High-temperature binding agent of aluminum phosphosilicate and preparation method of high-temperature binding agent

A high-temperature binder, aluminum phosphosilicate technology, applied in the direction of polymer binder additives, non-polymer binder additives, adhesives, etc. Low temperature and high curing conditions, to achieve the effects of good thermal shock stability, small high temperature creep value and uniform expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the aluminum dihydrogen phosphate is as follows: adjust the aluminum hydroxide powder into a slurry, then add phosphoric acid, and react until transparent at 20-120°C and 20-500r / min, to obtain the phosphoric acid dihydrogen phosphate. Aluminum hydrogen phosphate; specifically, aluminum dihydrogen phosphate refers to an aqueous solution of aluminum dihydrogen phosphate. When preparing aluminum dihydrogen phosphate, the amount of aluminum hydroxide added in each part of phosphoric acid is 0.22 parts, and the amount of water added is 2.5 parts.

[0027] In the following examples, the impact strength was tested according to the provisions of GB / T1732-93; the flexibility was tested according to the provisions of GB / T1731-1993, and the bond strength was tested according to the provisions of GB / T31541-2019.

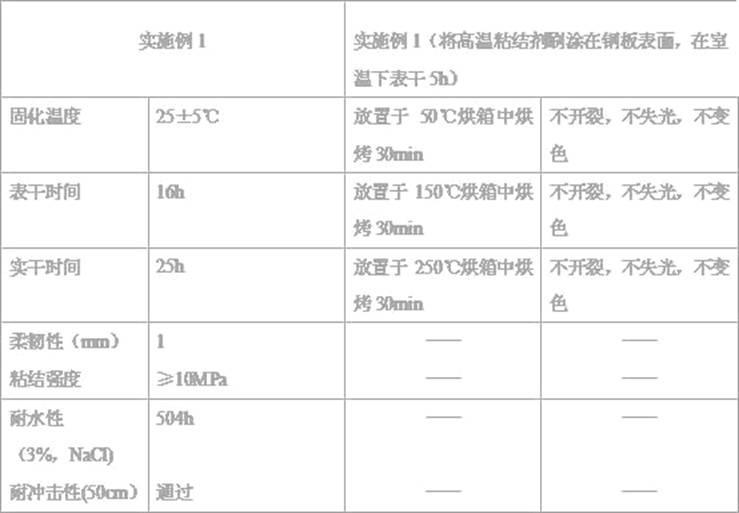

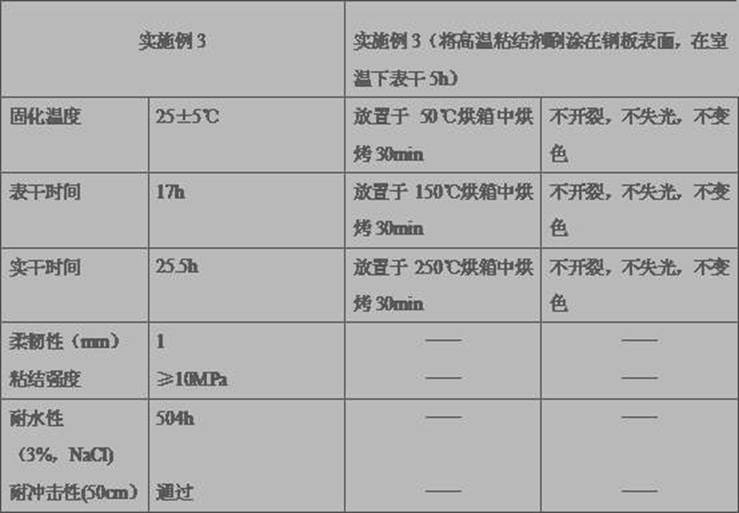

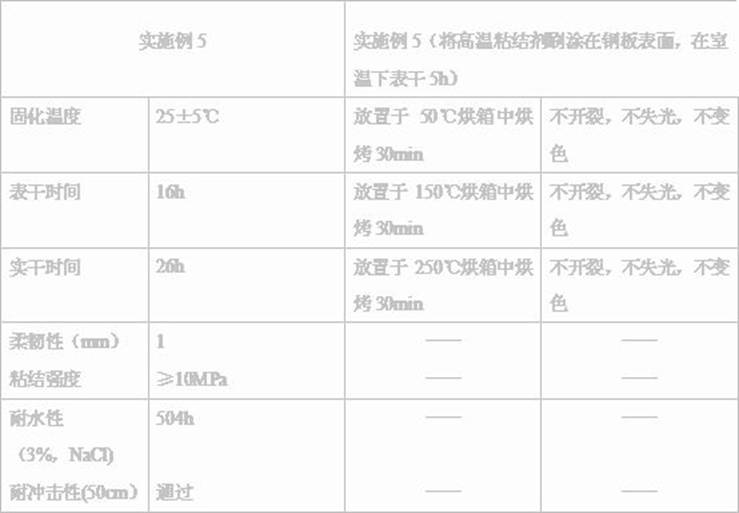

Embodiment 1

[0029] A high-temperature binder for aluminum phosphosilicate, which consists of the following components in parts by weight: 44 parts of aluminum dihydrogen phosphate, 7 parts of zinc silicate, 36 parts of manganese oxide, 11 parts of phosphoric acid, 0.05 part of natural silica, 0.05 part of polyvinyl alcohol, 0.06 part of kaolin, 0.001 part of thickener;

[0030] A preparation method of a high-temperature binder of aluminum phosphosilicate, comprising the following steps:

[0031] (1) Weighing and mixing the raw materials for the high-temperature binder of aluminum phosphosilicate according to the formula to obtain the mixed raw materials;

[0032] (2) Disperse the mixed raw material at high speed for 0.5h under the condition of 300r / min, and then disperse the mixed raw material at high speed for 0.5h under the condition of 500r / min to obtain the high-temperature binder of aluminum phosphosilicate.

[0033] The application of the high-temperature binder of aluminum phospho...

Embodiment 2

[0037] A high-temperature binder for aluminum phosphosilicate, the high-temperature binder for aluminum phosphosilicate is composed of the following components by weight: 45 parts of aluminum dihydrogen phosphate, 5 parts of lithium silicate, metal and / or metal 40 parts of oxides, 10 parts of phosphoric acid, 0.1 parts of fumed silica, 0.01 parts of polyvinyl alcohol, 0.05 parts of bentonite, 0.004 parts of additives;

[0038] The metal and / or metal oxide includes 35 parts by weight of alumina, 5 parts by weight of zirconia, a total of 40 parts by weight;

[0039] The auxiliary agent includes 0.001 parts by weight of dispersant, 0.001 parts by weight of defoamer, 0.002 parts by weight of silane coupling agent, a total of 0.004 parts by weight;

[0040] A preparation method of a high-temperature binder of aluminum phosphosilicate, comprising the following steps:

[0041](1) Weighing and mixing the raw materials for the high-temperature binder of aluminum phosphosilicate accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com