Covalent organic framework catalyst as well as preparation method and application thereof

A covalent organic framework and catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of uneven distribution of active components and uneven adsorption capacity Advanced problems, to achieve the effect of short preparation time, simple process, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a method for preparing covalently-organic framework catalyst, comprising the steps of:

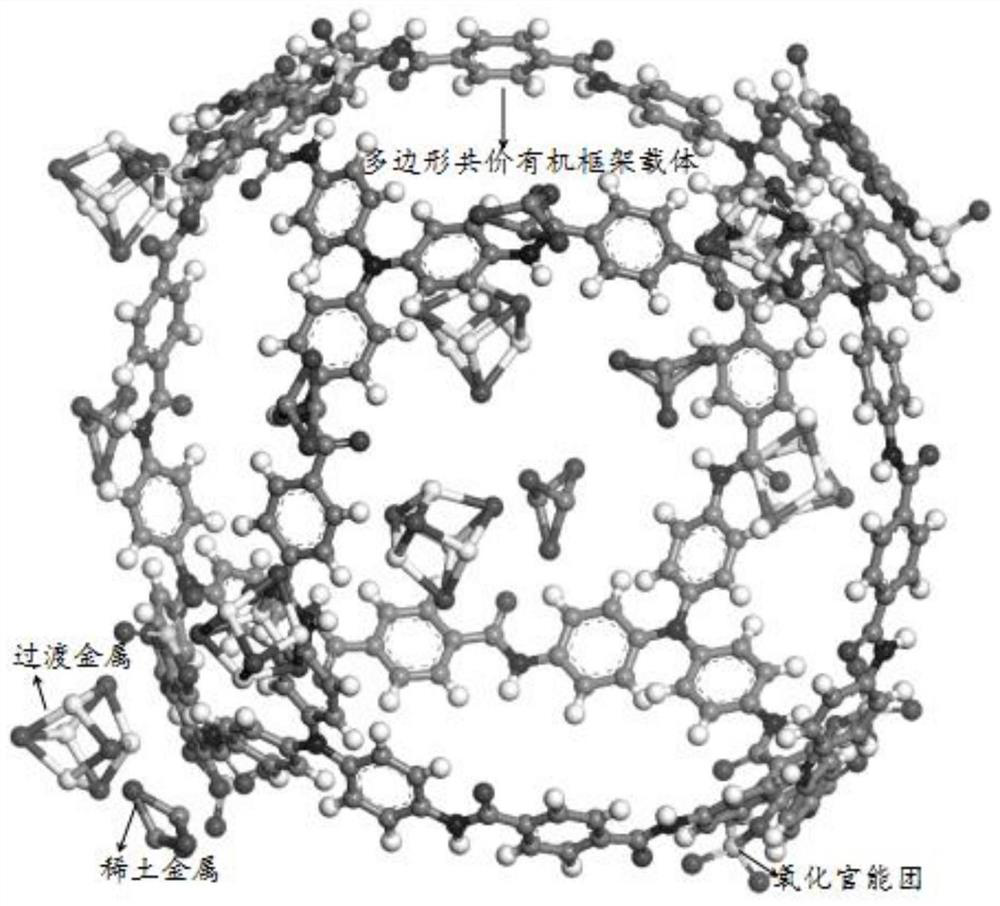

[0026] Mixing the first small molecule proton formaldehyde precursor, three amino anilines ligand and a solvent, a condensation reaction, to give a covalent organic frameworks polygonal vehicle; the small molecule-based formaldehyde precursor for the phthalaldehyde, trimesic pyromellitic formaldehyde or formaldehyde;

[0027] The polygon covalent organic vehicle frame, and a second metal oxide nano-protic solvent mixture, load, type of load to obtain covalent organic framework material; nano-sized metal oxide comprises nano transition metal oxide and rare earth metal oxide thing;

[0028] The supported covalent organic framework materials, sodium sulfate solution, and the third mixed protic solvent, a substitution reaction, to give a covalent organic framework catalyst.

[0029] Unless otherwise specified, the present invention has no special requirements ...

