Phosphorus-doped vanadium pentoxide/vanadium heptaoxide porous nanofiber as well as preparation method and application thereof

A technology of vanadium pentoxide and vanadium heptaoxide, applied in the field of electrochemical energy storage, can solve the problems of poor rate performance, unfavorable commercial development, small specific capacity, etc., achieve good rate performance, improve cycle stability, increase The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing high-performance phosphorus-doped vanadium pentoxide / vanadium heptoxide porous nanofibers, comprising the following steps:

[0035] 1) Weigh 1 g of vanadyl acetylacetonate and 2 g of polyvinyl pyrrolidone and dissolve them in 9.49 g of N-N dimethylformamide solvent, and stir at room temperature for 12 hours.

[0036] 2) Weigh 0.0259 g of phosphoric acid and dissolve it in step 1) and continue to stir the solution for 12 hours until the mixture is evenly mixed to obtain the electrospinning precursor solution.

[0037]3) The electrospinning precursor solution was added into the syringe needle, and the electrospinning was performed at a voltage of 13kV, a distance between the needle and the roller of 13cm, and a bolus injection speed of 0.8mL / h to obtain a spinning product.

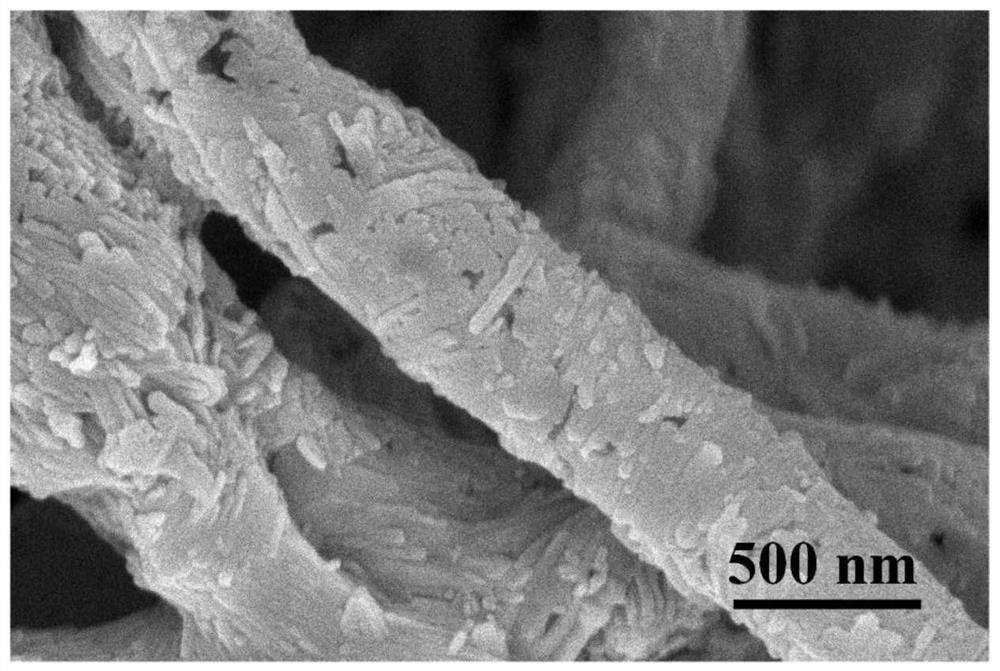

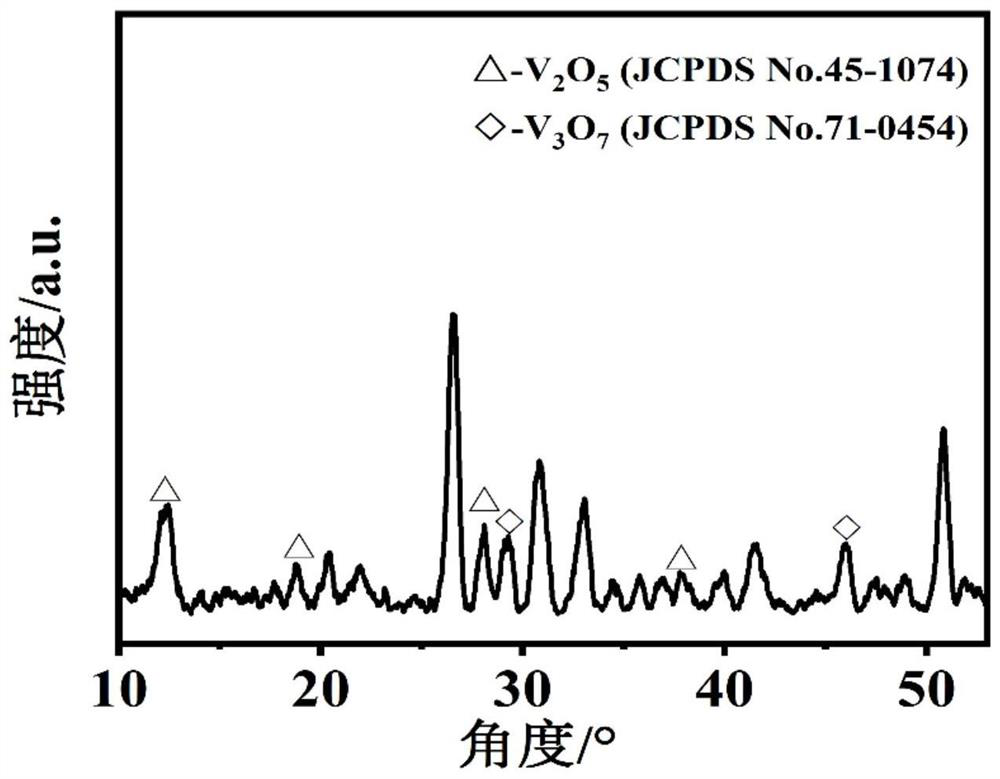

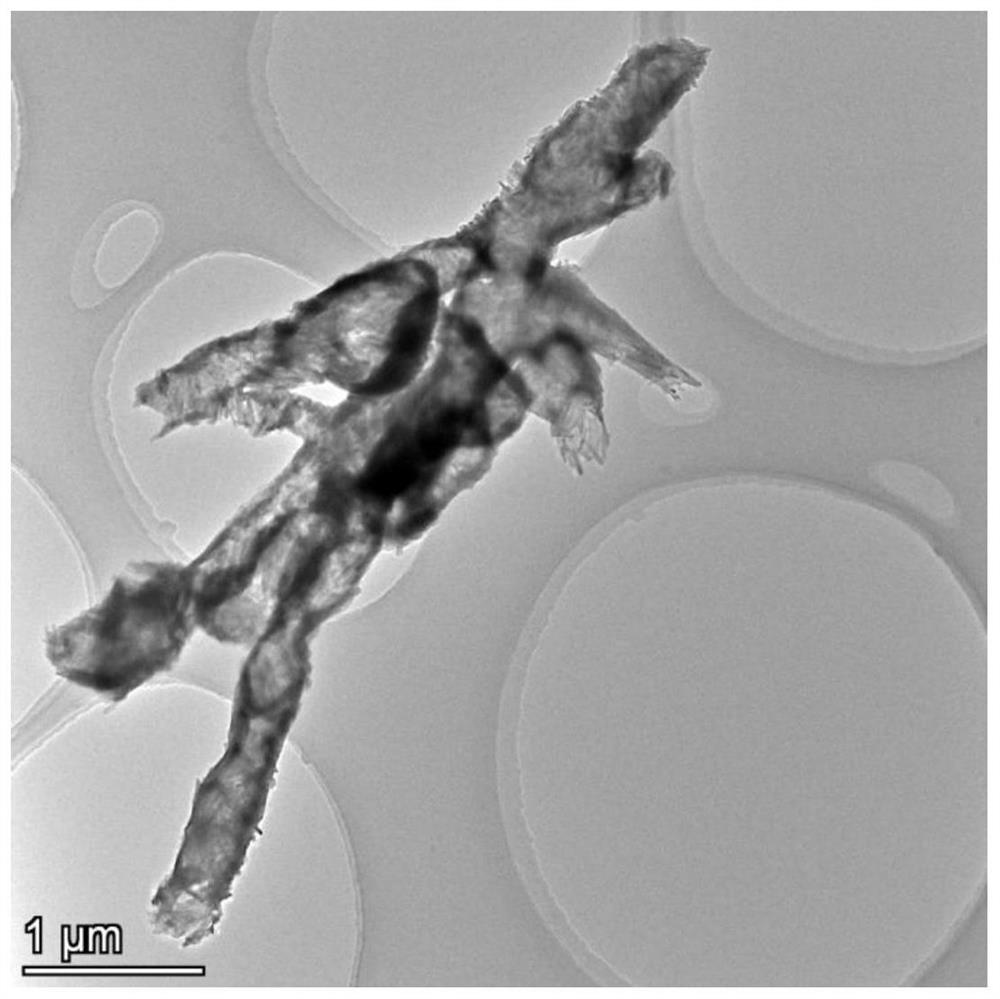

[0038] 4) Calcining the electrospun product obtained in step 3) at 200°C for 2 hours in an air atmosphere to obtain phosphorus-doped V 2 o 5 / V 3 o 7 Porous nanofibers, name...

Embodiment 2

[0047] A method for preparing high-performance phosphorus-doped vanadium pentoxide / vanadium heptoxide porous nanofibers, comprising the following steps:

[0048] 1) Weigh 1 g of vanadyl acetylacetonate and 3 g of polyvinyl pyrrolidone and dissolve them in 18.98 g of N-N dimethylformamide solvent, and stir at room temperature for 10 h.

[0049] 2) Weigh 0.0518 g of phosphoric acid and dissolve it in step 1) and continue to stir the solution for 10 h until the mixture is uniform to obtain the electrospinning precursor solution.

[0050] 3) Add the electrospinning precursor solution into the syringe needle, and perform electrospinning at a voltage of 14kV, a distance between the needle and the roller of 14cm, and a bolus injection speed of 0.9mL / h.

[0051] 4) Calcining the electrospun product obtained in step 3) at 300°C for 3 hours in an air atmosphere to obtain phosphorus-doped V 2 o 5 / V 3 o 7 Porous nanofibers, namely PVO porous nanofibers.

[0052] In order to verify t...

Embodiment 3

[0055] A method for preparing high-performance phosphorus-doped vanadium pentoxide / vanadium heptoxide porous nanofibers, comprising the following steps:

[0056] 1) Dissolve 1 g of vanadyl acetylacetonate and 3 g of polyvinylpyrrolidone in 28.47 mL of N-N dimethylformamide solvent, respectively, and stir at room temperature for 8 h.

[0057] 2) Weigh 0.0777g of phosphoric acid and dissolve it in step 1), and continue to stir the solution for 8 hours until the mixture is uniform, so as to obtain the electrospinning precursor solution.

[0058] 3) Add the electrospinning precursor solution into the syringe needle, and perform electrospinning at a voltage of 15kV, a distance between the needle and the roller of 15cm, and a bolus injection speed of 1mL / h to obtain a spinning product.

[0059] 4) Calcining the electrospun product obtained in step 3) at 400°C for 4 hours in an air atmosphere to obtain phosphorus-doped V 2 o 5 / V 3 o 7 Porous nanofibers, namely PVO porous nanofib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com