Method for preparing organic diamine from organic amide and device thereof

A technology of organic amides and organic diamines, applied in the field of organic synthesis, can solve the problems of difficulty in obtaining high-purity 6-aminocapronitrile, high cost of large-scale production, low conversion rate of raw materials, etc., and achieve high selectivity of aminonitrile organic compounds , extended service life, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0311] The preparation method of catalyst A1 is carried out according to CN111659463A, except that in the molding step, a mold matching with catalyst A1 is used for molding to form catalyst A1 with a specific structure, other preparation methods are carried out according to CN111659463A.

[0312] Catalyst A2 to Catalyst A4 have the same structure and preparation method as Catalyst A1, except that the molar ratios of silicon, aluminum and phosphorus are 1:0.8:0.5, 1:0.8:0.8 and 1:0.8:1.6.

[0313] Catalyst B1

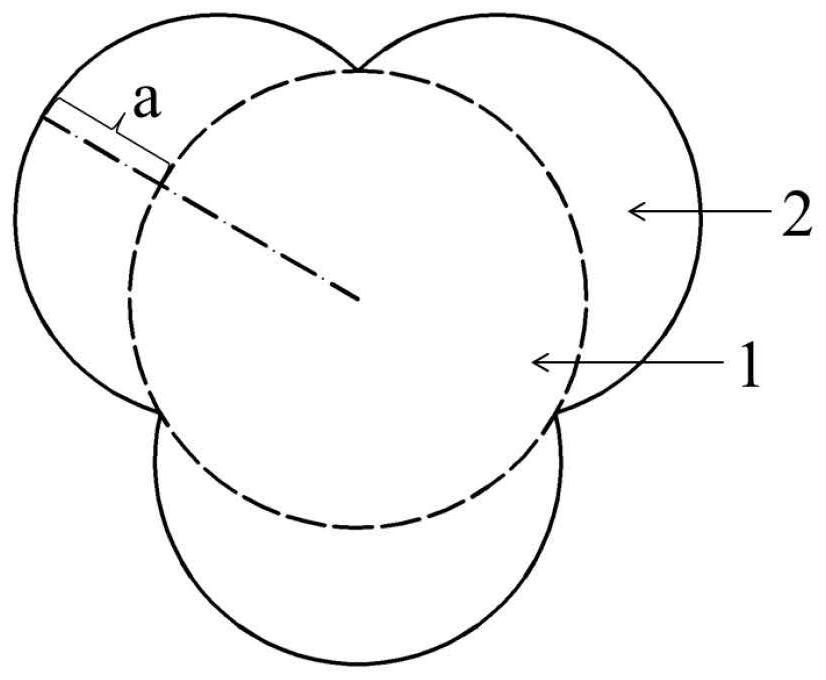

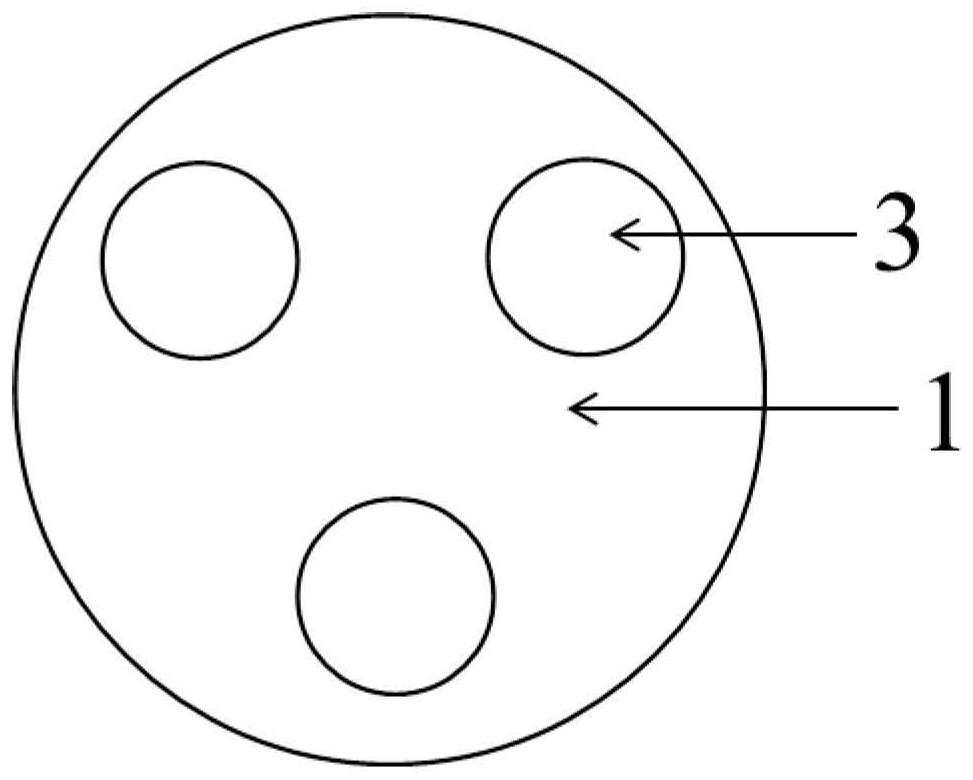

[0314] Catalyst B1 is a clover-shaped columnar catalyst. The clover-shaped catalyst includes a cylindrical body 1 and a protrusion 2, wherein the height of the cylinder is 5 mm, and the lobes outside the clover circle intersection are used as the protrusion 2, Specific as figure 1 As shown, the inside of the dotted line is marked as the main part of the catalyst, and the part outside the dotted circle is marked as the protruding part 2. The diameter of the dotted line c...

Embodiment 1

[0382] This embodiment provides a method for preparing hexamethylenediamine from caprolactam, such as Figure 8-10 As shown, the device used in the method includes a gasification unit 10, an ammoniation reaction unit 20, a first refining unit 30, a first adsorption unit 40, a hydrogenation reaction unit 50, a second refining unit 60 and a second refining unit 60 connected in sequence. Adsorption unit 70.

[0383] The gasification unit 10 includes a Venturi gasification device. The Venturi gasification device comprises a converging section 101, a throat 102 and a diverging section 103, the converging section 101 is provided with a first inlet 104, and the diverging section 103 is provided with a first gas outlet 105, so The throat 102 is provided with a second inlet. The Venturi gasification device also includes an external circulation pipeline connecting the diverging section 103 and the throat 102 . A material conveying device 106 is arranged on the external circulation pi...

Embodiment 2

[0399] This embodiment provides a method for preparing hexamethylenediamine from caprolactam, said method comprising the steps of:

[0400] (1) Isopropyl distearoyloxyaluminate (accounting for 20 ppm by weight of ammonia gas) is mixed with ammonia gas and preheated at 600° C. to superheat the ammonia gas to obtain a mixed gas.

[0401] The mixed gas and the first part of the organic amide in the liquid phase state at a temperature of 220 ° C are mixed and gasified at 500 ° C in the Venturi gasification device, and then passed into the first fixed-bed reactor (a total of 4 fixed-bed reactors in series) , counted as 4 sections of fixed-bed reactors, each section of fixed-bed reactors is filled with catalysts of the same weight), reacting at the first reaction temperature, the first reaction pressure and the first catalyst, to obtain the first reaction discharge;

[0402] The i-th reaction output and the i+1 part of the organic amide are passed into the i+1 section fixed-bed reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com