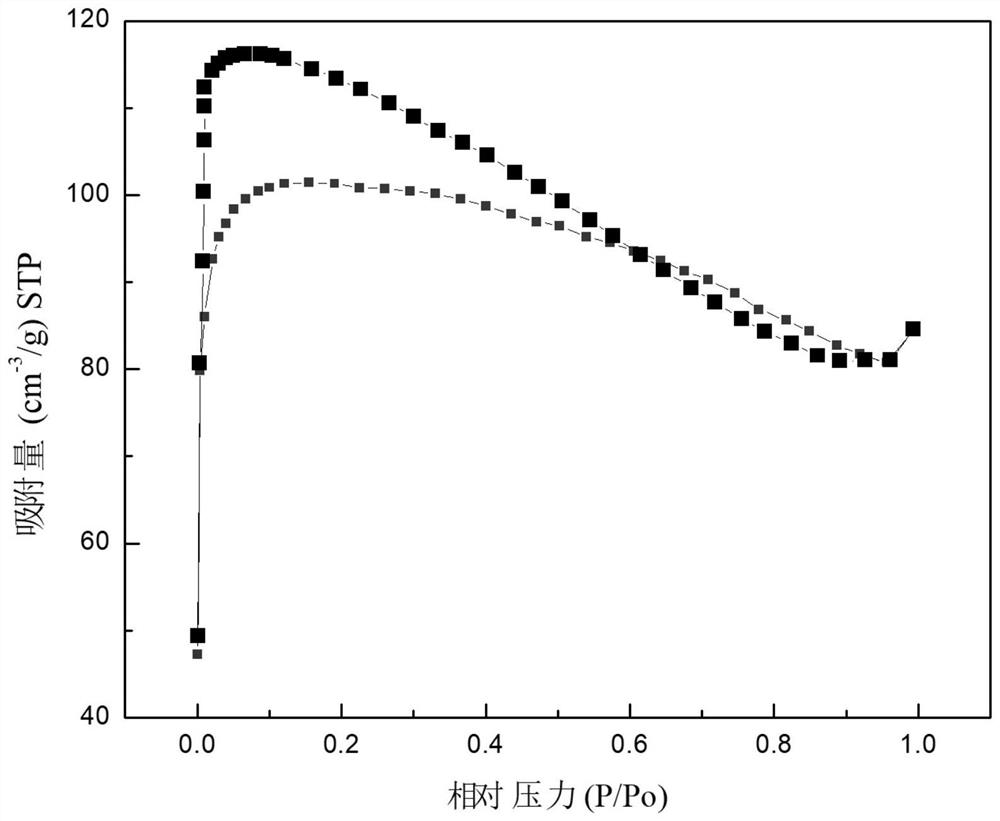

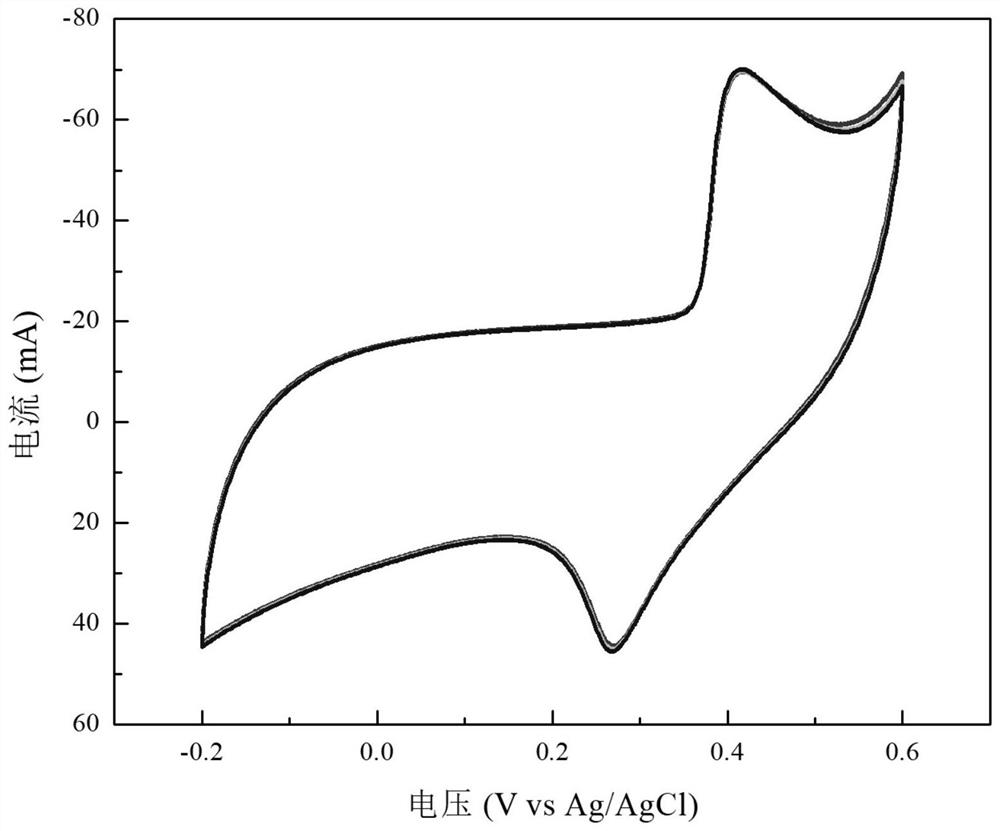

[0027] refer to Figure 1 ~ Figure 4 , a preparation method of nickel oxide / carbon composite nano-electrochemical catalytic material,

[0028] Weigh 2 g of gelatin particles, add to a mixed solution of 5 g of glacial acetic acid and 3 g of deionized water, and stir magnetically for 2 hours at room temperature. Subsequently, 10%wt sodium lignosulfonate (ie 1.11g sodium lignosulfonate) was added, and magnetically stirred at room temperature for 6 hours until uniform. Subsequently, after adding 0.25 g of nickel nitrate hexahydrate, the stirring was continued until uniform. Next, the homogeneous solution was poured into a disposable syringe for electrospinning. The obtained spinning product was ground with a mortar, and then placed in a vacuum oven at 60° C. for 24 hours to vacuum dry. The dried product was put into a tube furnace, calcined in an argon atmosphere at 800° C. for 150 minutes, cooled and ground to obtain nanocomposite fibers.

[0029] Electrode preparation: Add 0...

Embodiment 2

[0031] 2 g of gelatin particles were weighed, added to a mixed solution of 10 g of glacial acetic acid and 8 g of deionized water, and magnetically stirred at room temperature for 3 hours. Subsequently, 20%wt sodium lignosulfonate (ie 5g sodium lignosulfonate) was added, and magnetically stirred at room temperature for 8 hours until uniform. Subsequently, after adding 0.25 g of