Light-resistant and anti-aging water-based acrylate coating and preparation method thereof

A water-based acrylic, anti-aging technology, applied in the direction of coating, etc., can solve the problems of easy reunion and compounding, rapid aging, poor anti-ultraviolet performance, etc., achieve good ultraviolet shielding effect, improve absorption capacity, and reduce surface drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

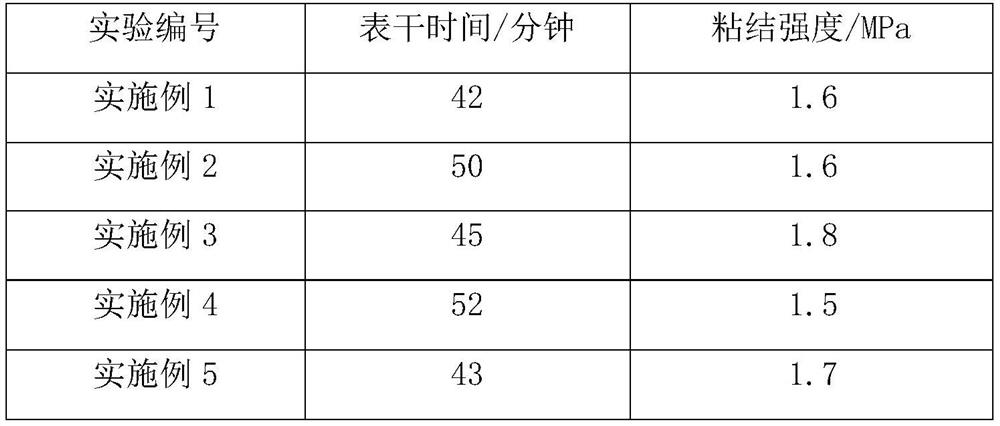

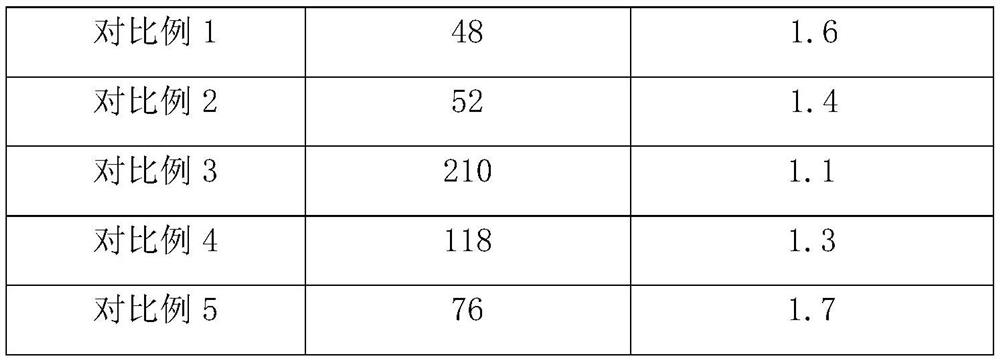

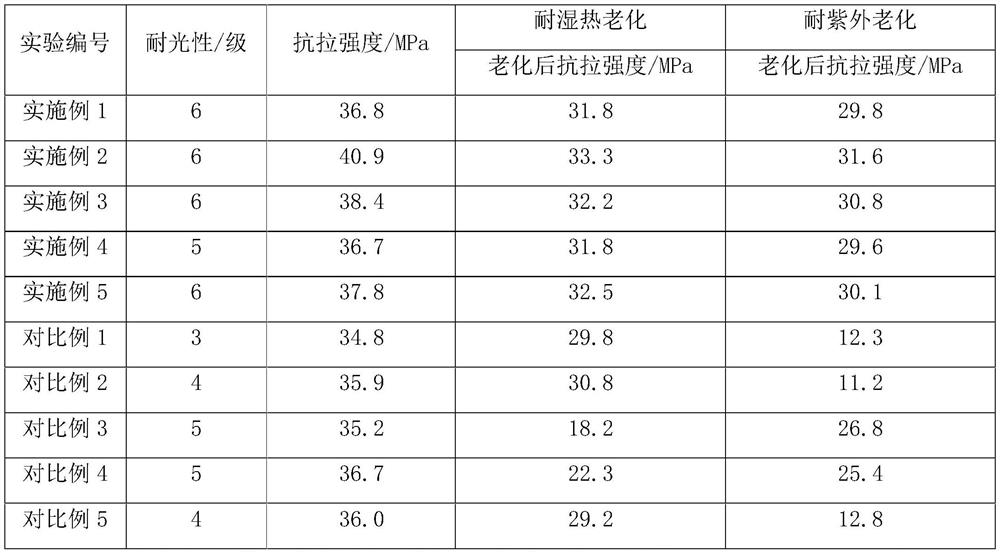

Examples

Embodiment 1

[0026] A kind of preparation method of lightfast, anti-aging water-based acrylic paint, the steps are as follows:

[0027] (1) First add 10g nano-TiO to 910g deionized water 2 and 10g nano-SiO 2 , add 10g of 3-aminopropyltriethoxysilane at room temperature and stir for 8h, then add 5g of phosphotungstic acid, continue stirring for 4h, add 40g of fatty alcohol polyoxyethylene ether and 15g of octylphenol polyoxyethylene ether, ultrasonic conditions Under emulsification for 1 hour, the composite nanoparticle emulsion modified by phosphotungstic acid was obtained;

[0028] (2) In a stirred tank, add 235g deionized water, 50g acrylic acid, 80g polymer polyol (polycarbonate diol), and stir for 30min at 40°C; after the temperature rises to 70°C, add 250g methyl methacrylate ester, 200g butyl acrylate, 50g hydroxyethyl acrylate, 20g styrene, 7g potassium persulfate was added dropwise, and the reaction was continued for 30min after the dropwise addition; 100g of the phosphotungstic ...

Embodiment 2

[0030] A preparation method of a lightfast, anti-aging water-based acrylic paint, the steps are as follows:

