Modified ethylene-methyl acrylate copolymer as well as preparation method and application thereof

A technology of methyl acrylate and copolymer, applied in the field of modified ethylene-methyl acrylate copolymer and its preparation, can solve the adjustment of the preparation process of ethylene-methyl acrylate copolymer, the difference and influence of product molecular weight and branching situation The grafting or composite process is effectively carried out to achieve excellent mechanical properties and corrosion resistance, high melting point, and the effect of increasing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of modified ethylene-methyl acrylate copolymer, comprises the steps:

[0030] S1, preparation of nickel complex catalyst;

[0031] S2. Under the action of the nickel complex catalyst obtained in step S1, copolymerize ethylene and methyl acrylate to obtain an ethylene-methyl acrylate copolymer;

[0032] S3. Melt blend the ethylene-methyl acrylate copolymer obtained in step S2 with vinyltrimethoxysilane and di-tert-butyl peroxide according to the first preset mass ratio, and obtain mixture A after drying; Silica nanoparticles are dispersed in the first solvent, and then a predetermined amount of vinyltrimethoxysilane and ammonium persulfate are added to obtain mixture B after fully reacting; then the mixture A, mixture B and dodecylbenzene The sodium sulfonate is melt-blended according to the second preset mass ratio, and the product is placed in water to fully react, taken out and dried to obtain a modified ethylene-me...

Embodiment 1

[0045] The present embodiment provides a kind of preparation method of modified ethylene-methyl acrylate copolymer, comprises the steps:

[0046] S1, preparation of nickel complex catalyst

[0047] Dissolve aniline in dichloromethane, then add trimethyl phosphite and elemental iodine, control the molar ratio of aniline, trimethyl phosphite and iodine to 5:2:1, fully stir the reaction for 10h, then add hydrochloric acid (12mol / L), adding sodium bicarbonate solution and sodium chloride solution successively for extraction to obtain an extraction product; spin-drying the extraction product and dissolving it in tetrahydrofuran, adding n-butyllithium dropwise at 0°C, and fully reacting for 2 hours, Add chlorobis (2-methoxyphenyl) phosphine again, control the mol ratio of extract product, n-butyllithium and chlorobis (2-methoxyphenyl) phosphine to be 1:1:1, after sufficient reaction 10h, to The obtained organic phase is sequentially extracted, concentrated and recrystallized to ob...