nickel nitrate hexahydrate, the stirring was continued until uniform. Next, the homogeneous solution was poured into a disposable syringe for electrospinning. The obtained spinning product was ground with a mortar, and placed in a vacuum oven at 80° C. for 48 hours to vacuum dry. The dried product was put into a tube furnace, calcined in an argon atmosphere at 1000° C. for 180 minutes, cooled and ground to obtain nanocomposite fibers.

[0032] Electrode preparation was consistent with the above examples.

Embodiment 3

[0034] 2 g of gelatin particles were weighed, added to a mixed solution of 10 g of glacial acetic acid and 4 g of deionized water, and magnetically stirred at room temperature for 2.5 hours. Subsequently, 20%wt sodium lignosulfonate (ie 4g sodium lignosulfonate) was added, and magnetically stirred at room temperature for 7 hours until uniform. Subsequently, after adding 0.25 g of nickel nitrate hexahydrate, the stirring was continued until uniform. Next, the homogeneous solution was poured into a disposable syringe for electrospinning. The obtained spinning product was ground with a mortar, and placed in a vacuum oven at 70° C. for 24 hours to vacuum dry. The dried product was put into a tube furnace, calcined in an argon atmosphere at 900° C. for 120 minutes, cooled and ground to obtain nanocomposite fibers.

[0035] Electrode preparation was consistent with the above examples.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap