Hydroxyapatite coating based on polyether-ether-ketone and preparation method thereof

A technology of hydroxyapatite and polyether ether ketone, applied in coatings, pharmaceutical formulations, prostheses, etc., can solve the problem of hydroxyapatite crystal morphology and size control without significant progress, hydroxyapatite coating The preparation method has not been reported, and the coated bone tissue is insufficiently bonded. It has good application prospects, avoids implantation stress shielding, and has the effect of low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a polyether ether ketone-based hydroxyapatite coating provided in an embodiment of the present invention includes the following steps:

[0032] 1) Base material preparation:

[0033] According to the mass ratio (12~10): 1, polyetheretherketone powder and Ca(OH) 2 Powder mixing, ball milling, heat treatment after tablet molding, the temperature is 280-300°C, the holding time is 2h, and polyether ether ketone and Ca(OH) 2 Mixed composite substrate materials;

[0034] 2) Pretreatment of composite substrate materials:

[0035] The composite base material was polished and polished with 2500# and 5000# sandpaper in sequence, and then placed in acetone, alcohol, deionized water and alcohol solution for ultrasonic cleaning for 10-20 minutes respectively to remove surface dirt, and then air-dried naturally to obtain a composite base;

[0036] 3) Preparation of hydrothermal solution: at room temperature, sodium glycerophosphate C with a concentration of ...

Embodiment 1

[0042] 1) Mix polyetheretherketone PEEK powder with Ca(OH) 2 The powder is mixed at a ratio of 10:1, ball milled, pressed into tablets, and heat treated at 300°C for 2 hours to obtain a composite substrate;

[0043] 2) Grind and polish the composite substrate with 2500#, 5000# sandpaper in sequence, and then place it in acetone, alcohol, deionized water and alcohol solution for ultrasonic cleaning for 10 minutes respectively;

[0044] 3) Add 0.2mol / L of C 3 h 7 Na 2 o 6 P, 2mol / L of C 10 h 12 CaN 2 Na 2 o 8 Dissolve in deionized water, add 0.02mol / L NaOH to adjust the pH value to 7, stir until the hydrothermal solution is transparent and set aside;

[0045] 4) Put the prepared hydrothermal solution and the composite substrate into the reaction kettle, keep it at 170°C for 15 hours, and complete the hydrothermal deposition;

