Multi-response core-shell structure nanogel, and preparation method and application thereof

A technology of nanogel and core-shell structure, applied in the field of multi-response core-shell structure nanogel and its preparation, can solve the problems of inability to meet long-term and stable anti-tumor treatment needs, comprehensive treatment failure, etc., to reduce drug leakage, The preparation process is simple and easy, and the raw materials are easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In order to solve the above problems, this embodiment provides a method for preparing a multi-response core-shell nanogel, which specifically includes the following steps:

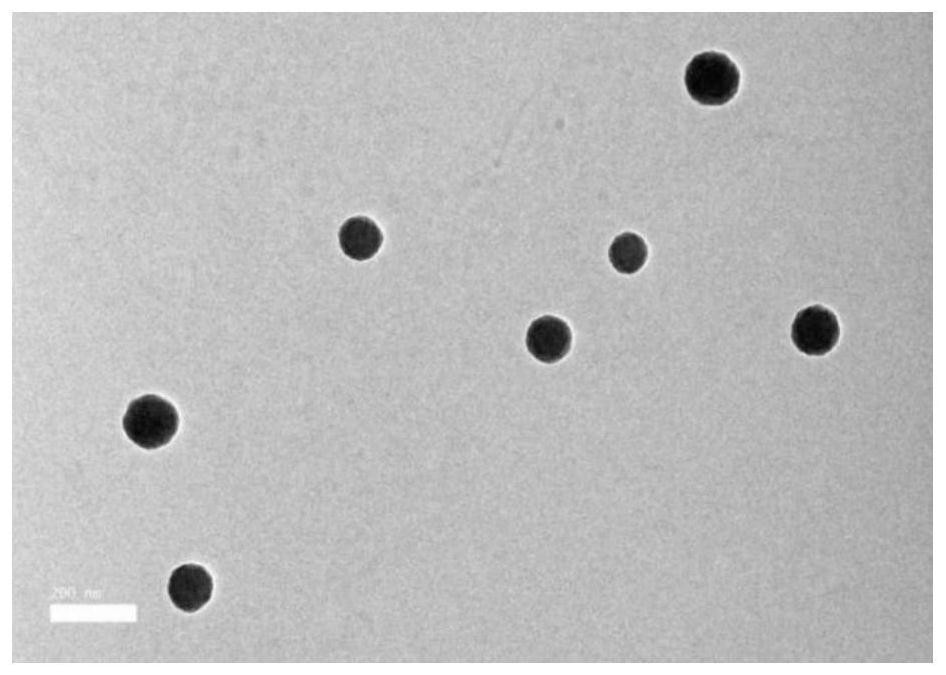

[0068] Preparation of step 1 nanogel aqueous solution: prepare P(MAA- co -NIPAM) nanogel process is as follows: 300 mg of methacrylic acid (MAA), 100 mg of N-isopropylacrylamide (NIPAM), 60 mg of crosslinker N,N'-bis(acryloyl) Cystamine (BACy) and 8 mg of initiator AIBN were dissolved in 40 mL of acetonitrile solution (monomer concentration 1.0 wt%), and sonicated for 30 min to promote their dissolution. React at 95°C for 2 h. The reaction liquid was placed in a centrifuge tube, and the solid matter was separated by ultracentrifugation (12,000 rpm, 5 min), and the obtained microspheres were separated and purified by ultrasonic cleaning three times with acetonitrile solvent. Representative nanogel P(MAA- co -NIPAM) transmission electron microscope picture as figure 1 As shown, it can be seen th...

