High-electric-conductivity and high-heat-conductivity bacterial cellulose/graphene composite paper and preparation method thereof

A composite technology of bacterial cellulose and graphene, applied in the field of electrical and thermal conductivity functional paper, can solve the problems of inability to precisely control the performance of composite paper, and the inability to determine the growth amount of graphene, and achieve good mechanical properties, reduced energy consumption, and high content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

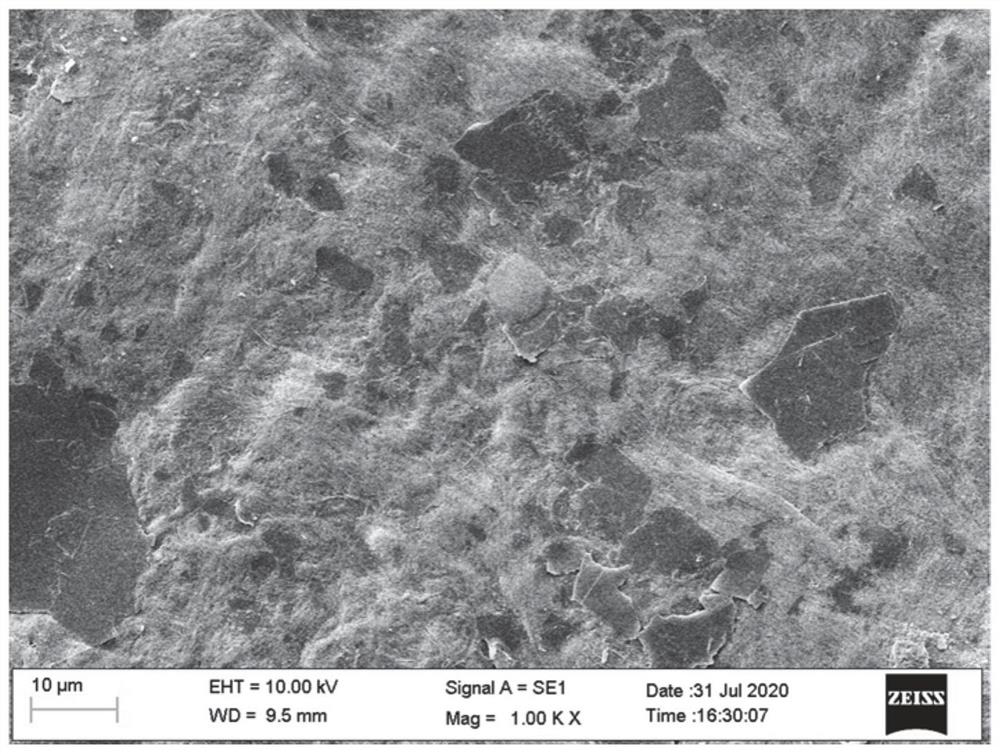

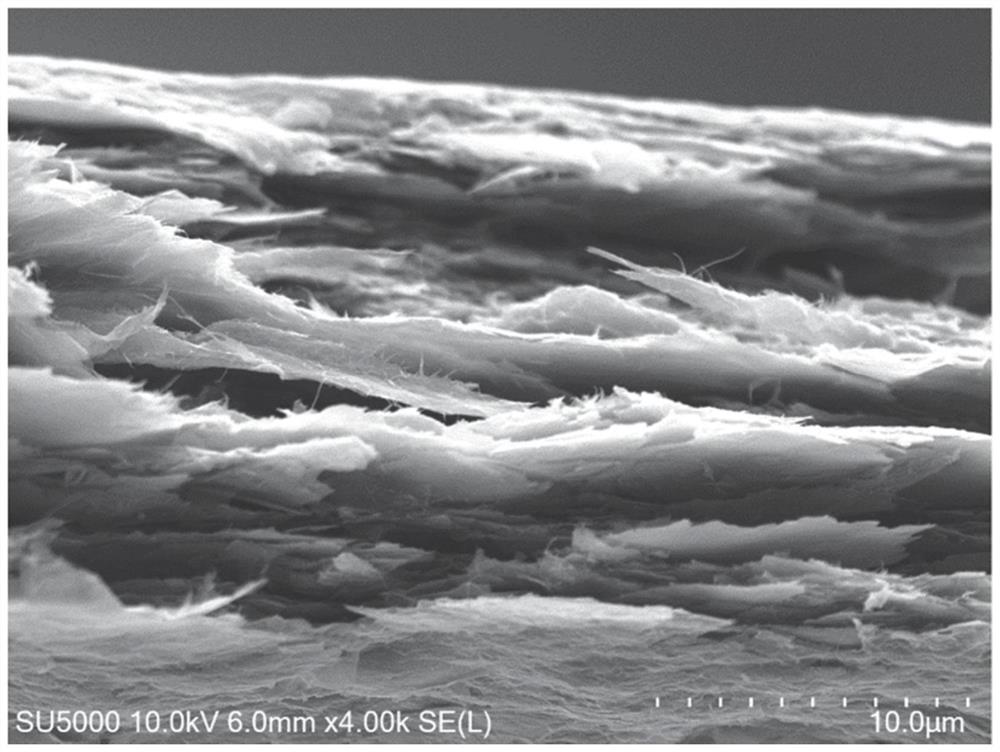

Image

Examples

Embodiment 1

[0042] Bacterial cellulose is secreted by the bacteria Gluconacetobacter. The main components of the bacterial culture medium are: ultrapure water 250mL, sucrose 5g, ammonium sulfate 1.25g, magnesium sulfate 0.125g, potassium dihydrogen phosphate 0.05g, sodium acetate trihydrate 1.24g, citric acid 0.25g, mannitol 0.5g, Disodium hydrogen phosphate dodecahydrate 0.063g, adjust the pH value to 4.5 with acetic acid, and sterilize at 100°C for 30min. A static fermentation culture method is adopted, the culture medium is placed in a container, inoculated with 8% (V / V) gluconacetobacter, and the temperature is 30° C. for static culture for 7 days. The obtained bacterial cellulose wet film had a solid content of 1.5 wt%.

[0043]Take 200g of bacterial cellulose wet film with a solid content of 1.5wt%, place it in an oven and dry it at 60°C to dryness; take 3g of dry bacterial cellulose, cut it into pieces, and put it in 600g of ultrapure water, Soak for 1 h; use a standard pulp defl...

Embodiment 2

[0049] Take bacterial cellulose leftovers, put them in an oven at 60°C and dry them to dryness; take 3g of dry bacterial cellulose, cut them into pieces, soak them in 375g ultrapure water for 1.5h; use a standard pulp deflaker The bacterial cellulose was dispersed to obtain a uniformly dispersed bacterial cellulose dispersion with a concentration of 0.8 wt%.

