Preparation method of 4D printing NiTi alloy EBSD sample polishing solution, product and application thereof

A polishing solution and sample technology, which is applied in the field of preparation of 4D printing NiTi alloy EBSD sample polishing solution, can solve the problems of difficulty in obtaining electrolyte formula and electrolysis parameters, inability to remove the surface stress of printed samples, and long mechanical polishing and polishing time, etc., to achieve Good polishing effect, low surface roughness, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

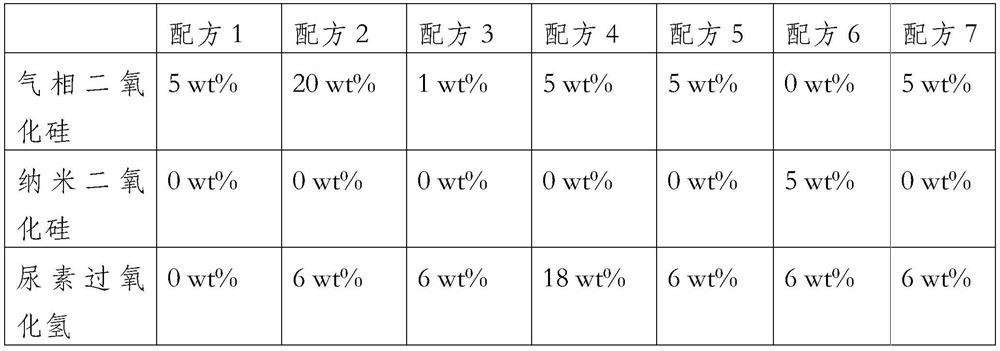

Examples

Embodiment 1

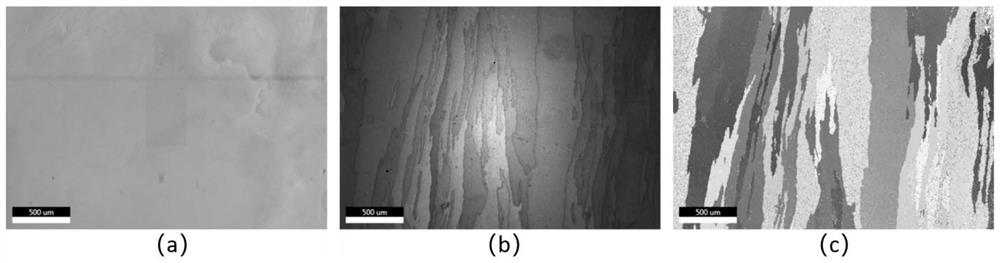

[0036] Alloy 4D prints NiTi alloy, and prepares EBSD samples according to the following steps.

[0037] (1) Cutting: The 4D printed NiTi alloy samples were cut by wire cutting method. In this embodiment, the 4D printed NiTi alloy to be cut is fixed on a wire cutting machine, and cut along the section to be analyzed, and the thickness of the 4D printed NiTi alloy sample is 1 mm.

[0038] (2) Cleaning: Use acetone solution to clean the cut samples to remove metal powder and oil stains remaining on the surface during the cutting process.

[0039] (3) Inlay: use CMR2 to inlay the cut sample, and the thickness after inlay is 12mm.

[0040] (4) Grinding: Use 400#, 1200# diamond grinding discs and 2000#, 3000#, 5000# silicon carbide sandpaper to grind the surface of the 4D printed NiTi alloy sample under water cooling until no scratches are observed with the naked eye. In this embodiment, a grinding and polishing machine is used to grind the sample, and water is continuously added ...

Embodiment 2

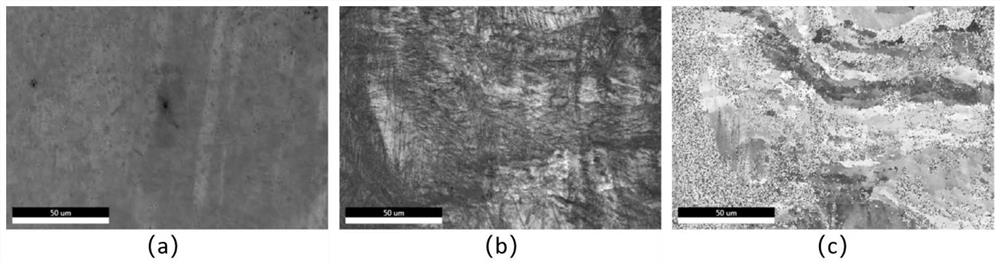

[0047] Experimental Alloy 4D printing NiTi alloy, EBSD samples were prepared according to the following steps.

[0048] (1) Cutting: The 4D printed NiTi alloy samples were cut by wire cutting method. In this embodiment, the 4D printed NiTi alloy to be cut is fixed on a wire cutting machine tool, and cut along the section to be analyzed, and the thickness of the 4D printed NiTi alloy sample is 1-2 mm.

[0049] (2) Cleaning: Use acetone solution to clean the cut samples to remove metal powder and oil stains remaining on the surface during the cutting process.

[0050] (3) Inlay: use CMR2 to inlay the cut sample, and the thickness after inlay is 11mm.

[0051] (4) Grinding: Use 400#, 1200# diamond grinding discs and 2000#, 3000#, 5000# silicon carbide sandpaper to grind the surface of the 4D printed NiTi alloy sample under water cooling until no scratches are observed with the naked eye. In this embodiment, a grinding and polishing machine is used to grind the sample, and water...

Embodiment 3

[0058] Alloy 4D prints NiTi alloy, and prepares EBSD samples according to the following steps.

[0059] (1) Cutting: The 4D printed NiTi alloy samples were cut by wire cutting method. In this embodiment, the 4D printed NiTi alloy to be cut is fixed on a wire cutting machine tool, and cut along the section to be analyzed, and the thickness of the 4D printed NiTi alloy sample is 1-2 mm.

[0060] (2) Cleaning: Use acetone solution to clean the cut samples to remove metal powder and oil stains remaining on the surface during the cutting process.

[0061] (3) Inlay: use CMR2 to inlay the cut sample, and the thickness after inlay is 12mm.

[0062] (4) Grinding: Use 400#, 1200# diamond grinding discs and 2000#, 3000#, 5000# silicon carbide sandpaper to grind the surface of the 4D printed NiTi alloy sample under water cooling until no scratches are observed with the naked eye. In this embodiment, a grinding and polishing machine is used to grind the sample, and water is continuously...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com