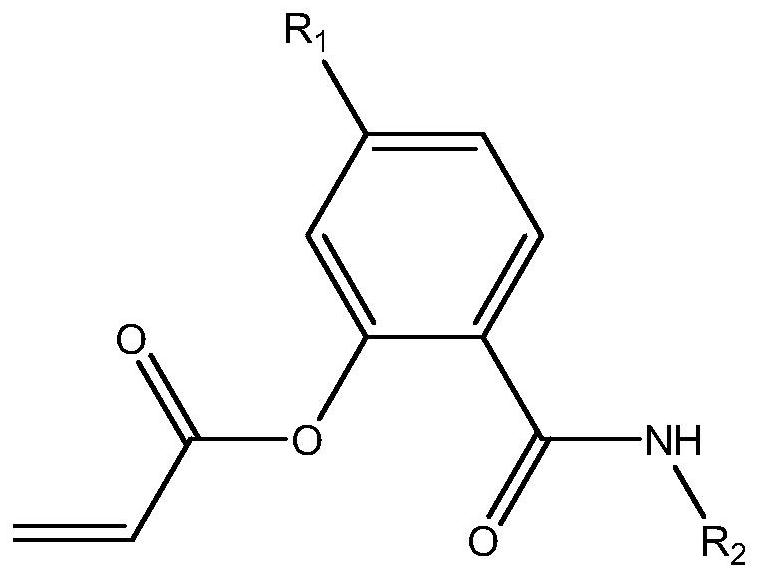

Acrylate amide anti-fouling agent and preparation method thereof

An ester-based amide and acrylate-based technology, which is applied in the field of acrylate amide antifouling agents and their preparation, can solve problems such as difficult degradation, marine environmental pollution, and high toxicity, and achieve anti-fouling organisms, simple preparation methods, The effect of controlling the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

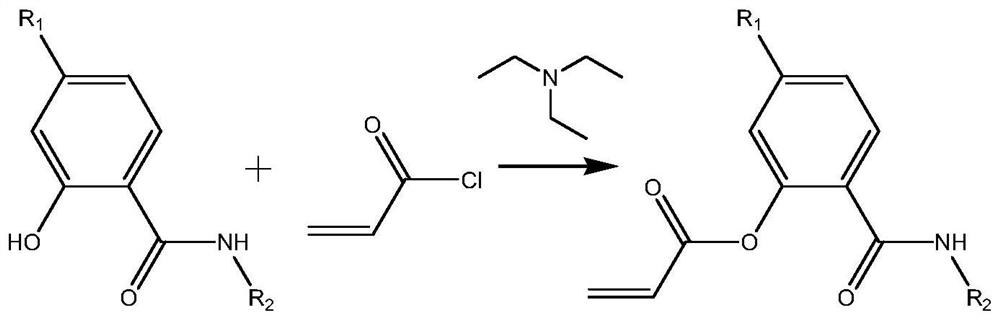

[0026] The technical process of the preparation method of the acrylate amide antifouling agent involved in the present invention comprises four steps of preparation, dripping, post-treatment and column chromatography:

[0027] (1) Preparation: Slowly add 50mmol of salamide antifouling agent, 60mmol of triethylamine and 25ml of dichloromethane into a three-necked flask to form a mixed system;

[0028] Slowly add 55mmol of acryloyl chloride and 25ml of dichloromethane into the constant pressure funnel to form a mixed solution;

[0029] (2) Dropping: feed nitrogen into the mixing system, and stir the mixing system at a speed of 500r / min under the condition that the temperature of the water bath is 20°C. After feeding nitrogen for 30 minutes, add the mixed solution dropwise to the mixing system to control The rate of addition is such that the dripping process of the mixed solution continues for 1.5 hours, and after the mixed solution and the mixed system react for 12 hours, the re...

Embodiment 2

[0033] This embodiment relates to the structural characterization of the acrylate amide antifouling agent prepared in Example 1:

[0034] Use NICOLETAVATAR-360 type infrared spectrophotometer to test the white needle-like crystals, get as follows image 3 In the infrared spectrogram shown, the ordinate is the transmittance (%), and the abscissa is the wave number (cm -1 ), of which, 3331.29cm -1 N-H stretching vibration absorption peak, 3000-2800cm -1 It is saturated C-H stretching vibration, 1735.34cm -1 It is the carbonyl absorption peak, 1639.50cm -1 It is the C=0 stretching vibration absorption peak in the amide group, 1606.25cm -1 、1573.00cm -1 and 1449.52cm -1 Both are benzene ring skeleton vibrations, 755.47cm -1 It is the C-H out-of-plane bending vibration, that is, the characteristic peak of the ortho-position substitution of the benzene ring, which is consistent with the molecular structure of Example 1.

[0035] Use the Bruker ultrafleXtreme MALDI TOF / TOF ma...

Embodiment 3

[0039] This example relates to the anti-fouling performance test of the acrylate amide antifouling agent prepared in Example 1 on diatoms: the acrylate amide antifouling agent was prepared with ethanol or DMSO to make 12.5 μg / ml and 50 μg / ml respectively and 200μg / ml 3 concentrations of A solution, add a pre-cut round glass slide to the microwell plate, add algae liquid, A solution and solvent (ethanol or DMSO) to the microwell plate, and place it in an artificial climate In the box, under the constant temperature condition of 23°C, standard culture light is adopted (6:00 am-6:00 pm, provide 5000lux light source irradiation; 6:00 pm-6:00 am the next morning, keep dark environment) After 72 hours, gently wash away the unattached algae on the round glass slide with sterilized seawater, observe the attachment of diatoms on the round glass slide with a fluorescence microscope, take random fluorescence photos of five fields of view, and use image pro to analyze the diatoms in the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com