[0050] Get 250g bacterial cellulose dispersion, add 15g graphene dispersion (concentration is 10wt%), 35mg anionic starch (Hangzhou Paper Friends Technology Co., Ltd., model is YZ-171), 120mg gamma-polyglutamic acid, 40mg phthalate di-n-butyl formate, stirred for 1 hour, and ultrasonically treated for half an hour to obtain a mixed dispersion.

[0051] Put the polyethylene (PE) film as the substrate on the scraper coating machine, take 60g of the prepared mixed dispersion and transfer it to the PE film, adjust the height of the scraper to 1.6mm, and the forward speed to 1.5m / min, push the scraper, and the bacteria fiber ...

Embodiment 3

[0055] Bacterial cellulose is secreted by the bacteria Gluconacetobacter. The main components of the bacterial culture medium are: ultrapure water 250mL, sucrose 5g, ammonium sulfate 1.25g, magnesium sulfate 0.125g, potassium dihydrogen phosphate 0.05g, sodium acetate trihydrate 1.24g, citric acid 0.25g, mannitol 0.5g, Disodium hydrogen phosphate dodecahydrate 0.063g, adjust the pH value to 4.5 with acetic acid, and sterilize at 100°C for 30min. Adopt static fermentation culture method, culture medium is placed in container, inoculate 8% (V / V) gluconacetobacter, temperature is 30 DEG C and cultivate statically for 7 days, the bacterial cellulose wet film solid content that obtains is 1.5wt% .

[0056] Take 200 g of bacterial cellulose wet film with a solid content of 1.5 wt%, and place it in an oven at 60° C. to dry to absolute dryness. Take 3 g of absolutely dry bacterial cellulose, cut it into pieces, soak it in 500 g of ultrapure water for 0.5 h, use a standard pulp disin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com