Soil heavy metal pollution barrier layer material as well as preparation method and application thereof

A technology for barrier materials and heavy metals, which is applied in the field of soil heavy metal pollution barrier layer materials and their preparation, can solve the problems of airtightness, water and nutrients cannot flow effectively, and polymer materials are difficult to degrade, and can increase the density and ratio of micropores. Surface area, simplified modification and activation steps, and the effect of facilitating large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

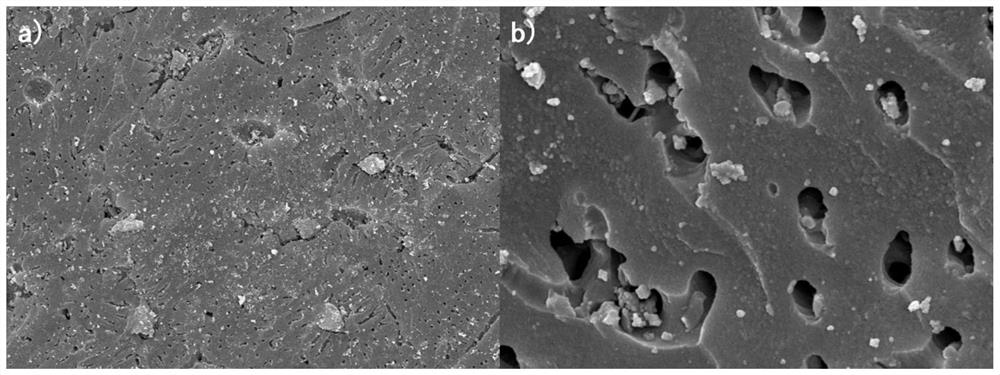

Image

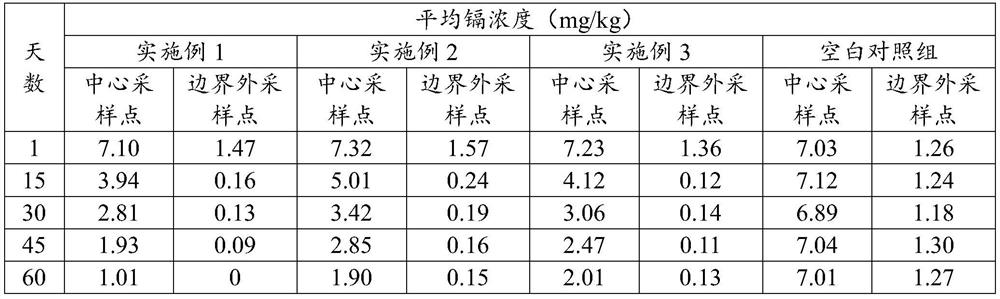

Examples

Embodiment 1

[0029] Preparation of barrier layer material of heavy metals

[0030] 1, 120 parts of the urea-formaldehyde resin, 5 parts of graphite powder and 5 parts of aluminum potassium sulfate dodecahydrate mixed, pulverized after drying 120 deg.] C;

[0031] 2, the mixed powder prepared in Step 1 was heated in a nitrogen atmosphere at 800 deg.] C and held 3h, then cooled to room temperature;

[0032] 3, the product prepared in Step 2 was added 30 parts of potassium hydroxide and 25 parts of zinc chloride, uniformly mixed and ground, then the first phase of heating in a nitrogen atmosphere at a heating rate of 7 ℃ / min was heated to 600 ℃, then heating the second stage of heating at a ramp rate 3 ℃ / min from 600 deg.] C to 800 deg.] C, after incubation 2h, cooled to room temperature;

[0033] 4, using 2mol / L HCl solution, and deionized water of the product prepared in Step 3 was washed, i.e., the barrier material to give heavy metal contaminated soil.

Embodiment 2

[0035] Preparation of barrier layer material of heavy metals

[0036] 1, 110 parts of the urea-formaldehyde resin, 3 parts of graphite powder and 1 part of potassium aluminum sulfate dodecahydrate mixed, pulverized after drying 110 deg.] C;

[0037] 2, the mixed powder prepared in Step 1 was heated in a nitrogen atmosphere at 600 deg.] C and held IH, cooled to room temperature;

[0038] 3, the product prepared in Step 2 was added 25 parts of potassium hydroxide and 20 parts of zinc chloride, uniformly mixed and ground, then the first phase of heating in a nitrogen atmosphere at a heating rate of 5 ℃ / min was heated to 550 deg.] C, then heating the second stage at a heating rate of 2 ℃ / min heated from 550 deg.] C to 700 deg.] C, after incubation IH, cooled to room temperature;

[0039] 4, using 1mol / L HCl solution, and deionized water of the product prepared in Step 3 was washed, i.e., the barrier material to give heavy metal contaminated soil.

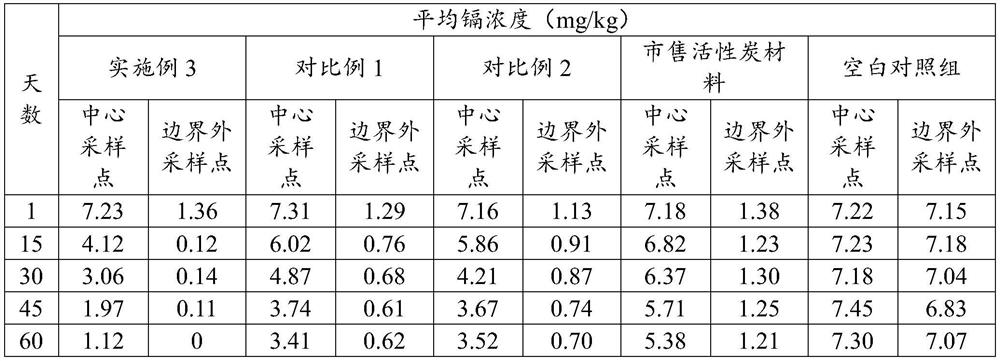

Embodiment 3

[0041] Preparation of barrier layer material of heavy metals

[0042] 1, 115 parts of the urea-formaldehyde resin, 4 parts of graphite powder and 3 parts of potassium aluminum sulfate dodecahydrate mixed, pulverized after drying 115 deg.] C;

[0043] 2, the mixed powder prepared in Step 1 was heated in a nitrogen atmosphere and kept at 700 deg.] C 1.5h, then cooled to room temperature;

[0044] 3, the product prepared in Step 2 was added 27 parts of potassium hydroxide and 23 parts of zinc chloride, uniformly mixed and ground, then the first phase of heating in a nitrogen atmosphere at a heating rate of 6 ℃ / min was heated to 570 ℃, then heating the second stage of heating at a heating rate of 2.5 ℃ / min from 570 ℃ to 750 ℃, after incubation 1.5h, cooled to room temperature;

[0045]4, using a 1.5 mol / L of HCl solution and deionized water to prepare the product prepared in step 3, that is, the soil heavy metal contaminated barrier layer material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com