MoS2 nanosheet vertically embedded biochar nano composite material, and preparation method and application thereof

A nano-composite material and bio-carbon technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of slow electron transfer rate, influence on electron transfer, and reduction of active sites, and achieve Good cycle stability and reversibility, increase the contact area, alleviate the effect of volume pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

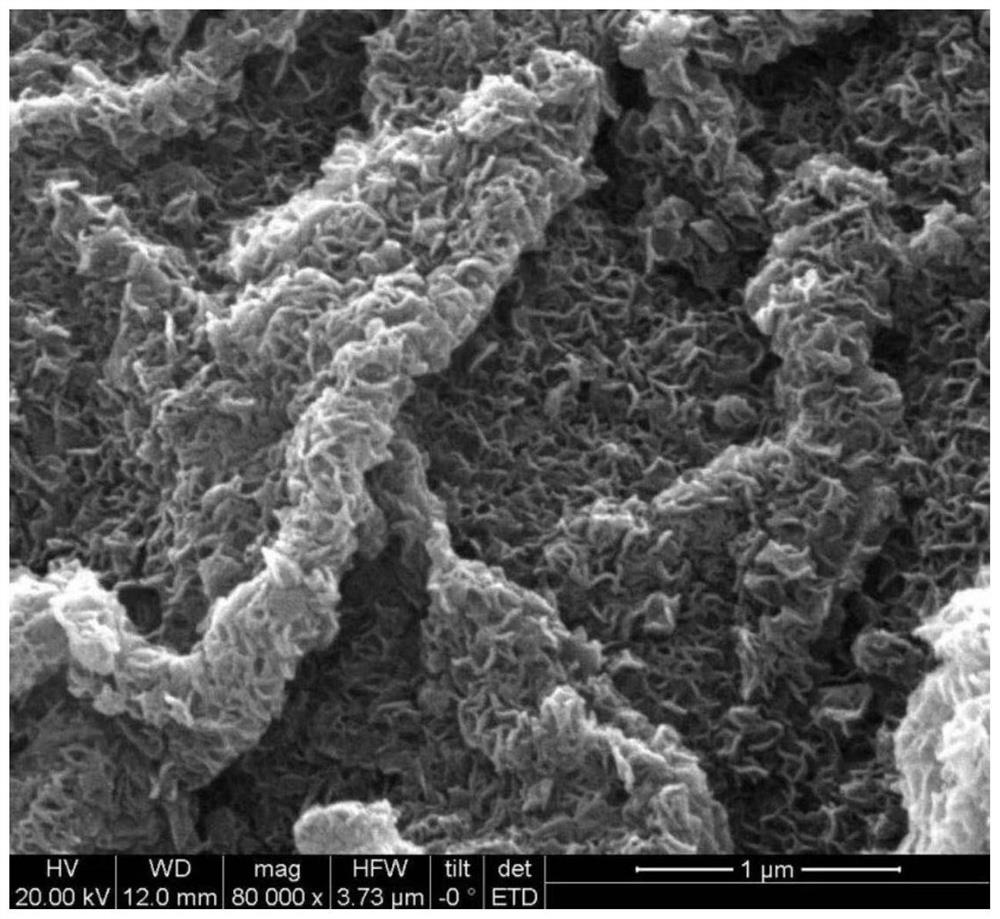

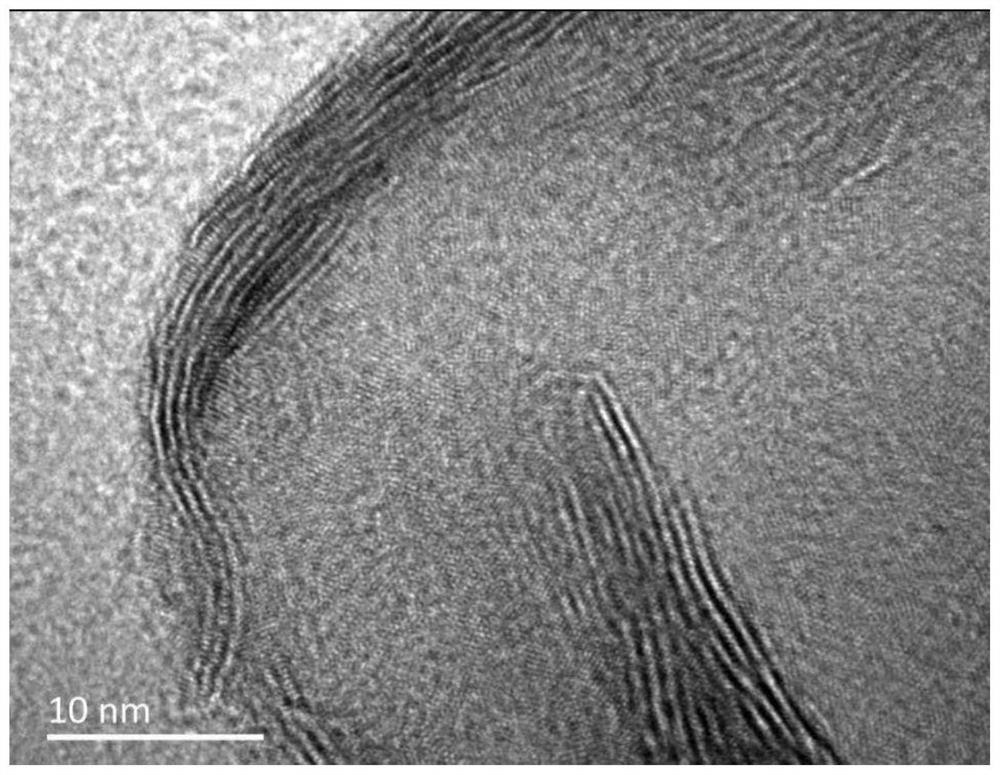

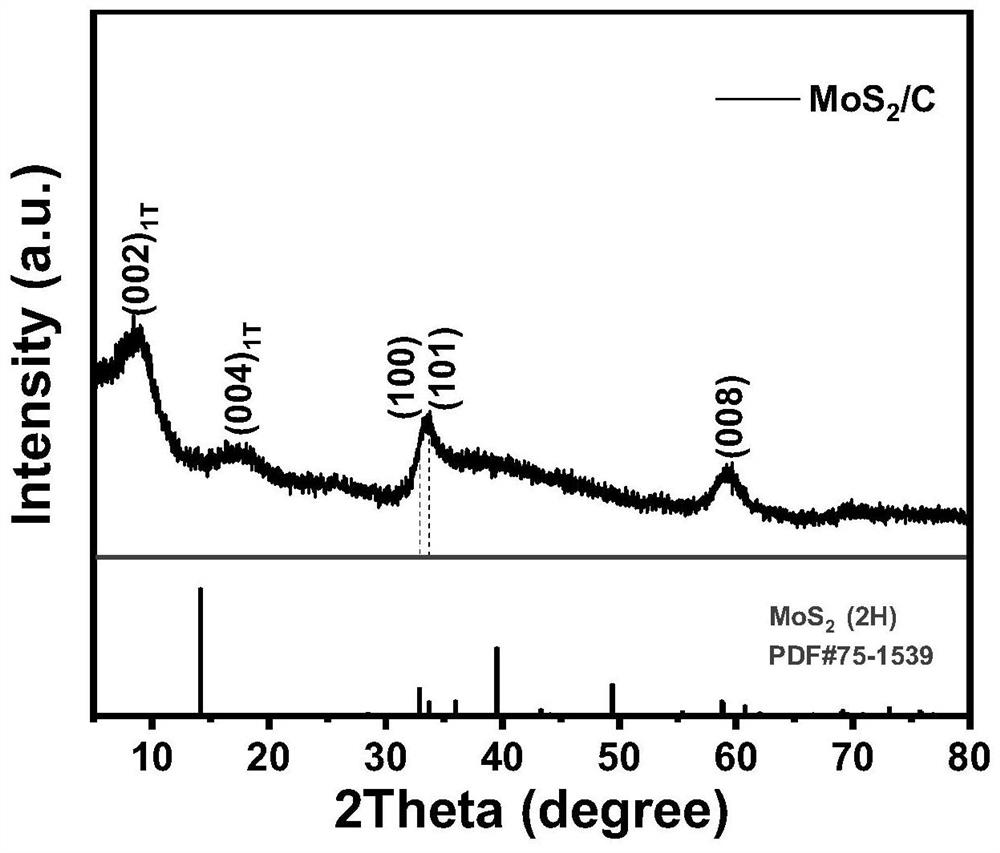

[0035] A kind of MoS 2 A method for preparing a bio-carbon nanocomposite material vertically embedded in nanosheets, comprising the following steps:

[0036] (1) Camellia petals were collected from the campus and washed with deionized water to remove surface dust. The petals were then soaked in aqueous ethanol (50%) for 2 weeks to remove pigments and other organic matter from the petals.

[0037] (2) Wash the pretreated petals 3 times with deionized water, dry them, and then immerse them in a mixed solution of ammonium molybdate and 0.028moL / L thiourea with a concentration of 0.0075moL / L. Afterwards, the ammonium molybdate and thiourea were used to infiltrate the bio-template and transferred to the lining of the reactor, and heated at 220° C. for 6 hours.

[0038](3) Suction filter the mixture after hydrothermal treatment, wash with deionized water and ethanol three times respectively, and put the obtained solid product into an oven at 80° C. for 24 hours. This sample is a ...

Embodiment 2

[0047] (1) Camellia petals were collected from the campus and washed with deionized water to remove surface dust. The petals were then soaked in aqueous ethanol (50%) for 2 weeks to remove pigments and other organic matter from the petals.