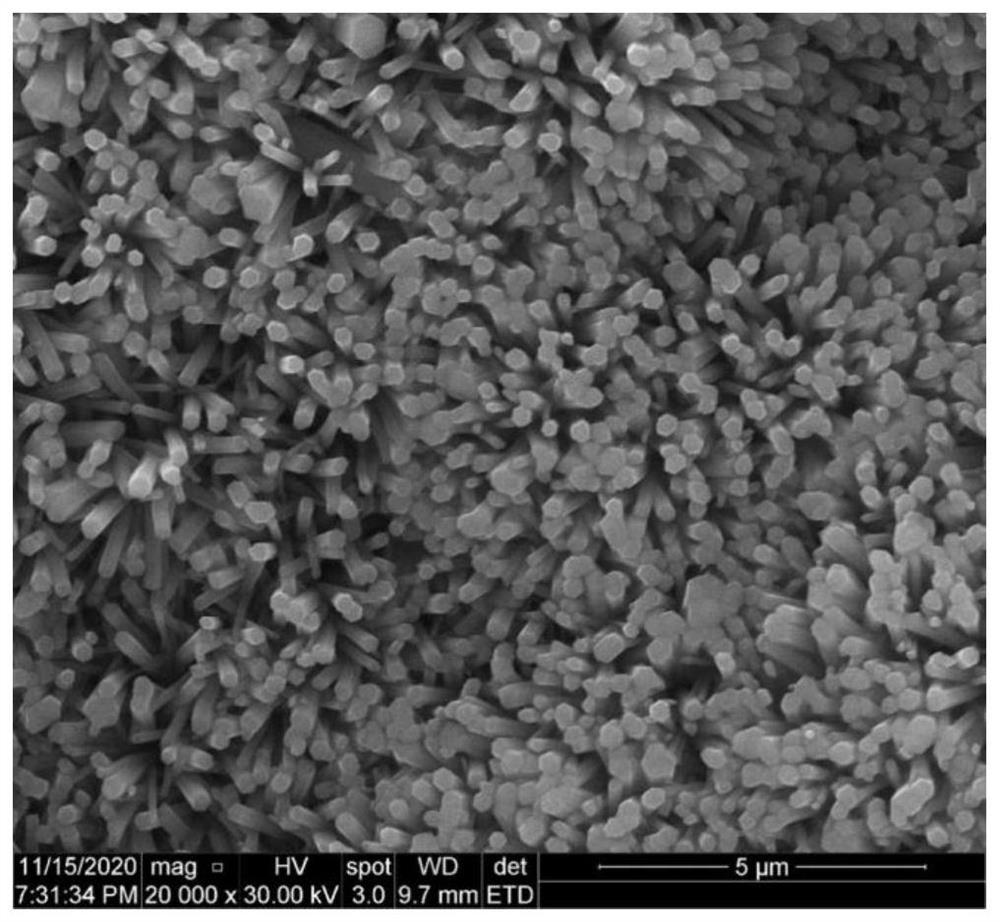

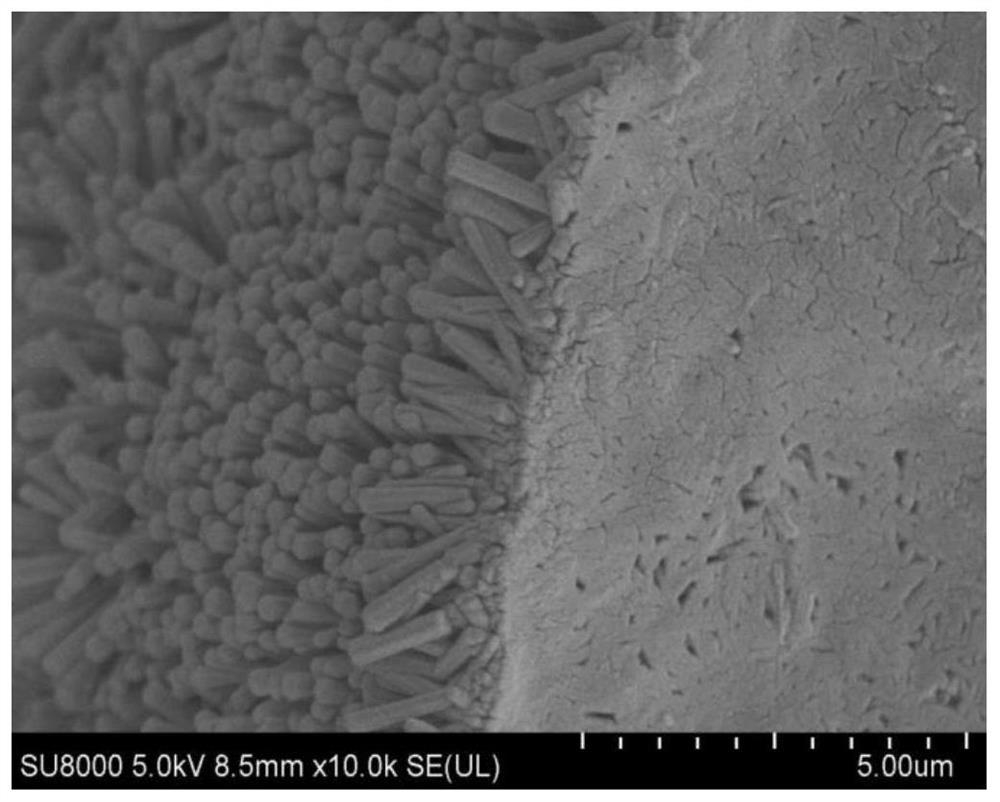

[0046] 5) Take out the sample, rinse it with water, keep it in an oven at 70°C for 20 minutes, and obtain the mixture in PEEK and Ca(OH) 2 Hydr...

Embodiment 2

[0049] Polyetheretherketone PEEK powder and Ca(OH) 2 The powder is mixed at a ratio of 10:1, ball milled, and tabletted, then heat-treated at 280°C for 2 hours to obtain a composite substrate;

[0050] 2) Grind and polish the composite substrate with 2500#, 5000# sandpaper in turn, and then place it in acetone, alcohol, deionized water and alcohol solution for ultrasonic cleaning for 20 minutes respectively;

[0051] 3) Add 0.2mol / L of C 3 h 7 Na 2 o 6 P, 2mol / L of C 10 h 12 CaN 2 Na 2 o 8 Dissolve in deionized water, add 0.02mol / L NaOH to adjust the pH value to 6, stir until the hydrothermal solution is transparent and set aside;

[0052] 4) Put the prepared hydrothermal solution and the composite substrate into the reaction kettle, keep it at 180°C for 5 hours, and complete the hydrothermal deposition;

[0053] 5) Take out the sample, rinse it with water, keep it in an oven at 60°C for 30 minutes, and obtain the mixture in PEEK and Ca(OH) 2 Hydroxyapatite coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com