Bendable concrete and preparation method thereof

A concrete and bending technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of easy aging, easy corrosion and expansion, rapid deterioration of concrete mechanical properties and long-term durability, and achieve anti-aging. Performance enhancement, flexural properties and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

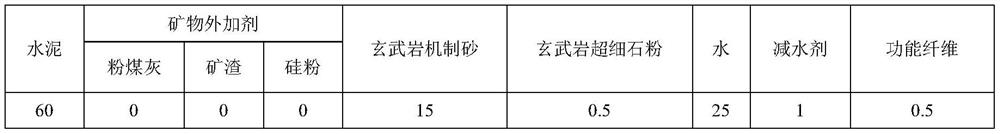

[0044] The material composition ratio is shown in Table 1:

[0045] Table 1 Mixing ratio of bendable concrete materials (mass parts)

[0046]

[0047] The cement is P·O 42.5 ordinary Portland cement; the nominal maximum particle size of basalt machine-made sand is 1.25mm, and the fineness modulus is 2.3; 608; The water reducing agent is a polycarboxylate high-performance water reducing agent, and the water reducing rate is 25%;

[0048] The functional fibers are basalt fibers impregnated with a mixed solution of silane coupling agent and calcium carbonate whiskers, and then dried. Specifically, strong magnetic stirring (stirring speed: 1000r / min) and ultrasonic vibration dispersion (working frequency 20~ 25KHz, ultrasonic power 300W), first disperse the calcium carbonate whiskers into the silane coupling agent solution at 40°C, and then add the basalt fiber to the mixed solution of silane coupling agent and calcium carbonate whiskers;

[0049] The equivalent diameter of b...

Embodiment 2

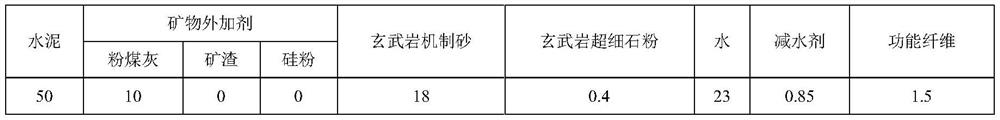

[0053] The material composition ratio is shown in Table 2:

[0054] Table 2 Proportions of bendable concrete materials (mass parts)

[0055]

[0056] The cement is P·II 42.5 Portland cement; the fly ash is F class I fly ash; the nominal maximum particle size of basalt machine-made sand is 1.25mm, and the fineness modulus is 1.0; It is tap water for drinking; the silane coupling agent is KH-792; the water reducing agent is polycarboxylate high-performance water reducing agent, and the water reducing rate is 26%;

[0057] The functional fibers are basalt fibers impregnated with a mixed solution of silane coupling agent and calcium carbonate whiskers and then dried. Specifically: first, stir with strong magnetic force (stirring speed: 800r / min) and disperse with ultrasonic vibration (working frequency 20 ~ 25KHz, ultrasonic power 500W), the calcium carbonate whiskers are first dispersed in the silane coupling agent solution at 60°C, and then the basalt fibers are added to the...

Embodiment 3

[0061] The material composition ratio is shown in Table 3:

[0062] Table 3 Proportions of bendable concrete materials (mass parts)

[0063]

[0064] The cement is P·I 42.5 Portland cement; the fly ash is Class F Class II fly ash; the slag is S75 class slag; the nominal maximum particle size of basalt machine-made sand is 1.25mm, and the fineness modulus is 1.4; basalt superfine stone powder is 45μm The sieve residue is zero; the water is drinking tap water; the silane coupling agent is KH-892; the water reducing agent is polycarboxylate high-performance water reducing agent, and the water reducing rate is 26%;

[0065] The functional fibers are basalt fibers impregnated with a mixture of silane coupling agent and calcium carbonate whiskers and then dried. Disperse into silane coupling agent solution at 50°C, then add basalt fiber to the mixed solution of silane coupling agent and calcium carbonate whisker for impregnation;

[0066] The equivalent diameter of basalt fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com