Poly (4-methyl-1-pentene) hollow fiber alloy membrane as well as preparation method and application thereof

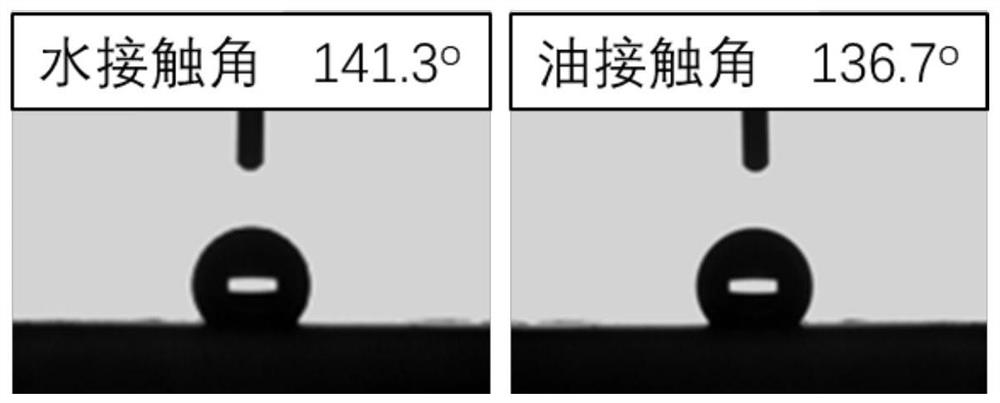

An alloy membrane and hollow technology, which is applied in the field of polyhollow fiber alloy membrane and its preparation, can solve the problems of oleophobicity and poor blood compatibility, etc., and achieve the goal of improving oleophobicity, improving blood compatibility, and the preparation method is simple and easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

