Zinc oxide nano material and preparation method thereof, electron transport film and light emitting diode

A zinc oxide nanometer and electron transport technology, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of poor dispersion stability of zinc oxide nanomaterials, achieve good film uniformity and increase the band gap , Improve the effect of stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

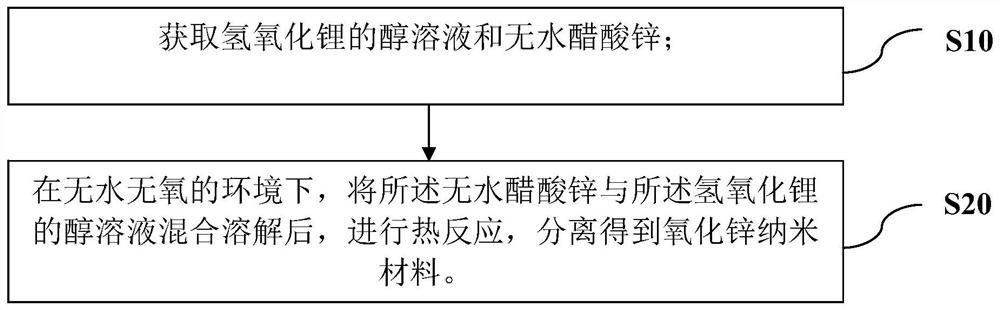

[0028] as attached figure 1 As shown, the embodiment of the present invention provides a preparation method of zinc oxide nanomaterials, comprising the following steps:

[0029] S10. Obtain lithium hydroxide solution and anhydrous zinc acetate;

[0030] S20. In an anhydrous and oxygen-free environment, after mixing and dissolving the anhydrous zinc acetate and the lithium hydroxide solution, conduct a thermal reaction to separate and obtain zinc oxide nanomaterials.

[0031] The preparation method of the zinc oxide nanomaterial provided in the embodiment of the present invention uses lithium hydroxide and anhydrous zinc acetate as raw materials, and prepares the zinc oxide nanomaterial through thermal reaction in an anhydrous and oxygen-free environment. On the one hand, the embodiments of the present invention consider the adverse effects of water and oxygen on the stability of zinc oxide, and use anhydrous zinc acetate as the zinc source to synthesize in an anhydrous and ox...

Embodiment 1

[0061] A zinc oxide solution (ZnO ①), comprising preparation steps:

[0062] 1. In an argon glove box, first take 7 mmol of lithium hydroxide solid and dissolve it in 60 mL of ethanol solution, put it into a round bottom flask for 3 hours of ultrasound, heat it to 80 ° C after the end, cover the bottle and use a magnet Stirring is carried out to obtain a lithium hydroxide precursor solution.

[0063] 2. Put the weighed 7.7mmol of anhydrous zinc acetate solid into the lithium hydroxide precursor solution, keep it at 80°C and stir it with a magnet for 20 minutes.

[0064] 3. After the reaction is over, put the round bottom flask containing the mixed solution into ice water for ice bathing. After cooling down to 10°C, divide it into eight centrifuge tubes (7.5mL / tube) and add 40mL of n-heptane . Shake the mixed solution and put it in an ice bath for 30 minutes, then centrifuge at 6000rpm for 5 minutes, pour off the supernatant after centrifugation and disperse with 2.5mL / tube e...

Embodiment 2

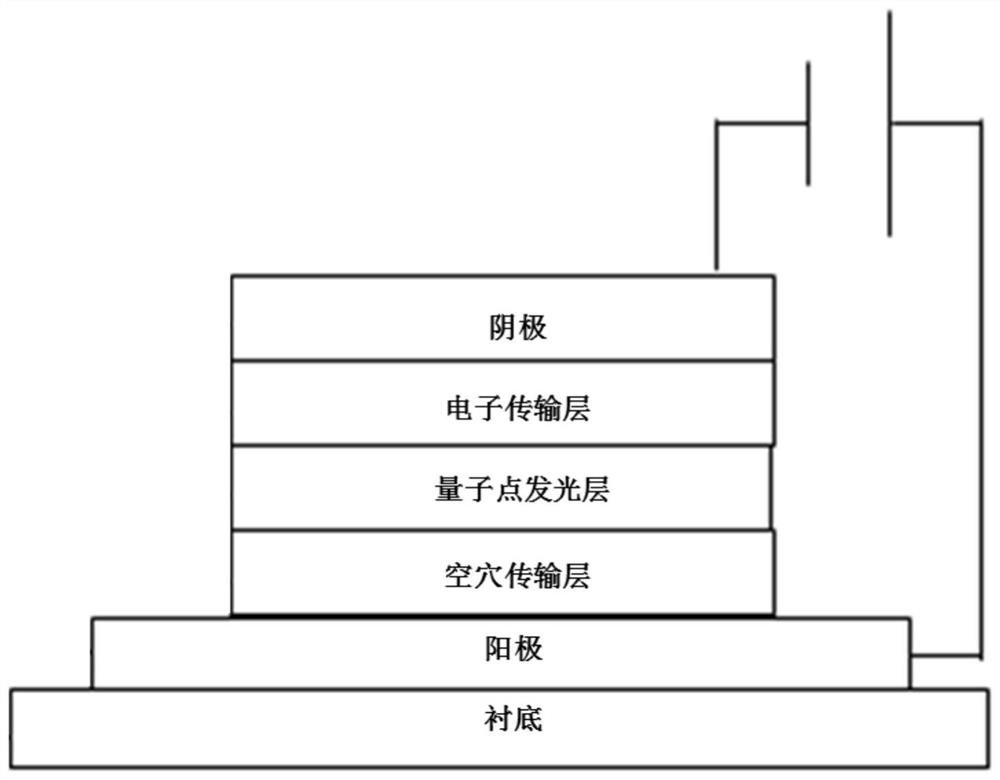

[0080] For quantum dot light-emitting diodes, the zinc oxide solution prepared in Example 1 is stored in a refrigerator, and the device is prepared by using the same process as follows every 7 days, and the device prepared by storing the zinc oxide solution for different times is obtained, including steps:

[0081] 1. Spin-coat a layer of PEDOT:PSS:s-MoO on the ITO substrate 3 hole injection layer and annealed in air;

[0082] 2. In a nitrogen atmosphere, spin-coat a 25nm PVK hole transport layer on the hole injection layer and anneal at 140°C;

[0083] 3. Spin-coat a layer of 35nm CdSe@ZnS quantum dot luminescent layer on the hole transport layer;

[0084] 4. The zinc oxide solution prepared in Example 1 was spin-coated on the quantum dot luminescent layer on the 1st day, the 8th day, the 15th day and the 22nd day to form a ZnO electron transport layer with a thickness of 50 nm;

[0085] 5. Evaporate 100nm Ag electrode on the electron transport layer;

[0086] 6. Obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy gap | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com