Embodiment 2

[0070] Preparation of iron ion cross-linked nanogel core

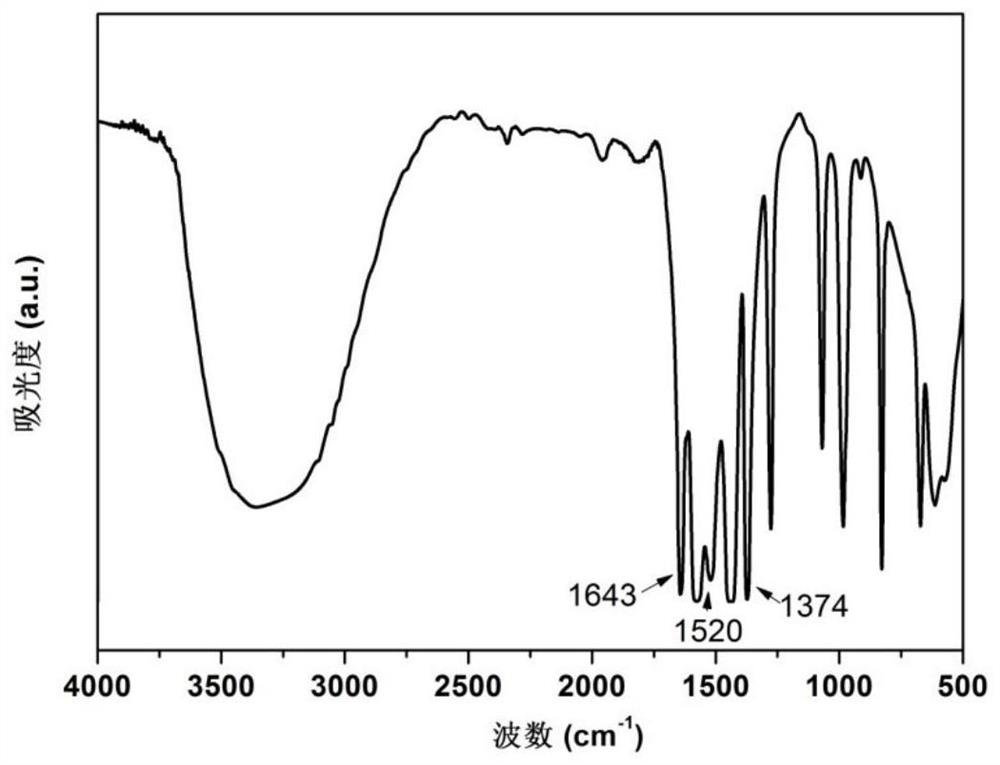

[0071] In a 100 mL round-bottomed flask, add 40 mL of acetonitrile solution, 500 mg of acrylic acid, 60 mg of iron trimethacrylate, 15 mg of AIBN (initiator), ultrasonically disperse for 10 min, heat the oil bath to 100 °C, and place in the flask Keep the reflux state with a condenser tube above, and react for 2 h. The reaction product was centrifuged (12,000 rpm, 5 min) to remove the supernatant and washed with ethanol for three times to obtain a nanogel. The Fourier transform infrared spectrum of the nanogel is shown in figure 2 shown. Of which 1643cm -1 The absorption peak at belongs to the stretching vibration absorption peak of amides. at 1520 cm -1 and 1374 cm -1 Typical metal carboxylate bands can be observed at , indicating the successful preparation of nanogels.

Embodiment 3

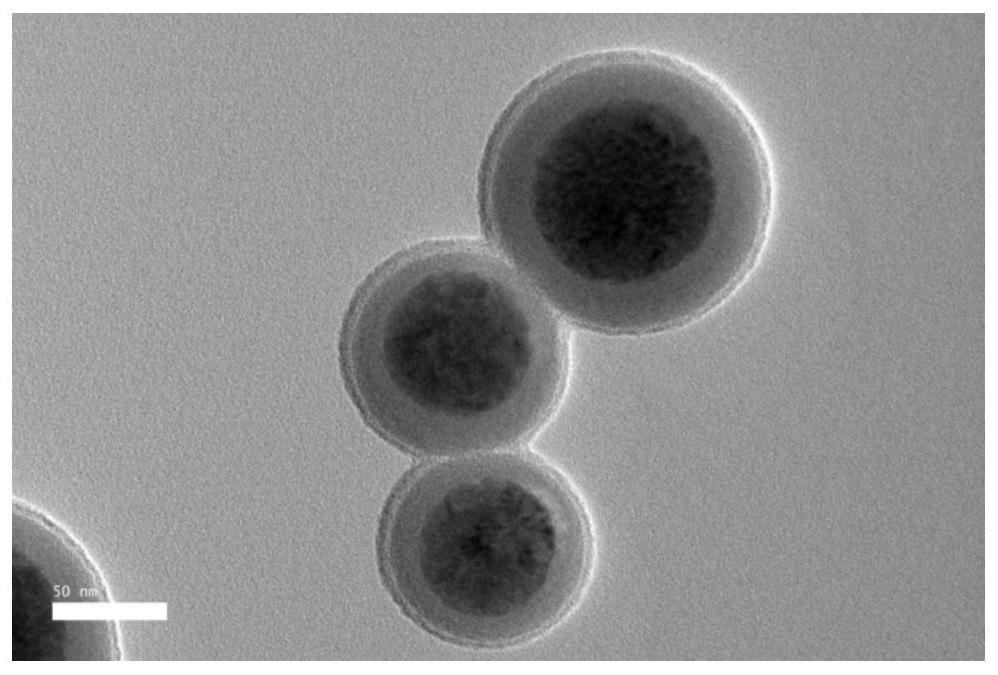

[0073] Preparation of core-shell nanogels

[0074] Chitosan-coated nanogel: Take 5 mL of the P(MAA-BACy) nanogel solution (mass concentration 50 mg / mL) prepared in Example 1 and put it in a 25 mL beaker for later use, weigh 20 mg of chitosan Dissolved in an aqueous solution of acetic acid with a concentration of 0.5-3% (more preferably 1%-2.5%, more preferably 2%), prepared into an aqueous solution of chitosan, and controlling the mass fraction of chitosan to 0.5-5wt%, more preferably It is 1.5~4wt%, more preferably 2.5wt%. At room temperature, add the chitosan aqueous solution dropwise to the nanogel aqueous solution, and the dropping time is 30-120 min, more preferably 50-100 min, more preferably 70 min. After the dropwise addition, continue to stir and react for 1-6 h (more preferably 2-5 h, more preferably 3.5 h) to separate the precipitate by high-speed centrifugation; wash repeatedly with ethanol and water several times to obtain the chitosan-coated nanogel.

[0075] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com