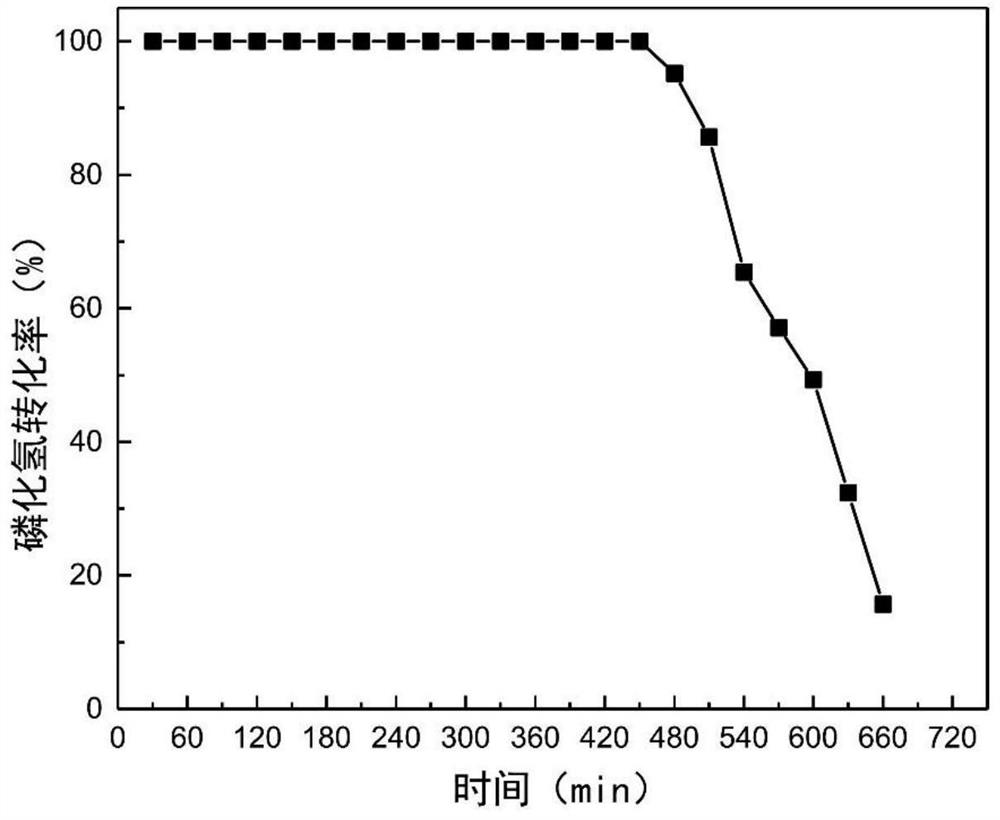

Embodiment 1

[0063] Terephthalic dialdehyde and 4,4 ', 4 "- triamino triphenylamine molar ratio of 1: 0.5 mixture dissolved in DMF, was stirred at room temperature for 30min, stirring rate 500r / min, and then placed in a rotary evaporator obtained polygon covalent organic frameworks vehicle rotary evaporation at 95 deg.] C for 45 min, evaporated to dryness and crystallized; the polygons covalent organic frameworks support, the nano metal oxide particles (Fe 2 O 3 And CeO 2The mass ratio is 100: 2) is mixed in anhydrous ethanol according to mass ratio 20: 2, stirred at room temperature for 10 min, and the rate of stirring is 600 r / min, then placed in a rotary evaporator at 50 ° C to steam 30min The evaporation crystallization is obtained by a covalent organic frame material; the load type is covalently organically organic frame material, sodium sulfate, sulfuric acid solution (0.5% mass concentration) is mixed according to mass ratio 100: 2.5: 1 mixed in anhydrous ethanol. The mixture was st...

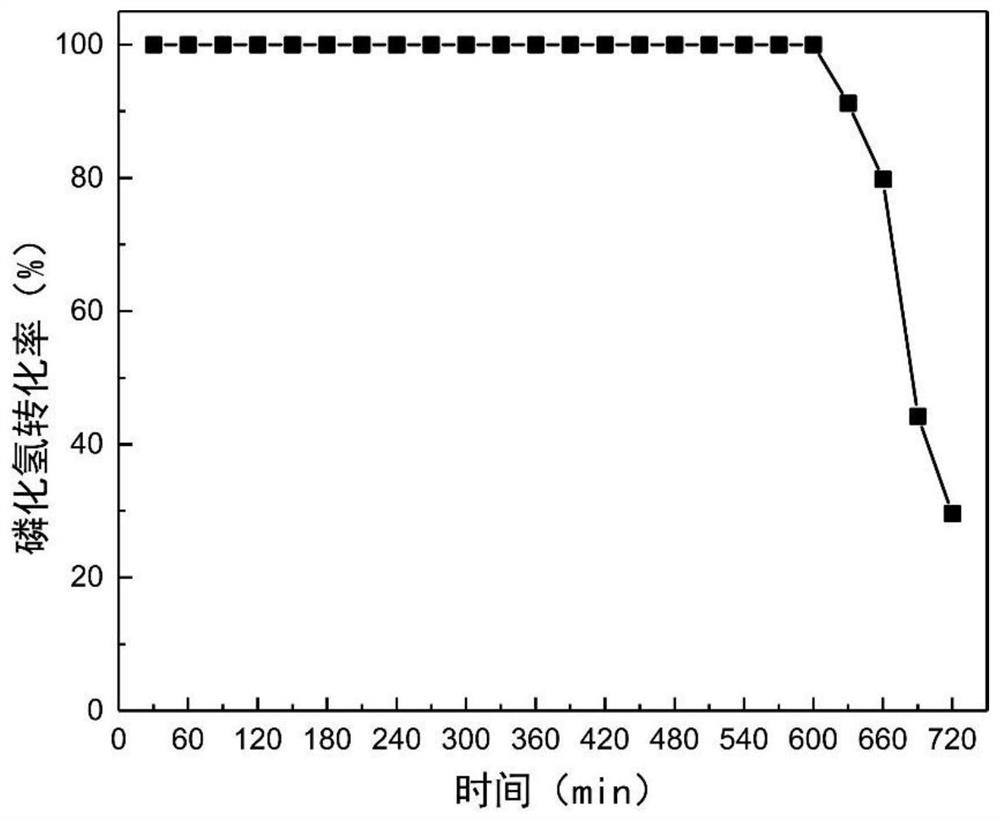

Embodiment 2

[0065] The ion benzophenylmeraldehyde and 4, 4, 4 "- trisopenamine were mixed in DMF by mixing in DMF, stirred at room temperature for 30 min, and stirred at a rate of 1000 r / min, then placed in a rotary evaporator In 80 ° C, evaporation of 20 min, evaporate crystallization to give a polygon covalent organic frame carrier; covalent organic frame carrier, nano metal oxide particles (Cuo and CEO) 2 The mass ratio is 100: 10) is mixed in anhydrous ethanol by mass ratio 20: 1, stirred at room temperature for 8 min, and the rate of stirring is 1200 r / min, then placed in a rotary evaporator at 60 ° C to steam 20 minutes. The evapoction crystallization is obtained by a covalent organic frame material; the load type is covalently organically organic frame material, sodium sulfate, sulfuric acid solution (1.5% mass concentration) is mixed in a mass ratio of 100: 5: 2 mixed in anhydrous ethanol. The mixture was stirred at room temperature for 10 min, and the stirred rate was 500 r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com