Method for preparing antifouling surface from organic-inorganic hybrid particle grafted lubricating oil

An inorganic, hybrid technology, used in anti-staining/anti-fouling fibers, textiles and papermaking, fiber processing, etc., can solve problems such as reduced service life of substrates, poor lubricating oil fluidity, and reduced structural strength, to avoid Swelling, improving stability, avoiding the effect of the use of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A method for preparing organic-inorganic hybrid core-shell particles, comprising the steps of:

[0071] (1) Measure 100mL of absolute ethanol, 30mL of deionized water, and 6mL of tetraethyl orthosilicate into a 250mL flask, fix it in a 30°C oil bath, stir at 200r / min for 30min to mix the liquid evenly ;Measure 6mL of ammonia water and slowly drop into the system to react for 2h, then slowly add 3mL of vinyltriethoxysilane dropwise, and continue to react for 6h; after the reaction, repeat centrifugation and anhydrous ethanol washing for 3 times; Drying to obtain vinyl-modified silica particles (V-SiO 2 );

[0072] (2) Accurately weigh 1g V-SiO 2 , 0.5g of polyvinylpyrrolidone K30, 0.15g of azobisisobutyronitrile were dispersed in 20mL of methanol, then 1g of styrene and 0.4g of divinylbenzene were added and reacted in an oil bath at 70°C and 200r / min for 1h; Then add 0.3g of glycidyl methacrylate to continue the reaction for 5 hours; after the reaction, centrifuge and...

Embodiment 2

[0074] Adjust the reaction monomer glycidyl methacrylate in Example 1 to the substance in Table 1, and keep the others consistent with Example 1 to obtain Poly@V-SiO 2 .

[0075] The resulting Poly@V-SiO 2 Carry out a performance test, the test results are as follows:

[0076] Table 1 Poly@V-SiO obtained from different reaction monomers 2 performance characterization

[0077]

[0078] Note: The water contact angle in the table refers to the angle of water on the hydrophobic surface constructed by particles.

Embodiment 3

[0080] Adjust the amount of the reaction monomer glycidyl methacrylate in Example 1 as shown in Table 2, and keep the others consistent with Example 1 to obtain Poly@V-SiO 2 .

[0081] The resulting Poly@V-SiO 2 Carry out a performance test, the test results are as follows:

[0082] Table 2 Poly@V-SiO obtained from different reaction monomers 2 performance characterization

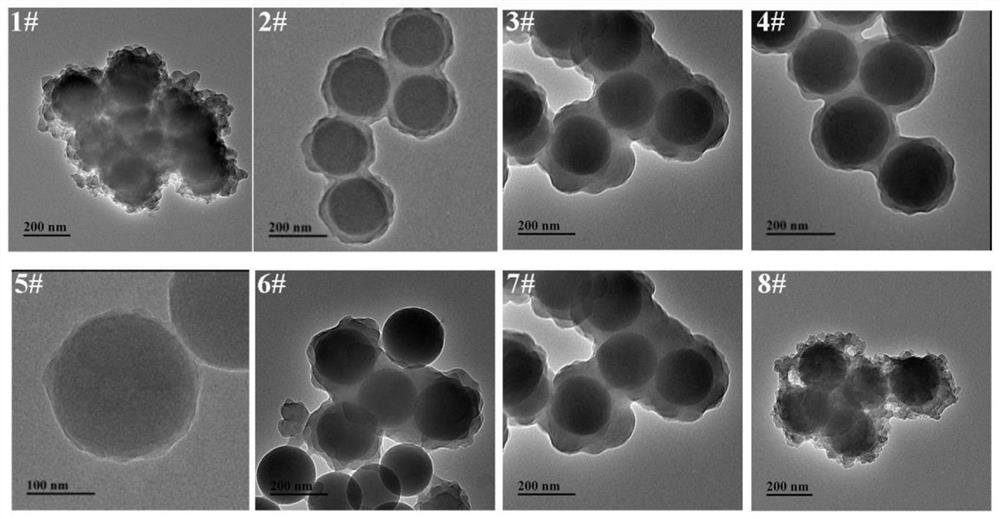

[0083] The amount of glycidyl methacrylate (g) Particle size (nm) appearance Water contact angle (°) 5#0 300 Thin shell, many cores are not covered 141 6#0.15 400 Incomplete core-shell structure 148 7#0.3 (embodiment 1) 450 regular core shell 152 8#0.45 600 Irregular core shell, some monomer self-polymerization 150

[0084] Note: The water contact angle in the table refers to the angle of water on the hydrophobic surface constructed by particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com