Method for recovering polyimide by selectively breaking imide bond

A polyimide and imide technology, which is applied in the field of recycling and recycling of waste polymer materials, can solve problems such as unfavorable industrialization, high pressure, and complex degradation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, a method for selectively breaking imide bonds to reclaim polyimide comprises the following steps:

[0035] Mix water and m-cresol in a mass ratio of 1:1 to form a mixed solution, prepare the mixed solution and LiOH at a catalyst mass fraction of 20% to form a reaction system I, and mix the polyimide material and reaction system I in a mass ratio of 1:1 Mixed and added to the reactor, sealed and placed in a homogeneous reactor heated to 220 ° C, reacted for 7h. After the reaction is completed, cool to room temperature, filter, add deionized water to wash the filter cake to obtain 4,4'-diaminodiphenyl ether; distill off the organic solvent in the filtrate, add hydrochloric acid to precipitate aromatic phthalic acid, filter and dry After that, pyromellitic acid was obtained.

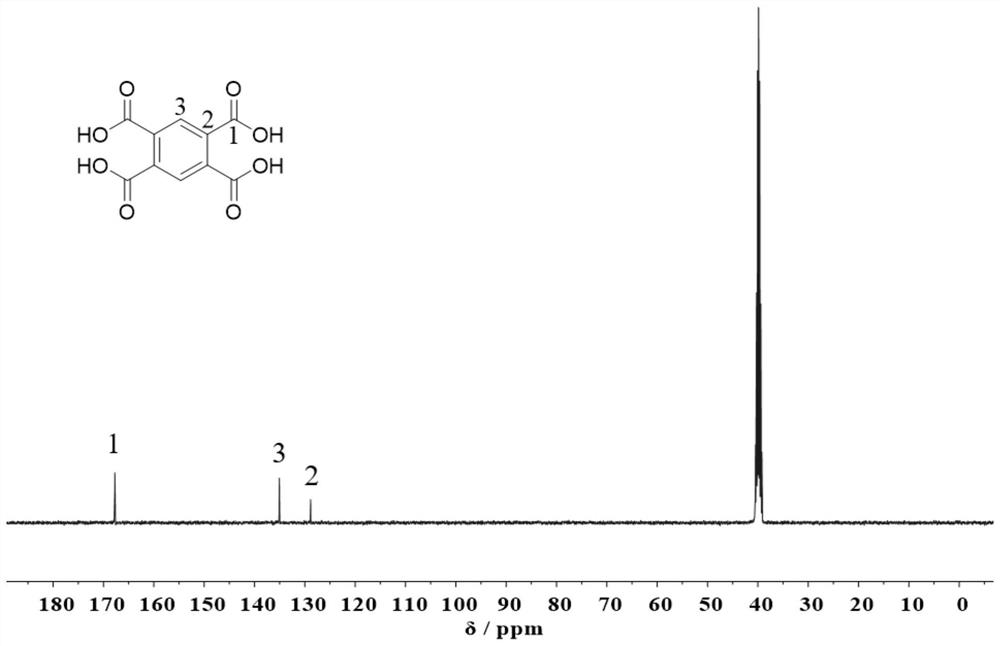

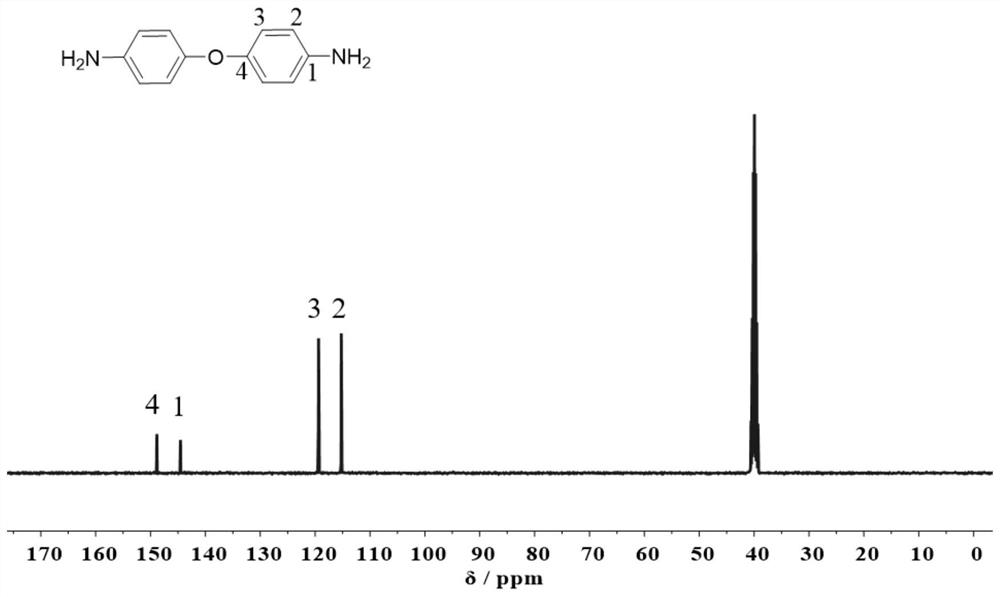

[0036] figure 1 It is the carbon nuclear magnetic resonance spectrum of the pyromellitic acid monomer recovered; figure 2 It is the carbon nuclear magnetic resonance sp...