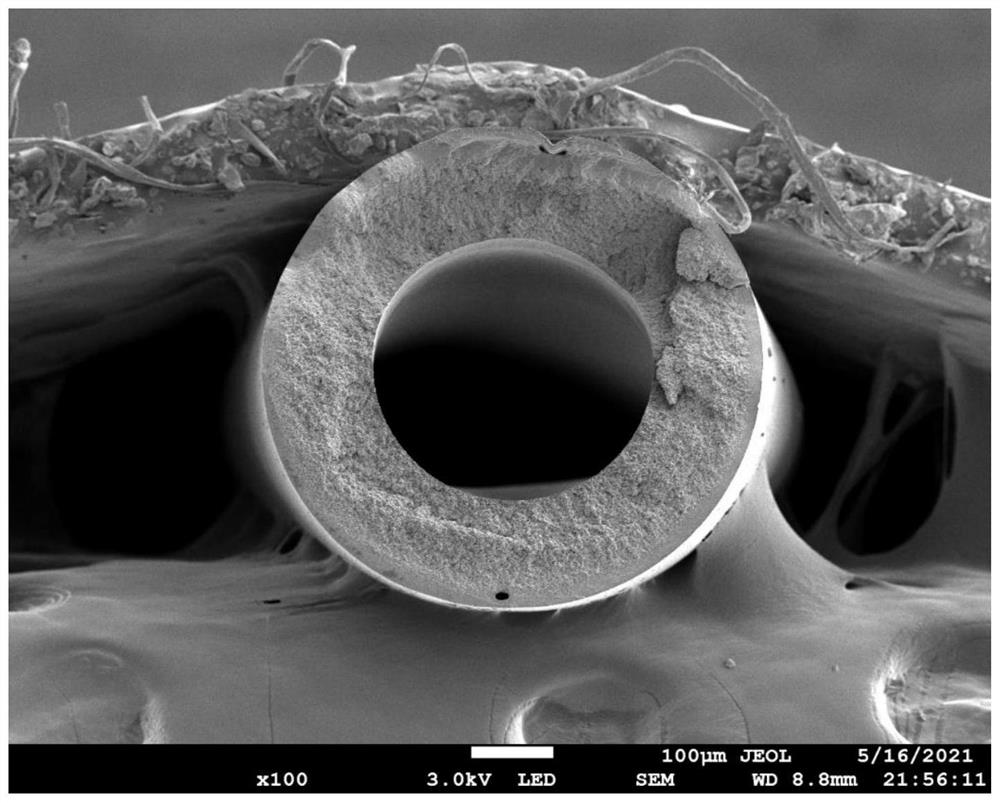

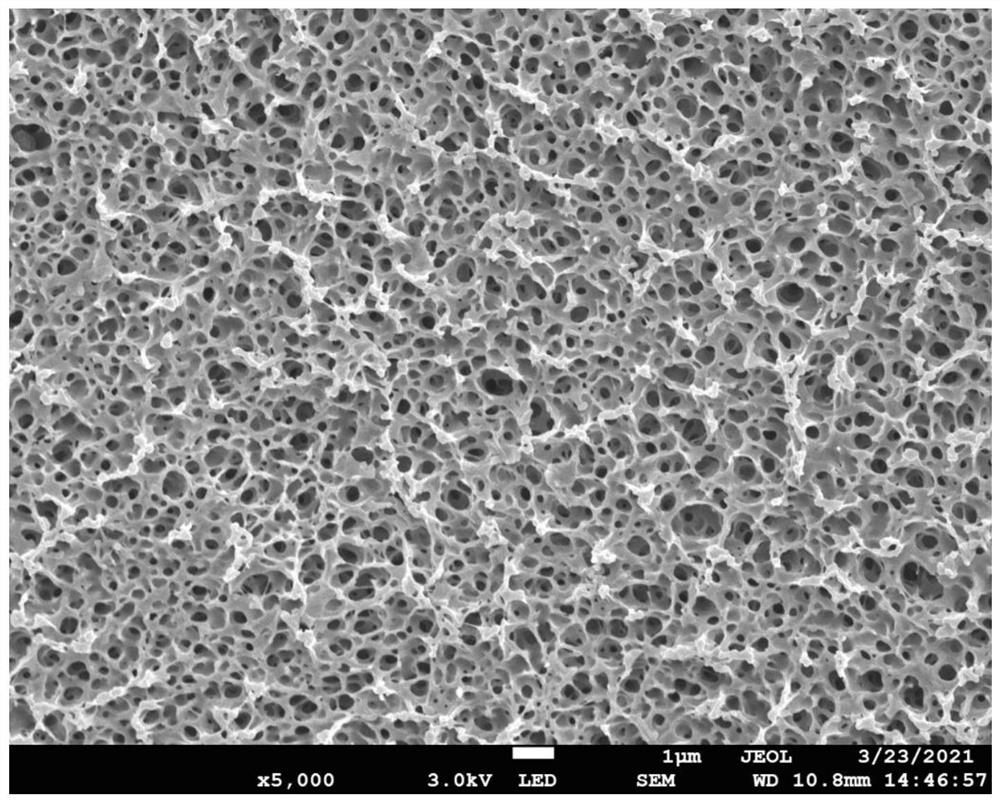

[0027] The preparation method of poly(4-methyl-1-pentene) hollow fiber alloy membrane provided by the invention comprises the following steps: (1) poly(4-methyl-1-pentene), fluoropolymer and The diluent is mixed uniformly to obtain the mixture; (2) the mixture is made into a hollow fiber; (3) the hollow fiber is solidified into a film to obtain a hollow fiber alloy membrane precursor; (4) the diluent in the hollow fiber alloy membrane precursor is removed, A poly(4-methyl-1-pentene) hollow fiber alloy membrane was obtained.

[0028] The diluent is a single-component solvent or a mixed solvent containing more than one component with a boiling point greater than 200°C, and the diluent meets the following conditions: the diluent can react with poly(4-methyl-1 -pentene) and the fluoropolymer form a homogeneous solution, and the homogeneous solution phase-separates in the temperature range of 15-50°C. Phase separation means that when the external conditions such as temperature cha...

Embodiment 1

[0038] Prepare poly(4-methyl-1-pentene) hollow fiber alloy membrane product by following method:

[0039] (1) Weigh poly(4-methyl-1-pentene) resin, ethylene-chlorotrifluoroethylene copolymer resin, hexacid and glycerol triacetate, add it into the mixer and mix uniformly to obtain the mixture, wherein The mass components in the mixture are as follows: 20wt% poly(4-methyl-1-pentene) resin, 10wt% ethylene-chlorotrifluoroethylene copolymer resin, 70wt% palmitic acid and triacetin , wherein the mass ratio of palmitic acid and glycerol triacetate is 3:1;

[0040] (2) Put the mixture in step (1) into a twin-screw extruder, melt and knead at 260°C, and extrude through a spinneret to form a hollow fiber to obtain a hollow fiber. The output speed is 80m / min;

[0041] (3) After the hollow fiber in step (2) passes through a room temperature of 25° C., it is directly cooled in a cooling bath of 40° C. for 2 seconds to realize solidification and film formation, and obtain a hollow fiber a...

Embodiment 2

[0044] Increase the mass component of poly(4-methyl-1-pentene) resin in the mixture in embodiment 1 to 29wt%, and the mass component of ethylene-chlorotrifluoroethylene copolymer resin in the mixture is reduced to 1wt% , other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Oil contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com