A zinc-nitrogen modified double-carbon catalytic material, its preparation method and its application in zinc-air batteries

A dual-carbon catalytic material and porous carbon material technology, which is applied in fuel cell half-cells and secondary battery-type half-cells, carbon preparation/purification, battery electrodes, etc., can solve the complex mixing process and complex synthesis process , high risk factor and other issues, to achieve the effect of improving ORR ability, good conductivity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

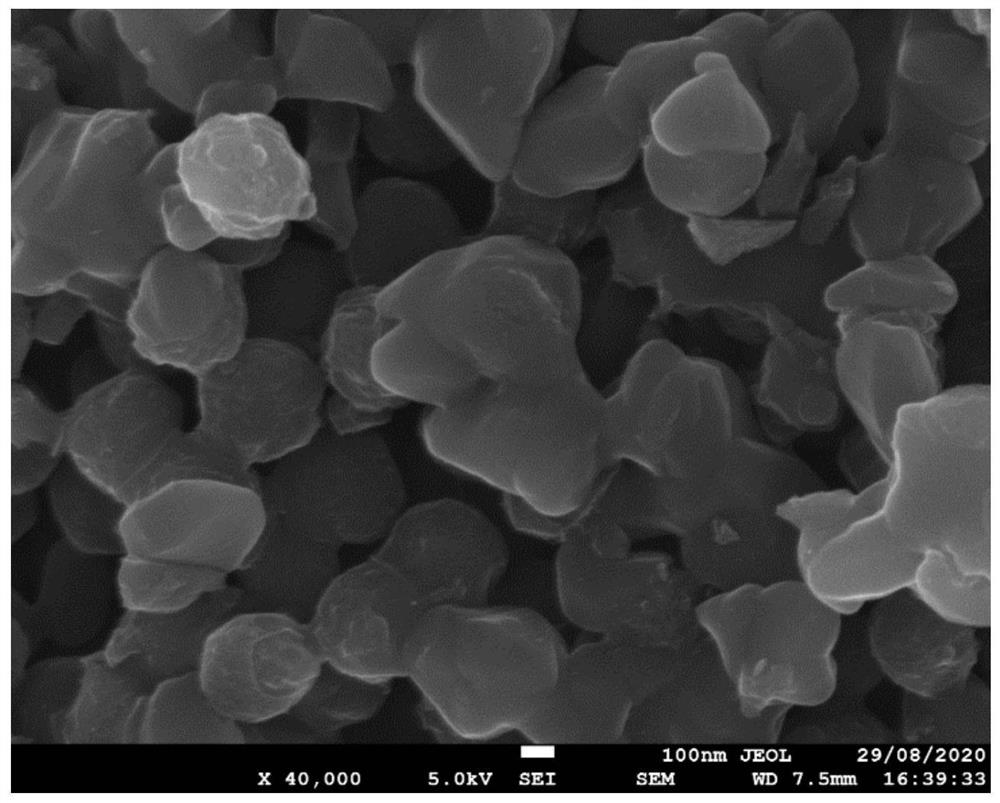

[0034] Zinc nitrate hexahydrate (1.0g) and dimethylimidazole (0.7g) were dissolved in 50mL of methanol respectively, the dissolved dimethylimidazole was poured into zinc nitrate hexahydrate, and after stirring for 5 minutes, there was a white suspension appeared, moved to 30°C for 12 h, centrifuged and washed to obtain ZIF-8. The prepared ZIF-8 was placed in a quartz boat, placed in a tube furnace, filled with argon, and heated at 5 °C for min. -1 The heating rate was increased to 900 °C, and the temperature was kept at 900 °C for 2 h, and finally cooled to room temperature naturally to obtain a black solid powder; 240r min -1 , the ball milling time is 0.5h, the mixed sample is placed in a quartz boat, placed in a tube furnace, and argon gas is introduced, and the temperature is 5 °C for min. -1 The heating rate was increased to 500 °C for annealing, and the temperature was kept at 500 °C for 5 h, followed by 5 °C min -1 The heating rate was increased to 1000 °C for anneal...

Embodiment 2

[0037] Zinc nitrate hexahydrate (1.0g) and dimethylimidazole (0.5g) were dissolved in 50mL of methanol respectively, the dissolved dimethylimidazole was poured into zinc nitrate hexahydrate, and after stirring for 5 minutes, there was a white suspension appeared, moved to 40°C for 12 h, centrifuged and washed to obtain ZIF-8. The prepared ZIF-8 was placed in a quartz boat, placed in a tube furnace, filled with argon, and heated at 3 °C for min. -1 The heating rate was increased to 700 ° C, and kept at 700 ° C for 1 h, and finally cooled to room temperature naturally to obtain a black solid powder; the powder (1 g) was mixed with dibenzyl cyanamide (0.5 g) and fructose (0.03 g), The ball mill mixing speed is 220r min -1 , the ball milling time is 1h, and the mixed sample is placed in a quartz boat, placed in a tube furnace, and heated at 3°C for min. -1 The heating rate was increased to 400 °C for annealing, and the temperature was kept at 400 °C for 5 h, followed by 3 °C m...

Embodiment 3

[0040] Zinc nitrate hexahydrate (1.0g) and dimethylimidazole (0.9g) were dissolved in 50mL of methanol respectively, the dissolved dimethylimidazole was poured into zinc nitrate hexahydrate, and after stirring for 5 minutes, there was a white suspension appeared, moved to 20°C for 12 h, centrifuged and washed to obtain ZIF-8. The prepared ZIF-8 was placed in a quartz boat, placed in a tube furnace, filled with argon, and heated at 4 °C for min. -1 The heating rate was increased to 800 °C, and the temperature was kept at 800 °C for 3 h, and finally cooled to room temperature naturally to obtain a black solid powder; this powder (1 g) was mixed with dimethyl cyanamide. (1g) and glucose (0.08g), the ball mill mixing speed is 220r min -1 , the ball milling time is 1h, and the mixed sample is placed in a quartz boat, placed in a tube furnace, and heated at 4°C for min. -1 The heating rate was increased to 650 °C for annealing, and the temperature was kept at 650 °C for 3 h, follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com