Embodiment 2

[0038] In the present embodiment, a method for selectively breaking imide bonds to reclaim polyimide comprises the following steps:

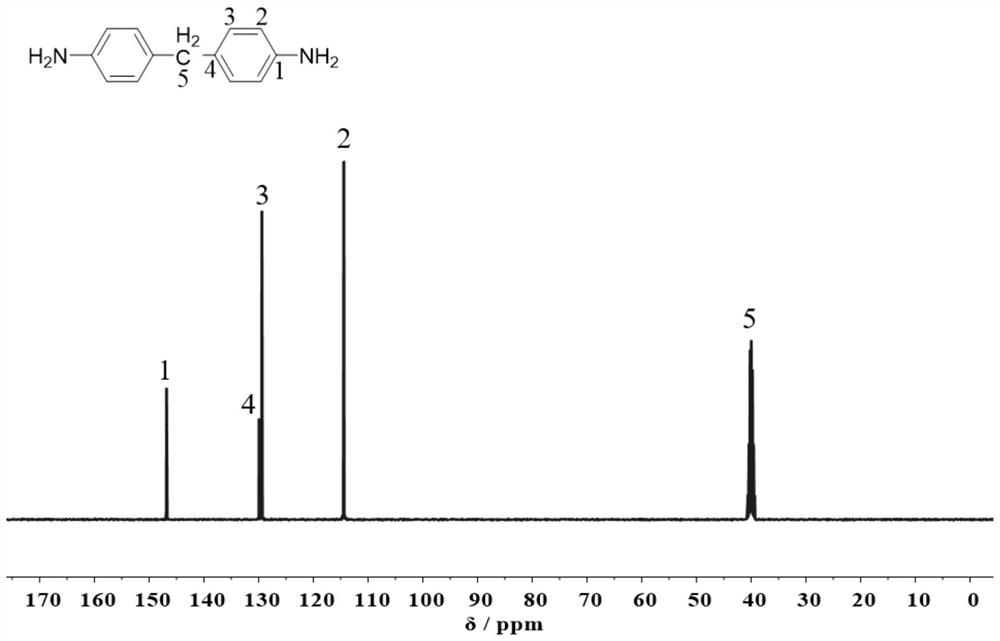

[0039] Water and N,N'-dimethylacetamide are formulated into a mixed solution at a mass ratio of 1:5, and the mixed solution and (CH 3 ) 4 NOH is formulated into reaction system Ⅰ according to the catalyst mass fraction of 30%. Mix the polyimide material and reaction system Ⅰ according to the mass ratio of 1:10 and add it to the reaction kettle. After sealing, place it in a homogeneous reactor and heat it to 110°C for 6 hours. . After the reaction is completed, cool to room temperature, filter, add deionized water to wash the filter cake, and obtain 4,4'-diaminodiphenylmethane, whose carbon nuclear magnetic resonance spectrum is shown in image 3 ; Evaporate the organic solvent in the filtrate, add hydrochloric acid to precipitate the aromatic phthalic acid, and obtain pyromellitic acid after filtering and drying.

Embodiment 3

[0041] In the present embodiment, a method for selectively breaking imide bonds to reclaim polyimide comprises the following steps:

[0042]Mix water and N-methylpyrrolidone at a mass ratio of 1:8 to form a mixed solution, prepare the mixed solvent and CsOH at a catalyst mass fraction of 20% to form reaction system I, and mix polyimide material and reaction system I at a mass ratio of 1 :30 mixed and added to the reactor, sealed and placed in a homogeneous reactor heated to 160 ° C, reacted for 7h. After the reaction was completed, it was cooled to room temperature, filtered, and deionized water was added to wash the filter cake to obtain p-phenylenediamine, whose carbon nuclear magnetic resonance spectrum was shown in Figure 4 ; Evaporate the organic solvent in the filtrate, add hydrochloric acid to precipitate the aromatic phthalic acid, and obtain biphenyl tetracarboxylic acid after filtration and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com