[0031] (1) First add 10g nano-TiO to 912g deionized water 2 and 10g nanometer ZrO 2 , add 10g of 3-aminopropyltriethoxysilane at room temperature and stir for 10h, then add 8g of silicotungstic acid, continue stirring for 5h, add 30g of fatty alcohol polyoxyethylene ether and 20g of octylphenol polyoxyethylene ether, ultrasonic conditions Emulsified for 1 hour to obtain a composite nanoparticle emulsion modified by silicotungstic acid;

[0032] (2) In the stirred tank, add 152g deionized water, 70g acrylic acid, 90g polymer polyol (polytetrahydrofuran ether glycol), and stir for 30min at 40°C; after the temperature rises to 70°C, add 300g methyl methacrylate ester, 170g butyl acrylate, 80g hydroxyethyl acrylate, 20g styrene, dropwise add 10g potassium persulfate, and continue the reaction for 30min after the dropwise addition; continue to dropwise add 100g of the sil...

Embodiment 3

[0034] A preparation method of a lightfast, anti-aging water-based acrylic paint, the steps are as follows:

[0035] (1) First add 30g nano-TiO to 830g deionized water 2 and 20g nano-Al 2 o 3 At room temperature, add 20g of 3-aminopropyltriethoxysilane and stir for 10h, then add 20g of phosphotungstic acid, continue stirring for 6h, add 60g of sodium polyacrylate and 20g of alkyl polyoxyethylene ether, and emulsify for 1h under ultrasonic conditions. Obtain the composite nanoparticle emulsion modified by phosphotungstic acid;

[0036] (2) In the stirred tank, add 120g deionized water, 80g acrylic acid, 60g polymer polyol (polytetrahydrofuran ether glycol), and stir for 30min at 40°C; after the temperature rises to 70°C, add 250g methyl methacrylate ester, 230g butyl acrylate, 100g hydroxyethyl acrylate, 40g styrene, 12g potassium persulfate was added dropwise, and the reaction was continued for 30min after the dropwise addition; 100g of the phosphotungstic acid modified com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com