Composite biological patch as well as preparation method and application thereof

A biological patch and drug technology, applied in the medical field, can solve the problems of poor adherence, no pore structure, unsatisfactory mechanical properties, etc., and achieve the effects of low cost and simple and convenient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] In some preferred embodiments, the preparation method of the hydrophobic porous layer comprises the following steps:

[0080] Dissolve hydrophobic nanocellulose in organic reagents, then add anti-infective drugs, mix and form a film;

[0081] Preferably, the organic reagent includes but not limited to hexafluoroisopropanol and / or ethanol;

[0082] Preferably, the ratio of the hydrophobic nanocellulose to the organic reagent is 1g:(4-8)mL, such as, but not limited to, 1g:4mL, 1g:5mL, 1g:6mL, 1g:7mL or 1g: 8mL;

[0083] Preferably, in terms of mass percentage, the added amount of the anti-infective drug is 5%-10% of the hydrophobic nanocellulose, such as, but not limited to, 5%, 6%, 7%, 8%, 9% or 10%;

[0084] Preferably, the film-making method includes but is not limited to electrospinning, or other film-making methods well known to those skilled in the art;

[0085] Preferably, the hydrophobic porous layer has a thickness of 0.5-2 mm, for example, but not limited to...

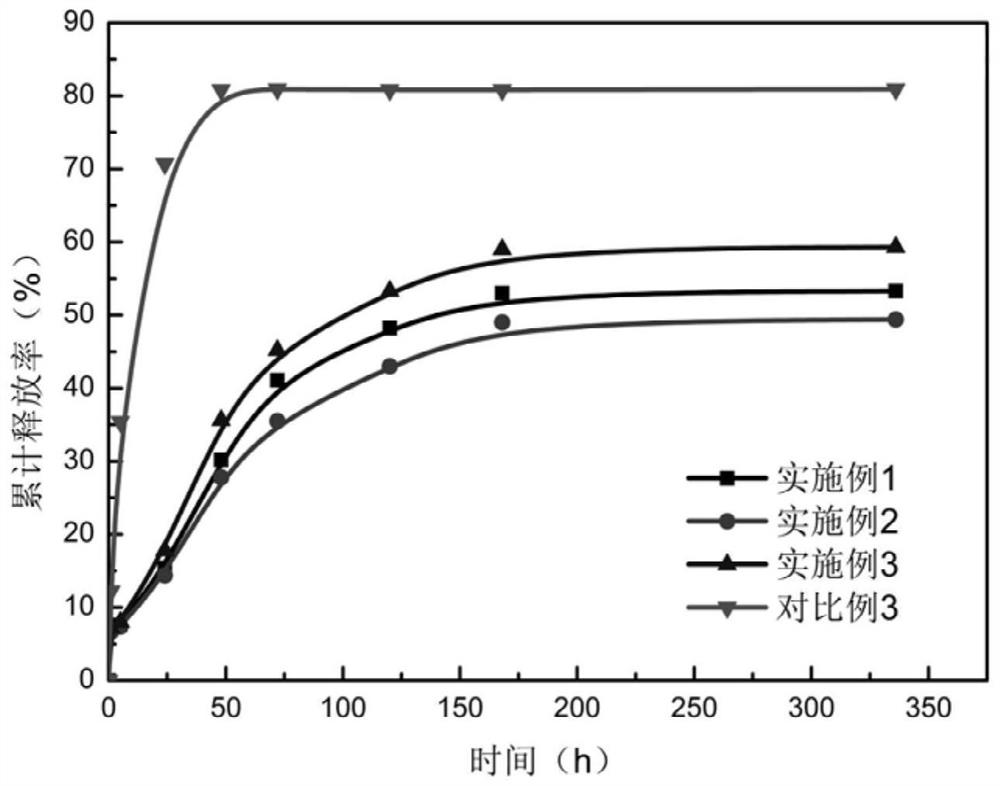

Embodiment 1

[0140] A composite biological patch, its preparation method is as follows:

[0141] 1. Preparation of hydrophobic porous layer: Take a certain amount of ethyl cellulose and dissolve it in hexafluoroisopropanol solvent, the addition ratio is 1g:6mL, stir for 36 hours to prepare a spinning solution with a concentration of 9.5%, and then add anti The infection drug ketoprofen was added in a proportion of 8% of the ethyl cellulose, and then the stirring was continued for 60 hours to obtain a spinning solution containing an anti-infection drug. Put the spinning liquid into the syringe, connect the needle to high voltage, the receiving device is aluminum foil, the spinning voltage is 15kV, the spinning rate is 0.3mL / h, the receiving distance is 15cm, the spinning time is 3h, and the fiber with a thickness of 1mm is obtained Then the obtained nanofiber membrane was dried in a vacuum oven at 80° C. overnight to remove residual solvent.

[0142] 2. Preparation of type Ⅰ collagen porou...

Embodiment 2

[0152]A composite biological patch, its preparation method is as follows:

[0153] 1. Preparation of the hydrophobic porous layer: Take a certain amount of ethyl cellulose and dissolve it in the solvent absolute ethanol, the addition ratio is 1g:4mL, stir for 24-48h and prepare a spinning solution with a concentration of 24.1%, and then add anti The infection drug ketoprofen was added in a proportion of 5% of the ethyl cellulose, and then the stirring was continued for 48 hours to obtain a spinning solution containing an anti-infection drug. Put the spinning solution into the syringe, connect the needle to high voltage, the receiving device is aluminum foil, the spinning voltage is 10kV, the spinning rate is 0.1mL / h, the receiving distance is 13cm, the spinning time is 1h, and the thickness is 0.5mm. Cellulose nanofiber membrane, and then place the obtained nanofiber membrane in a vacuum oven at 80° C. to dry overnight to remove residual solvent.

[0154] 2. Preparation of ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com