Embodiment 2~11 and comparative example 1~3

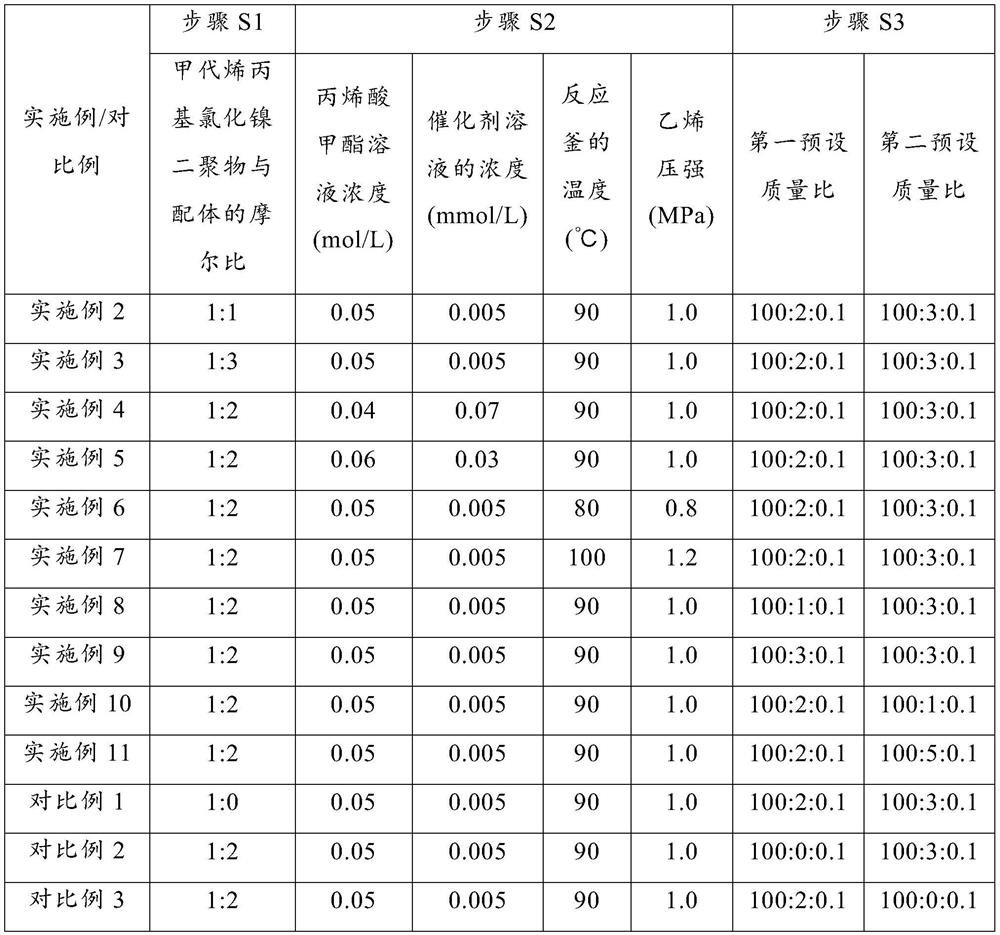

[0069] Embodiment 2~11 and comparative example 1~3 respectively provide a kind of preparation method of modified ethylene-methyl acrylate copolymer, compared with embodiment 1, the difference is that the corresponding process parameter in each step is changed, The corresponding parameter values of each embodiment and comparative example are shown in Table 1, and the remaining steps and parameters are consistent with those of Embodiment 1, and will not be repeated here.

[0070] Table 1 embodiment 2~11 and the process parameter of comparative example 1~3

[0071]

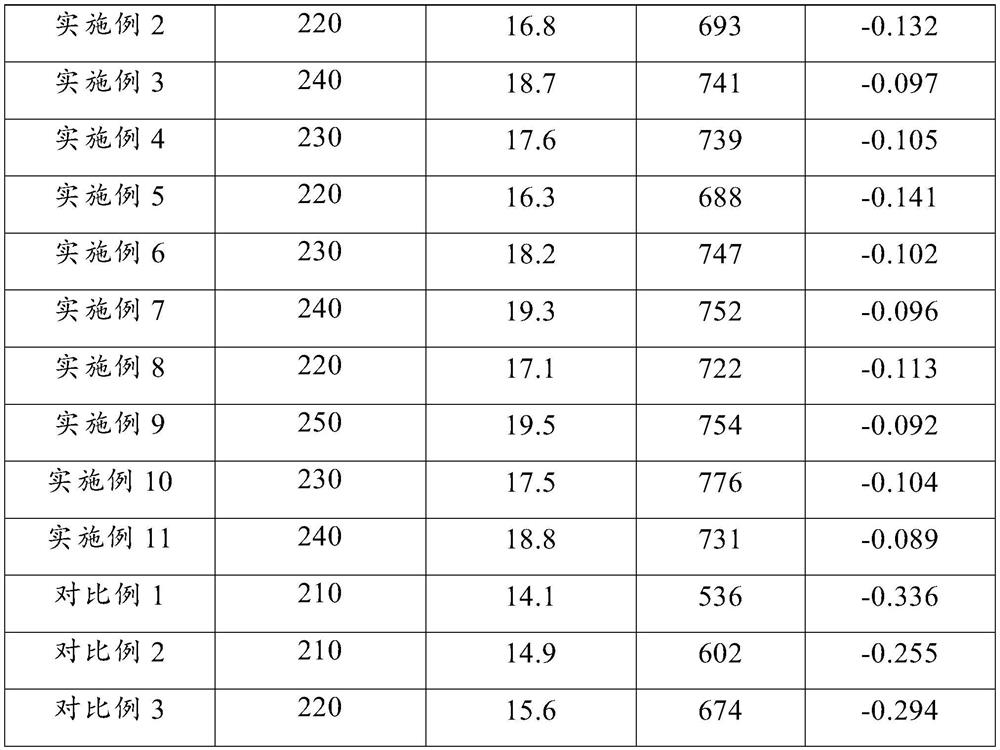

[0072] The properties of the modified ethylene-methyl acrylate copolymers prepared in Examples 2-11 and Comparative Examples 1-3 were tested, and the results are shown in Table 2.

[0073] The performance of the modified ethylene-methyl acrylate copolymer prepared by Table 2 embodiment 2~11 and comparative examples 1~3

[0074]

[0075]

[0076] As can be seen from Table 2, the adjustment of process paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com