Fast-fired colorful pearlescent glaze, rock plate and preparation method of rock plate

A pearlescent and colorful technology, used in manufacturing tools, ceramic molding machines, etc., can solve the problems of no longer pearlescent effect, limited application range, etc., to achieve excellent visual effects, reduce high temperature decomposition, and inhibit crystal growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Fast-firing colorful pearlescent glazes, including pearlescent glazes, pearlescent glazes include the following raw materials:

[0035] 35-40 parts of perlite, 20-25 parts of boric acid, 6-10 parts of strontium carbonate, 6-10 parts of zirconia, 2-6 parts of chalk, 4-8 parts of zircon, 3-8 parts of high boron frit , 2-6 parts of lithium fluoride, 6-10 parts of cerium oxide, and 1-3 parts of corundum.

[0036] The chemical composition of pearlescent glaze includes the following components in mass percentage:

[0037] SiO 2 40-50 wt%, Al 2 o 3 8-12 wt%, Fe 2 o 3 0.5-4.0wt%, ZnO 8-12wt%, CaO 2-5wt%, MgO 0-0.5wt%, K 2 O 1-3wt%, Na 2 O 1-4wt%, SrO 5-10wt%, ZrO 2 4-8wt%, B 2 o 3 12-18wt%, loss on ignition 0-10wt%.

[0038] It also includes pearlescent bottom glaze, which includes the following raw materials:

[0039] Potassium feldspar 25-35 parts, albite 15-25 parts, quartz powder 20-25 parts, nepheline 6-12 parts, barium carbonate 4-8 parts, alumina 5-8 parts, d...

Embodiment 2

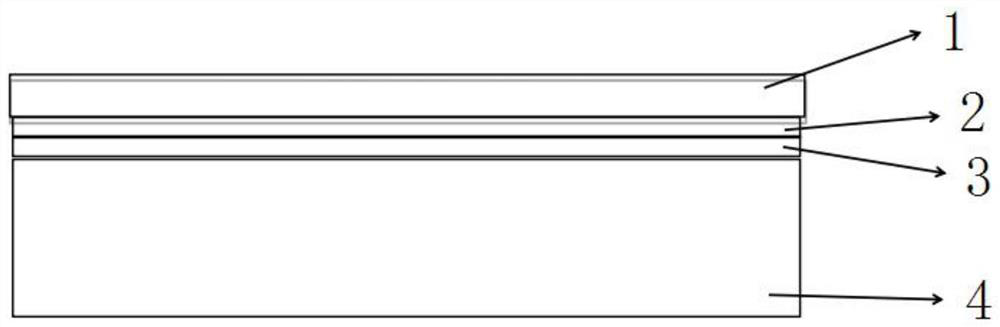

[0052] Such as figure 1 As shown, the fast-fired colorful pearlescent slate, the fast-fired colorful pearlescent glaze of Example 1 is applied, including the pearlescent glaze 1, the auxiliary pattern layer 2, the pearlescent bottom glaze 3 and the slate blank 4 arranged from top to bottom.

[0053] Among them, the components of 4 parts by weight of the slate blank are preferably: 1.5-3.5 parts of water abrasive, 18.0-22.0 parts of washed ball clay, 2.0-4.0 parts of ultra-white ball clay, 1.0-3.0 parts of black talc, 36.0-41.0 parts of water scrub 16-20.0 parts of public sand, 8.0-12.0 parts of high-temperature sand, 1.0-2.0 parts of bentonite, 2-4 parts of calcined bauxite; more preferably: 2.0-3.0 parts of water abrasive, 19.0-21.0 parts of washed ball clay, super 2.5-3.5 parts of white ball clay, 1.5-2.5 parts of black talc, 38.0-40.0 parts of water scrub, 17.0-19.0 parts of public sand, 9.0-11.0 parts of high-temperature sand, 1.0-2.0 parts of bentonite, and 2.5-3.5 parts ...

Embodiment 3

[0058] The preparation method of fast-burning colorful pearlite slabs is used for the fast-burning colorful pearlite slabs of embodiment 2, comprising the steps:

[0059] S1, prepare pearlescent glaze, pearlescent bottom glaze and slate blank;

[0060] S2, apply the pearlescent base glaze on the surface of the slate blank and dry it;

[0061] S3. Printing a preset pattern on the surface of the pearlescent base glaze to form an auxiliary pattern layer;

[0062] S4, spraying pearlescent glaze on the surface of the auxiliary pattern layer;

[0063] S5, firing.

[0064] The glazing proportion of the pearlescent glaze is 1.50-1.60, the amount of glazing is 50-80g / pan (the specification of the measuring glazing tray is 600mm*200mm), the thickness of the glaze layer is 0.4-1.0mm; the glazing proportion of the pearlescent base glaze is 1.30-1.40, The amount is 20-30g / pan (the specification of the glaze measuring tray is 600mm*200mm), and the thickness of the glaze layer is 0.02-0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com