[0048] (2) The pretreated petals were washed with deionized water for 3 times, dried, and then immersed in a mixed solution of ammonium molybdate and 0.114moL / L thiourea with a concentration of 0.029moL / L. Afterwards, the ammonium molybdate and thiourea were used to infiltrate the bio-template and transferred to the lining of the reactor, and heated at 220° C. for 6 hours.

[0049] (3) Suction filter the material after hydrothermal treatment, wash with deionized water and ethanol three times, and put the obtained solid product into an oven at 80°C for 24 hours. This sample is a partially carbonized petal / MoS 2 .

[0050] (4) Part of the dried carbonized petals / MoS 2 Place in a tube furnace and calcinate at 550°C for 2 hours under nitro...

Embodiment 3

[0053] (1) Peach blossom petals were collected from the campus and rinsed with deionized water to remove surface dust. The petals were then soaked in aqueous ethanol (50%) for 2 weeks to remove pigments and other organic matter from the petals.

[0054] (2) The pretreated petals were washed with deionized water for 3 times, dried, and then immersed in a mixed solution of ammonium molybdate and 0.114moL / L thiourea with a concentration of 0.029moL / L. Afterwards, the ammonium molybdate and thiourea were used to infiltrate the bio-template and transferred to the lining of the reactor, and heated at 220° C. for 6 hours.

[0055] (3) Suction filter the material after hydrothermal treatment, wash with deionized water and ethanol three times, and put the obtained solid product into an oven at 80°C for 24 hours. This sample is a partially carbonized petal / MoS 2 .

[0056] (4) Part of the dried carbonized petals / MoS 2 Placed in a tube furnace and calcined at 550°C for 2 hours under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com